Get in touch with us

Leave a message

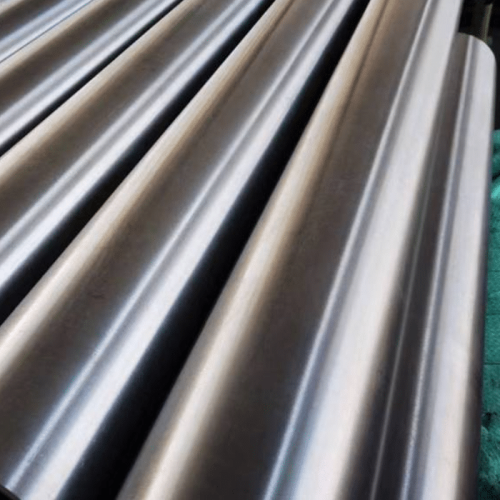

The Stellite 4 Cobalt Alloy Rod is a high-performance cobalt base alloy designed for exceptional wear and corrosion resistance. Known for its durability in extreme conditions, this Round Rod is ideal for industries requiring robust materials, such as aerospace, power generation, and oil and gas. Its unique cobalt alloy composition ensures long-lasting performance.

For competitive pricing on Stellite 4 Cobalt Alloy Rod, contact our sales team. We offer tailored pricing terms for cobalt based alloys, including bulk discounts. Reach out to discuss your needs and receive a personalized quote for your project.

The Stellite 4 Cobalt Alloy Rod is widely used in demanding industries due to its robust cobalt alloy properties. Key applications include:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | Balance |

| Chromium (Cr) | 28.0 - 32.0 |

| Tungsten (W) | 12.0 - 15.0 |

| Carbon (C) | 1.0 - 1.5 |

| Nickel (Ni) | 3.0 max |

| Iron (Fe) | 3.0 max |

| Silicon (Si) | 1.5 max |

| Property | Value |

|---|---|

| Tensile Strength | 800 - 1000 MPa |

| Yield Strength (0.2% Offset) | 600 - 750 MPa |

| Elongation | 10 - 15% |

| Hardness (HRC) | 40 - 48 |

The Stellite 4 Cobalt Alloy Rod offers excellent resistance to corrosive environments, including:

Environmental Restrictions: Avoid prolonged exposure to highly reducing environments or concentrated hydrochloric acid, which may cause pitting.

Despite its strengths, the Stellite 4 Cobalt Alloy Rod has some limitations:

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Industrial) | <0.01 |

| Seawater (Flowing) | 0.02 - 0.05 |

| 10% Sulfuric Acid | 0.1 - 0.4 |

| 5% Phosphoric Acid | 0.05 - 0.2 |

The Stellite 4 Cobalt Alloy Rod supports various fabrication methods. Recommended techniques include:

Tip: Pre-heat to 200°C before welding to minimize cracking, and ensure proper ventilation due to cobalt fumes.

The Stellite 4 Cobalt Alloy Rod we ordered for our drilling tools has exceptional wear resistance. Delivery was prompt, and the quality exceeded expectations.

David R.

Oil and Gas Engineer

We use cobalt chrome rods in our turbines, and these have been incredibly durable. Great supplier with excellent support.

Emily S.

Power Plant Supervisor

The Round Bar performed flawlessly in our high-temperature engine components. Worth the investment for its reliability.

Mark L.

Aerospace Technician

A: Stellite 4 has a balanced cobalt alloy composition with higher tungsten content, offering superior wear resistance compared to Stellite 6, but less ductility.

A: It’s used in aerospace, oil and gas, power generation, and chemical processing for wear- and corrosion-resistant components.

A: Due to its high hardness, machining requires carbide tools and slow speeds, but it’s achievable with proper equipment.

A: Stellite 4 offers better wear and corrosion resistance in extreme conditions but is more expensive and harder to machine.

A: Diameters range from 3 mm to 100 mm, with lengths up to 3000 mm or custom-cut.

A: It’s recyclable and durable, minimizing waste, but cobalt dust from machining requires proper handling to avoid environmental impact.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.