Get in touch with us

Leave a message

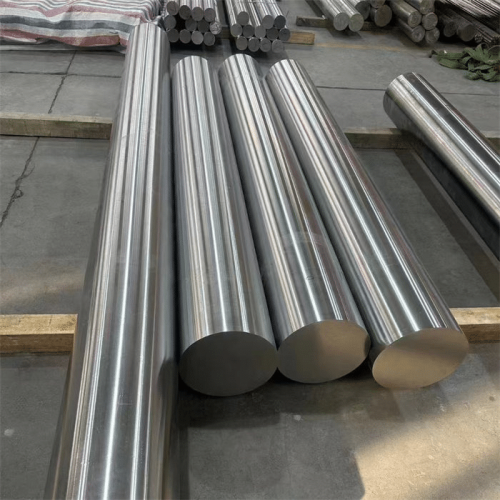

Stellite 3 Cobalt Alloy Rod, a high-performance cobalt chromium alloy, delivers unmatched wear and corrosion resistance. Crafted by our China manufacturer, it’s ideal for extreme industrial applications.

Contact our sales team for a quote on Stellite 3 Cobalt Alloy Rod. Pricing varies by specifications and order volume. Reach out to our China factory for details.

Stellite 3 Cobalt Alloy Rod serves industries like:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | Balance |

| Chromium (Cr) | 29.0 - 31.0 |

| Tungsten (W) | 11.0 - 14.0 |

| Carbon (C) | 2.0 - 2.7 |

| Nickel (Ni) | ≤3.0 |

| Iron (Fe) | ≤3.0 |

| Property | Value |

|---|---|

| Tensile Strength | 1100 MPa |

| Yield Strength | 900 MPa |

| Hardness (HRC) | 48 - 55 |

| Elongation | 1 - 2% |

| Environment | Resistance |

|---|---|

| Atmospheric | Excellent |

| Mild Chemical (pH 5-9) | Good |

| Seawater | Moderate |

Stellite3 Cobalt Alloy Rod has been a game-changer for our turbine components. Its wear resistance is unmatched!

Mark W.

Aerospace Engineer

Reliable material for our oilfield equipment. The cobalt alloy properties hold up in harsh conditions.

Lisa P.

Oil & Gas Manager

Great product from a trusted China manufacturer. Fast delivery and consistent quality.

Tom R.

Industrial Buyer

A: Stellite 3 offers higher carbon content for superior wear resistance compared to Stellite 6.

A: Used in aerospace, oil & gas, and chemical industries for durable components.

A: Yes, up to 800°C, but performance may degrade beyond this.

A: Yes, with low corrosion rates in saline environments.

A: Contact our sales team for a quote tailored to your needs.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.

©2025 alloy-materials.com COPYRIGHT ALL RIGHT RESERVED.