Get in touch with us

Leave a message

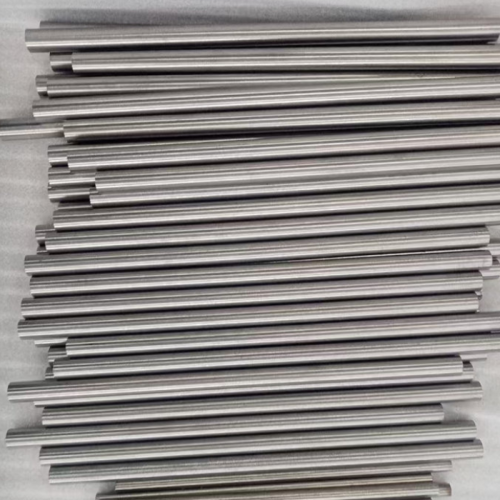

The Stellite31 Cobalt Alloy Rod, a premium cobalt-based alloy, offers exceptional strength, corrosion resistance, and durability. Engineered for demanding environments, this cobalt chromium alloy excels in aerospace, medical, and industrial applications. Its unique cobalt alloy composition ensures reliable performance under high temperatures and harsh conditions.

For pricing details on Stellite31 Cobalt Alloy Rod, please reach out to our sales team. Terms like FOB or CIF can be discussed based on your requirements.

This cobalt chrome round rod is ideal for:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | Balance |

| Chromium (Cr) | 25.0-29.0 |

| Nickel (Ni) | 9.0-11.0 |

| Tungsten (W) | 7.0-8.0 |

| Carbon (C) | 0.45-0.55 |

| Iron (Fe) | ≤3.0 |

| Property | Value |

|---|---|

| Tensile Strength | 1100-1300 MPa |

| Yield Strength | 800-900 MPa |

| Elongation | 10-15% |

| Hardness (HRC) | 38-42 |

Stellite31 Cobalt Alloy Rod resists acids like sulfuric and hydrochloric, and alkalis. It complies with environmental standards but may require specific disposal protocols due to cobalt content.

While robust, Stellite31 Cobalt Alloy Rod may face challenges:

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Urban) | <0.01 |

| Mild Chemical (pH 4-10) | <0.05 |

| Seawater | 0.02-0.03 |

Recommended welding methods for Stellite31 Cobalt Alloy Rod include:

Forming techniques: CNC machining, forging, and grinding. Use carbide tools for precision.

Stellite31 Cobalt Alloy Rod performed flawlessly in our turbine components. Exceptional durability!

John M.

Aerospace Engineer

Perfect for orthopedic implants. The cobalt chrome quality is unmatched.

Sarah L.

Medical Supplier

Reliable for valve stems. Great service from this China manufacturer.

Mike T.

Industrial Distributor

A: Stellite31 offers a unique balance of nickel and tungsten for enhanced heat resistance compared to standard cobalt alloys.

A: Aerospace, medical, oil & gas, and industrial manufacturing.

A: Yes, up to 1200°C, but prolonged exposure may reduce ductility.

A: Contact our sales team for current lead times based on order size.

A: Yes, but follow local regulations for cobalt disposal.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.

©2025 alloy-materials.com COPYRIGHT ALL RIGHT RESERVED.