Get in touch with us

Leave a message

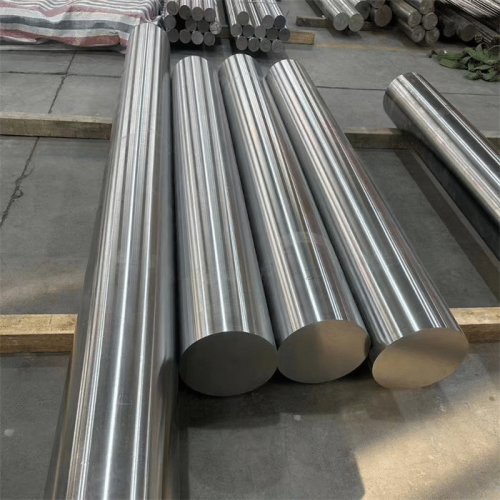

The Stellite 12 Cobalt Alloy Rod is a cobalt-based alloy renowned for its excellent wear resistance, high hardness, and ability to withstand extreme conditions. Unlike Stellite 6 or Stellite 6b, Stellite 12 offers a balance of toughness and abrasion resistance, making it ideal for demanding applications. As a trusted Stellite 12 Cobalt Alloy Rod manufacturer in China, we deliver high-quality rods for industries requiring durability and performance.

Contact our sales team directly for the most competitive pricing on the Stellite 12 Cobalt Alloy Rod. We offer customized quotes for Stellite 12 Cobalt Based Alloy Bar price based on your specific requirements, including dimensions, quantity, and delivery timelines. Contact us today to discuss your needs!

The Stellite 12 Cobalt based Alloy Rod is used in industries requiring wear and corrosion resistance under harsh conditions. Key applications include:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | Balance |

| Chromium (Cr) | 29.0–32.0 |

| Tungsten (W) | 7.0–9.0 |

| Carbon (C) | 1.4–1.9 |

| Nickel (Ni) | 3.0 max |

| Iron (Fe) | 3.0 max |

| Silicon (Si) | 1.5 max |

| Property | Value |

|---|---|

| Tensile Strength | 850 MPa |

| Yield Strength (0.2% offset) | 650 MPa |

| Elongation | 1–3% |

| Hardness (Rockwell C) | 45–50 HRC |

| Density | 8.53 g/cm³ |

Stellite 12 Cobalt Based Alloy Bar exhibits excellent resistance to various corrosive environments:

| Environment | Corrosion Rate (mm/year) | Conditions | Notes |

|---|---|---|---|

| Stagnant Seawater | 0.008 | 25°C, 12 months exposure | Minimal pitting observed |

| 10% Sulfuric Acid | 0.02 | 30°C, 3 months exposure | Good resistance |

| 10% Hydrochloric Acid | 0.03 | 25°C, 1 month exposure | Moderate resistance |

| Atmospheric (Coastal, Humid) | <0.003 | 25°C, 12 months exposure | No significant corrosion |

| 5% Sodium Hydroxide (Alkaline) | 0.01 | 40°C, 3 months exposure | Excellent resistance |

| 5% Nitric Acid | 0.015 | 30°C, 3 months exposure | Superior to Stellite 6 in this condition |

We’ve been using Stellite 12 Cobalt Based Alloy Bar for our valve seats in harsh offshore environments, and the wear resistance is phenomenal. Compared to Stellite 6, it holds up much better under abrasion. This China-based manufacturer delivered consistent quality and fast turnaround.

John K.

Oil & Gas Engineer

The Stellite 12 Cobalt Alloy Bar we sourced for our cutting tools has exceeded expectations. The hardness and thermal stability are perfect for our high-speed applications. Their round bar stock was easy to work with, and the pricing was competitive.

Sarah L.

Industrial Tooling Specialist

This supplier provided us with Stellite 12 Cobalt Alloy Rod for our crusher components, and the durability is unmatched. It outperforms Stellite 6b in abrasive conditions, and their team was great to work with. Highly recommend!

Mike D.

Mining Equipment Manager

A: Stellite 12 Cobalt Based Alloy Bar offers higher hardness and better abrasion resistance than Stellite 6, but with slightly less toughness than Stellite 6b, making it ideal for applications requiring wear resistance over impact resistance.

A: Yes, it performs well up to 800°C, but prolonged exposure to higher temperatures may reduce its hardness and wear resistance.

A: It’s widely used in oil & gas, power generation, chemical processing, mining, and industrial tooling for applications requiring wear and corrosion resistance.

A: Simply contact our sales team with your project details, and we’ll provide a tailored quote for Stellite 12 Cobalt Alloy Bar price within 24 hours.

A: Yes, it offers excellent corrosion resistance in seawater, making it suitable for marine applications like pump components and valve seats.

A: We offer Stellite 12 round bar in hot rolled, ground, polished, or custom finishes. Contact us to discuss the best option for your needs.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.