Get in touch with us

Leave a message

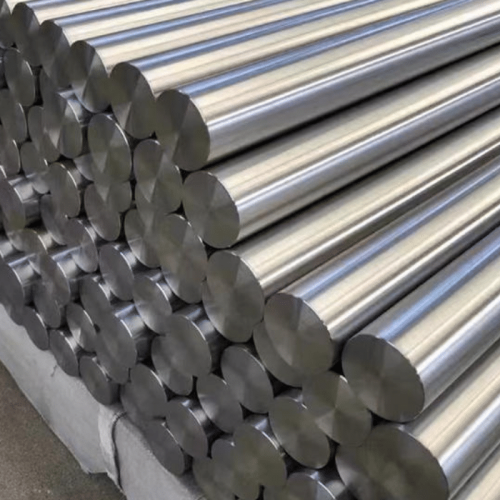

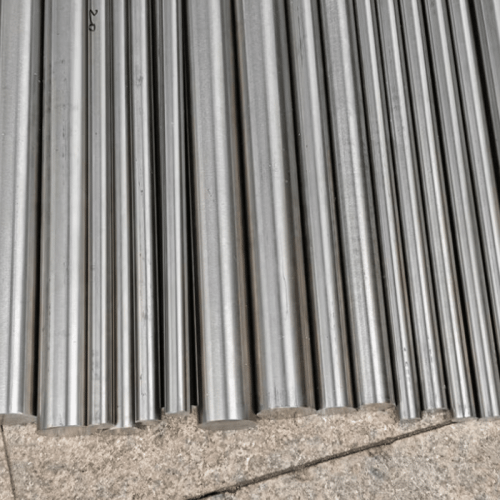

Stellite8 Cobalt Alloy Bar, a high-performance cobalt-based alloy, provides excellent wear resistance, corrosion resistance, and high-temperature stability. This cobalt chromium alloy is ideal for industries like aerospace, power generation, and chemical processing.

Contact our sales team for a quote on Stellite8 Cobalt Alloy Bar. Pricing varies based on specifications, quantity, and customization requirements.

Stellite8 Cobalt Alloy Bar serves industries requiring durable materials:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | Balance (50-55%) |

| Chromium (Cr) | 28-32% |

| Tungsten (W) | 8-10% |

| Carbon (C) | 1.1-1.7% |

| Nickel (Ni) | ≤3% |

| Iron (Fe) | ≤2% |

| Property | Value |

|---|---|

| Tensile Strength | 950 MPa |

| Yield Strength | 700 MPa |

| Elongation | 1-2% |

| Hardness (HRC) | 40-48 |

Stellite8 Cobalt Alloy Bar resists acids (e.g., sulfuric, hydrochloric) and alkalis effectively. It complies with environmental regulations like RoHS, ensuring safe use in restricted industries. Its cobalt base alloy structure ensures stability in corrosive conditions.

| Environment | Corrosion Resistance |

|---|---|

| Atmospheric (Air) | Excellent |

| Mild Chemical (Dilute Acids) | Very Good |

| Seawater | Good |

| High-Temperature Oxidation | Good |

Recommended welding methods for Stellite8 Cobalt Alloy Bar include TIG and plasma arc welding with cobalt-based fillers. Machining requires carbide tools due to hardness. Hot forging is viable, but cold working is limited due to moderate ductility.

Stellite8 Cobalt Alloy Bar is perfect for our aerospace components. Outstanding durability!

Susan K.

Aerospace Technician

Great corrosion resistance for chemical plant fittings. Highly reliable.

Nina L.

Chemical Engineer

Trusted China manufacturer. Stellite8 meets our high standards for quality.

Andy F.

Procurement Manager

A: Stellite8 has lower carbon content than Stellite20, offering better ductility but slightly less hardness.

A: Used in high-wear components, medical implants, and high-temperature applications.

A: Is it suitable for high-temperature environments?

Yes, up to 1000°C, but prolonged exposure may reduce performance.

A: Aerospace, power generation, chemical processing, medical, and automotive industries.

A: Requires TIG or plasma arc welding with cobalt-based fillers for best results.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.

©2025 alloy-materials.com COPYRIGHT ALL RIGHT RESERVED.