Get in touch with us

Leave a message

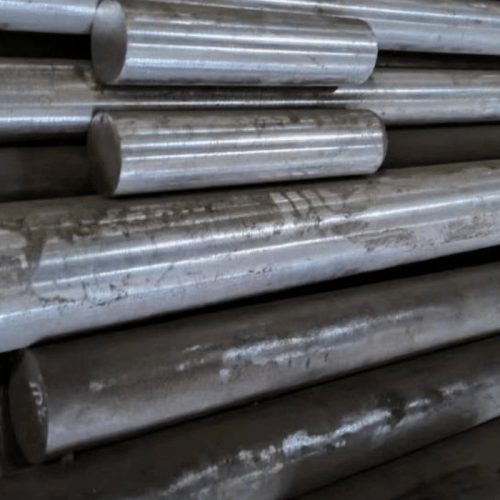

The 1J22 Cobalt Alloy Bar is a high-performance cobalt based alloy designed for applications requiring exceptional magnetic properties and strength. Renowned for its cobalt alloy properties, this round bar offers high saturation magnetization, corrosion resistance, and durability. Manufactured by our trusted China factory, it is ideal for aerospace, electrical, and industrial applications.

For competitive pricing on 1J22 Cobalt Alloy Bar, connect with our sales team for a customized quote. Pricing terms are flexible, based on order volume and specifications. Contact our China-based enterprise to discuss your needs.

The 1J22 Cobalt Alloy Bar is widely used in industries requiring high-performance cobalt base alloy, including:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | 48-50% |

| Iron (Fe) | 48-50% |

| Vanadium (V) | 1.8-2.2% |

| Nickel (Ni) | 0.1-0.5% |

| Carbon (C) | ≤0.05% |

| Others (Si, Mn) | Balance |

| Property | Value |

|---|---|

| Tensile Strength | 700-900 MPa |

| Yield Strength | 400-600 MPa |

| Elongation | 15-25% |

| Hardness (HB) | 200-250 |

The 1J22 Cobalt Alloy Bar offers moderate resistance to acids (e.g., dilute sulfuric acid) and alkalis, suitable for mild chemical environments. Its cobalt alloy composition ensures stability in atmospheric conditions. Environmental compliance is met, but recycling is recommended due to cobalt content to adhere to regulations.

While the 1J22 Cobalt Alloy Bar is highly effective, note the following limitations:

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Urban) | <0.01 |

| Seawater | 0.02-0.03 |

| 5% Sulfuric Acid | 0.05-0.1 |

| 5% Sodium Hydroxide | 0.01-0.02 |

Recommended welding methods for 1J22 Cobalt Alloy Bar include:

Fabrication involves cold drawing or forging for shaping. Machining requires high-speed steel or carbide tools. Annealing may be needed to restore magnetic properties post-fabrication.

The 1J22 Cobalt Alloy Bar from this China manufacturer is perfect for our transformer cores. Its magnetic performance is exceptional.

Mark S.

Electrical Engineer

These bars are reliable and corrosion-resistant. The cobalt alloy price is reasonable for the quality provided.

Lisa W.

Aerospace Technician

Reliable and easy to machine with the right tools. The cobalt based alloys have enhanced our generator efficiency.

James T.

Power Systems Manager

A: Unlike Stellite, 1J22 is optimized for magnetic properties with a high cobalt-iron content, ideal for electrical applications rather than wear resistance.

A: It’s used in aerospace, electrical engineering, and automotive industries for magnetic and high-strength components.

A: Magnetic properties degrade above 750°C, requiring careful application in high-heat environments.

A: TIG and MIG welding are preferred for high-quality joints.

A: Yes, but recycling is advised to manage cobalt content responsibly.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.