The stainless steel can’t be cut that simply without any concern. Some imagination is enough for this task. This cannot be done without using such tools and methods in practice, as well as knowing each aspect of that specific material. Whether you are a worker in a shop or a home canvas user, finding ways to reinforce high-quality cutting of stainless steel can carry a project through. This guide will highlight all the essential and pertinent ingredients and techniques that allow individuals to even alter their strategies for the better. This piece will review the factors that influence the selection of proper technologies and discuss some other key techniques related to the particular requirements of such a metal sheet with regard to its thickness. You shall easily comprehend stainless steel cutting when you learn that aspect today!

Introduction to Cutting Stainless Steel

Importance of Proper Techniques

It is highly pertinent to use certain techniques for cutting stainless steel so as to ensure accuracy, maintenance of the material quality, and general safety during the process. These metals are quite strong and resilient in most cases, within a range of 72 000 to 125 000 psi depending on the grade. Because of this, it avoids internal and external damages or corroding but most variations of steel offer difficulties when cutting without using the right technique.

These errors can result in rough cutting, irregularly shaped materials, and breakage of material. Taking an instance, using tools at the wrong speed and feed can cause overheating and consequently damage metals. Many studies report that precision increases considerably with minimum focus errors in laser precision and plasma cutting using 0.005 inches or less. In addition to that, the problems of the work surface and body tool, such as internal wear of the tool and surface wear of the material because of the tool, shall be avoided by cutting stainless steel with carbides or stones wherever possible.

Safety aspects are also a concern in this case. Working with stainless steel requires minimal cutting, as it creates heat buildup and sharp edges, which may injure or burn in case of hot material mishandling. This problem, however, can easily be solved with proper among others clamping technique as well as additional protective clothing. In conclusion, doing so not only quickens the process of doing the task, but it also improves the quality of what is done.

Challenges in Cutting Stainless Steel

There are several extrinsic and intrinsic factors that need to be considered prior to choosing the appropriate tool for cutting stainless steel. Going through the incredible stress of cutting stainless steel is one of the factors that makes the tools prone to wear out due to age, and require replacement faster in an operation. This is also one of the reasons why such an object is a poor conductor of heat – all the heat build-up remains confined to the area being cut and may result in warping or bending.

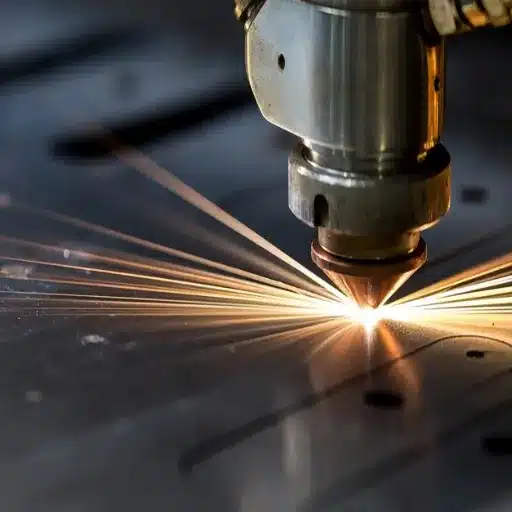

These are among the challenges that new cutting methods have come to solve. For example, laser cutting is known for its precision and well-defined edges. According to researchers, the laser cutting mechanism is able to maintain fabricating in a tolerance of ±0.005 inches and is cutting stainless steel of thicknesses of about ¾ of an inch. The only disadvantage of utilizing this technique is that it is very expensive to start using, and the experts who are involved only ensure that there is a suitable climate now.

Furthermore, there have been many advantages in the use of waterjet cutting, as it does not involve the operation of heat or the analysis of heat-affected components. Kolomenskyi et al (2013) even state that there exist sophisticated waterjets that penetrate stainless steel even at a thickness of the average 4-inches yet the edge remains as strong as that of a laser counterpart.

In rare circumstances where geodesic shapes need to be cut, the information is that one has to carve out geodes to the required size; this being most commonly the case, the present solution does not depart from using usual carbide-tipped steel cutters, whereas, where metal was desired to be cut on a smaller scale, a plasma cutter was found to be more efficient. However, it has been tried and established universally that when shorter and more thermodynamic methods of repairing and maintaining the tools are used, they last longer, including holding onto their sharpness. Such developments have been meant to demonstrate how cutting stainless steel, which has heretofore been one of the hardest things to do, has been made so much easier given the advancement in the area.

Essential Tools for Cutting Stainless Steel

Angle Grinders: Versatility and Power

Among all the primary methods used to cut stainless steel, one must also include steel cutting by compact and quite flexible, portable cutting machines. Also colloquially called angle cutters, they are usually fitted with a motor and a cutting disk that rotates at extremely high velocities and almost cuts through stainless steel panels, stainless pipes, and stainless rods. Today, there are a lot of different accessories available for angle grinders, such as cut-off wheels, lint discs, grinding discs, and many more.

During an industrial tools show in the year 2023, it was suggested that whenever relatively thicker stainless steel is to be used, it becomes relevant to make use of angle grinders having more than 1000 watts of power. Additionally, it would be of great help to possess angle grinders with a variable speed due to the fact that it will allow working on steel of various grades and thicknesses. In line with such a purpose, ergonomic handles as well as anti-kickback systems are quite practical, and thanks to this, they improve efficiency excessively even when performing very heavy duties.

The key issue is that stereotypically, both men and women alike do not merely purchase a disc without any attachment, but ensure they seek a type that shall help them cut efficiently and quickly. As expected, most of them opt for the 1.0 mm to 1.6 mm slim discs for cutting stainless steel, where accuracy is very important. On the contrary, for welding and grinding purposes, the best choice is machining-type cutting wheels rather than abrasive grinding wheels. The replacement of worn-down discs regularly is recommended for the order of more efficient work and extension of the service life of the angle grinder, which is why it is a very popular choice among competent professional radius mechanics and amateur home makers.

Circular Saws: Efficiency in Cutting

The existence of a circular saw for cutting stainless steel has proven to be very versatile, as perfect blade boards with the appropriate tools are available for almost everything out there, whether wood, metal, plastic, or even stone. An example of this can be seen, and most circular saws are trimmable. These saws are operated by an engine and spin the blades such that the saws remove material along the angular way as they lean against the blades. In the construction industry or in furniture design, sci-fi cutting or normal cutting can be achieved.

The modern-day circular blades introduced some modifications and development that are meant to make cutting rather much easier. This is also enhanced by a laser guide attached to the circular saw, several speed settings, and a fairly well-balanced circular saw in terms of the spread of weight. Assessing the different circular saw designs in the market also states that these days, brushless motors for such products are so far more common than before. It is because their power consumption is better and their service life surpasses that of the ordinary motors that have brushes. For example, it has been indicated that there is up to 30% advantage of this technology, which cuts down on expenditure and shortages of energy when operating the tools.

The influence of blade types to be used in circular saws, also referred to as saw types, is very significant. Carbide-tipped tooth blades, which assist in cutting hardwood, metal cases, and other durable materials, are more durable and last ten times that of the normal steel blades in assumption. Therefore, the best solution for heavy work, such as cutting stainless steel or tiles, is diamond-coated blades, as they cut without becoming dull.

This aspect of circular saw applications also remains a great concern. Built-in brakes, blade covers, a dust remover, and other equipment help achieve safety and ease of use. About such conclusions, it was established that one of the hypotheses in the use of portable motor-driven electric power saws in building construction works using a dust removal system, for instance, in industry, is that the amount of dust inhaled could be reduced by 90 percent.

Hand-held circular saws, in general, can be roughly divided into three camps according to the following considerations: blade size, cutting capacity, and power supply. Most of today’s hand-held circular saws are Lithium-ion compact saws in the cordless model, due to their lightweight and the fact that anyone can work for long durations due to the longer battery life. They are greatly valued by practitioners, especially in design, since there is no need to be fixed in a place.

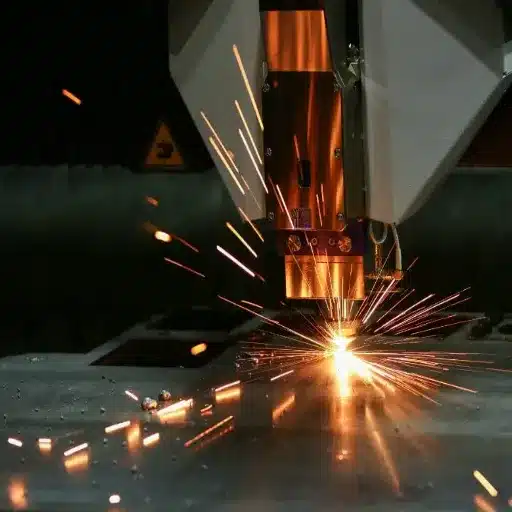

Plasma Cutters: Advanced Cutting Methods

In assignments related to rendering, most welders use the standard Plazcut machine. This is because the plasma cutter is the most effective tool when dealing with cutting stainless steel or any other commonly available form of sheet metal. Such a welder uses basic electrical energy and energy in the mechanical aspect after the analysis of the components on both hydraulic and pneumatic forces, which doubles the forces created by electricity or knives. But that could not be without the steel cutter for cutting steel sheets. It has been a game-changer for tens of years.

As per current statistics, it is foreseeable that the worldwide free-flowing electronics market will reach up to USD 2.97 billion in 2028. Such figures may be due to reliance on the above-sketched verticals evolving within the automotive, manufacturing, and construction industries. For instance, cutting stainless steel at high speeds is problem-free, where the Turbo and didactic machines come built with a speed range of 600 inches per minute (IPM) on different thicknesses, while also taking away the advantages needed, such as the ability to house a CNC or both a handheld and a CNC to ease out the different functions.

There is also an increase in the number of plasma cutting devices incorporating the inverter technology that assists users in making the equipment more compact and reduces electricity consumption. Indeed, modern plasma cutters can be carried around and utilised while on the move; however, this only goes as far as meeting the user’s professional standards. For instance, Powermax from HYPERTHERM and LTP from LOTOS are in high demand and well known for their durability, precision in cutting, and ease of use. Also, with the development of the so-called ‘SMART CUT ON’ feature, the cutters may reach the hands of amateurs, therefore decreasing render time as well as any preparatory processes for the task.

In selecting a plasma cutter, it is crucial to think about the power, the current (amperage), and the duty cycles, as well as the voltage needed, because this will be affected by the type of work to be carried out. These machines are built with very high technology, with different types of nozzles and curacoe parts for optimal operation and good service of the nozzle with these installations.

Choosing the Right Tool for Your Project

While looking for a specific tool in a specific project, one has to know the goals expected from that task and which appropriate tool, if any, is available. These days, it is known within the manufacturing sector that such tools as cuddy figurative studies in a project are different depending on several facts such as what tool to use for skimming and bilge water.

If what is needed is so basic, such as manipulating thin gauge metal not thicker than ¼, a torch withan ampere ranging from 20 to 40 can be used in these situations. However, if there is a need for people to cut really thick metal sheets for industrial use, only a 60 or above plasma cutter is necessary, as this makes it possible to cut even 1”+ thick metals. In these cases, models with adjustable amperage are more useful, as any thickness of any material can be cut without, for instance, cutting stainless steel into softer as well as harder, thicker materials.

The important thing to note is the duty cycle as well. For most plasma cutters used at a professional level, the duty cycle is at most 60%, which allows more working hours before getting hotter. However, it is also feasible to perform better using a low duty cycle (30%, 40%) in a homeowner’s or a do-it-yourself environment, since such devices are affordable.

The new generation cutters come with several improvements, such as the ability of the plasma torch pilot arcs, which allow cutting stainless steel even without cleaning the surface, to cut into the rust or the paint in the material. This reduces the time spent on cleaning and dressing of the workpieces, thus improving the productivity levels when it comes to maintenance and repair activities.

Another important feature that has been especially adopted in most of the plasma cutters is the power supply feature, where two input voltages of either 120V or 240V are applied because most work sites have different power supplies.

To sum up, the recent research strongly emphasizes the essence of purchasing the technology with easily replaceable parts since these are consumables widely available on the market. For example, high-quality nozzles, electrodes, or shields enhance reactivity in cutting stainless steel or any other material, besides the longer operational life of a tool’s consumables, which can be expensive in the long run. In addition, customers are advised to analyze the equipmentto determine whether it can complement or pair with the CNC (Computer Numerical Control) machines because precision and automation are necessary.

Through a careful examination and consideration of these factors, which are easily understood by both the user and keeping pace with both the advancement of the technology and the alterations in the performance benchmarks of the tools, the user will know without a shadow of doubt what tools are required for the project that they are undertaking.

Cutting Techniques for Different Thicknesses of Stainless Steel Sheet

Thin Stainless Steel Sheets

When cutting stainless steel sheets of a lighter gauge, laser or plasma is most preferable because it is able to cut cleanly and accurately with minimal tailing. Thin sheet materials are those that are not thicker than 0.125 of an inch (3.18 millimeters). Cutting these sheet materials using lasers is much simpler as they do not produce burrs, and they are more fitting within the given tolerances. For example, fiber lasers are known to be more efficient and accurate for cutting stainless steel.

In the last couple of years, however, with the advent of new technologies, laser cutting machines are able to cut at speeds not exceeding 1,000 IPM, particularly on thin materials, and this makes them applicable in most manufacturing operations where speed is a priority in addition to accuracy. Also, when nitrogen or oxygen red assist glass is used, lasers are used to neatly cut assigned faces without improving the discoloration and corrosion. This is extremely important because everything must look great at the end of the work, for instance, in the process of architectural production or when some decorated surfaces are produced.

Such cutters that effectively and affordably slice thinner metals at a decent speed are available today and are conventional plasma cutters. Where precision assumes a low priority in the list of requirements, where not everyone may be in a position to laser cut as per exact dimensions, plasma cutting (or plasma arc cutting as it is also referred to) serves the purpose. High precision plasma can cut up to 0.75 inches of thick materials by plasma cutting, and also, there is a possibility to go with this method for cutting thinner ones.

No special considerations are limiting the range of parameters; they may also be designed to cut any commercial glass, graze glass or flat glass, with or without the surface protective coat. Laser machines are suitable for cutting stainless steel over a wide range of thickness, given that stainless steel is a hard but ‘soft’ material.

In these contexts, these technologies are used for a more efficient and precise cutting of stainless steel metal sheets. This can be employed appropriately in improving the physics of the processes and techniques in question, depending on the given circumstances and capacity of the clientele.

Medium Thickness Sheets

However, from my own test cutting perspective, it is worth mentioning that medium gauge stainless steel sheet (0.750-2 inches) needs appropriate blades and gear so as to get its shape right. In general, a popular and economical solution for the sheet thickness is cutting stainless steel using a laser. According to recent studies, it is suggested that the cutting speed has increased by 40% compared to CO2 lasers when using a fiber laser. Thus, it is seen as a very efficient method.

Conversely, water jet cutting, which is based on the abrasive water jetting combined with tool action, allows cutting metal of any shape, due to the pressure flown waterjets. This method involves both water at high speeds mixed with a few metal powders, as well as other abrasives.

Interestingly, plasma cutters are still affordable and widespread ways of parting such thicknesses, particularly when dealing with high-definition, that is, high-precision technologies. Most recently, however, it has been shown that cutting stainless steel that has a one-inch thick wall and precise edges can be cut at 200 inches per minute with plasma technology.

To determine the appropriate cutting method for the moderate thickness of sheets, one should consider primarily the approach that works best based on the intended shape, the required edge finish, and the available resources.

Thick Stainless Steel Sheets

Cutting sheets of stainless steel with a thickness greater than 1 inch is usually referred to as “thick stainless steel,” and the technique would require the utilization of strong and hard-to-cut materials. Such precise methods also exist today, but even those that have been most effective so far are even more so with fiber laser cutting. It should be noted that in most cases, the amount of material that can be cut with lasers, as well as the torsional rigour of the cutting devices have been maximized in the last few years for the purpose of cutting thick metal. Designed for such purposes, modern laser fiber instruments can be operated to cut a stainless steel sheet of 1.15 inches thickness, at a speed of more than a hundred inches per minute, more or less exactly depending on the laser’s power and the like.

For that reason, oxy-fuel cutting may be regarded as just another ordinary system for thick stainless steels, especially when the thickness exceeds what laser and plasma cutting are designed to handle. Though slower, it is more effective for two inches or more of steel working, and it results in lower costs on simple tasks.

On the other hand, it must be noted that even a waterjet cutting stainless steel has a strategy for thick sheets, such that there will be no heat-affected zones, while the sophistication level achieved is almost perfect. When the pressure of the waterjets is over 60,000 psi, it is one of the methods used in cutting sandwich structures (rib zones) up to 3 inches thick in steel.

Ultimately, at the core of the matter is how best to cut stainless steel sheets of thick gages in a manner that all factors, i.e., thickness, speed of cut, cost, design intricacy, and so on, will be considered. Advanced systems, as well as organized operations, journey towards the achievement of the desired goals on those projects.

Pro Tips for Clean Cuts and Avoiding Damage

Avoiding Discoloration and Warping

For instance, cutting stainless steel, particularly in the laser machine or the plasma units, causes a color change in several factors. Some of the factors are exposure to very high temperatures or the use of cooling fluids. Optimum performance, however, can only be achieved if there is adequate preparation and modifications in the equipment. For instance, in cutting stainless steel, the sheet should be clean and free of any source of contamination before it is cut. Such measures are taken in order to prevent the excessive formation of colours after cutting. Moreover, the cutting machine must be set at its minimum power setting, as this will help in reducing the heat-affected zone, which otherwise leads to discoloration of the sheet metal.

A material can be cut using a waterjet, which sends out high-pressure water mixed with abrasive materials. This easily prevents any browning or heat effects on the stainless steel. In recent times, thermal injury caused by the use of water jet cutting machines has been reported to be almost negligible and is hence regarded as the most effective method of material removal from stainless steel without any form of deformation on the external covering.

In the cutting of stainless steel, for example, the cutting process can be nitrogen-enabled in order to cut without oxidation and damage to the chromium surface of the stainless steel. However, a study shows that there was an improvement in the post cutting-edge when nitrogen shielding was used in comparison to using oxygen shielding. It is, however, a little bit more costly to run and therefore adds some value, especially in cut or shaped designs, tailor-made jobs.

To limit excessive thermal increases, particularly as can be expected in an activity composed primarily of plasma cutters, better cooling systems, including and especially partial walls if required, and using gas/paper cooling enhancers can be brought into the picture. The strength of coatings works very well in these situations where all the essential parts of the particular workpiece to be cut are covered with reconstruction films, and hence those expensive paints stay away from any negatives.

Revamp could be most welcome to manufacturers who have issues with sharp cutting of some stainless steel cut images and fractures in general, making it possible that correct cutting materials are applied for the specific projects.

Techniques for Achieving Clean Edges in Metal Cutting

However, a smooth edge finish after the metal cutting is a very important quality, as well as efficiency, in manufacturing processes. The adoption of the latest cutting stainless steel technologies in place of the traditional methods, with particular emphasis on the combination of high precision laser cutting and plasma cutting stainless steel, has been known to give smoother, nearly burr-free finished edges. Within this context, CO2 and Fiber laser cutting machines, which offer ±0.001 inch precision, are ideal for cutting the very small and complex designs. Furthermore, accurately choosing the cutting angle and automated control also significantly helped in smoothing rough or jagged edges.

The incision speed of stainless steel is increased while in combination with these assist gases, such as nitrogen and/or oxygen, which also assist in the features of surface roughness in specific examples, as presented in the published literature. Stainless steel materials cutting in the presence of nitrogen can, on the other hand, attain more than 40 inches monthly in terms of process feed versus oxidation. Further, center lens power and height effects were induced and tested, which are known to be very important, especially for focused cuts of especially thin sections of steels or aluminum, or titanium, etc.

Moreover, today’s technologies are based on the usage of specific software and state-of-the-art physics that provide built-in CNC functionalities that support live processing. Sophisticated techniques also help in improving accuracy while cutting stainless steel, which considerably lessens the waste and increases production efficiency. Such concepts find the most elaborate expressions in the scopes of hardcore functionality and visual aesthetics.

Using Jigs and Guides for Precision

In the production process jibs assist in making, guides are significant components, and at the same time, fixtures are used to enhance accuracy, stability, or operation of machining and assembly. Through this mechanism, the dimensions and shapes of parts produced are the same or conform to a specific standard. Also, it has been said that using cut jigs may even increase output by 30% and that upfront cutting stainless steel configurations in using them severely reduces errors.

Due to the ability of jigs that adopt modular and changeable designs, their content is considerably enhanced. The techno elements distract the attention from the concepts and introduce a variety of factors based on the assistance provided by the gadgets installed in the cutting stainless steel machinery in droplets and air, which lowers the error percentage to 15%. These objectives are not only aimed at reducing these records but also at enhancing the performance of different industries, such as the aerospace and automobile industries, to name a few.

Reference Sources

1. Cutting Properties of Austenitic Stainless Steel Using AGF Laser Cutting

- Key Findings: This study investigates the cutting properties of austenitic stainless steel using a 2 kW CO2 laser. It highlights the precision and efficiency of laser cutting for stainless steel, emphasizing its suitability for industrial applications.

- Methodology: The research utilized AGF laser cutting techniques to analyze the impact of laser parameters on cutting quality and efficiency.

- Read the study here

2. Machining of Hard-to-Cut AISI 4462 Duplex Stainless Steel

- Key Findings: The study focuses on the machinability of AISI 4462 duplex stainless steel, using cutting speeds recommended by tool manufacturers. It provides insights into tool wear and cutting efficiency.

- Methodology: Experimental setups were conducted with varying cutting speeds and tool configurations to evaluate performance and durability.

- Access the paper here

3. AISI 304 Stainless Steel Milling Process State Diagnosing

- Key Findings: This research analyzes the milling process of AISI 304 stainless steel, focusing on cutting forces and torque to diagnose process states. It offers a framework for optimizing milling operations.

- Methodology: The study employed real-time monitoring of cutting forces and torque during milling to assess process stability and efficiency.

- Explore the article here

Frequently Asked Questions (FAQs)

How is the intricate cutting of stainless steel possible?

There are a few methodologies for cutting stainless steel with precision using the right cutting tools, enhanced with carbide tips on high speed blade or plasma cut tools. These lectures are simply ideal, since the lectures were designed in such a manner that it is possible to cut the hard material with almost no wear or any deformation. Furthermore, the problem of controlled cutting speed and feed rate, as well as overheating of the material, has to be addressed so that the machining process does not lead to warpingor dimensional inaccuracy.

What are the top techniques for reducing inaccuracies during machining?

Monitoring the cutting or machining process so that any corrections can be implemented instantly is one of the advanced techniques that help to minimize inaccuracy. These includes use of what is referred to as sensor-integrated guide systems. Moreover, sharp cutting tools are used, and the lubrication of the tools while machining ensures that the wear and tear of the tools is avoided, and there is no overheating when cutting stainless steel, which results in uneven cuts.

Are smart technologies efficient in the improvement of precision cutting of stainless steel?

Besides, the sensor-based systems, CNC machines, and all smart technologies on the market today facilitate improvement of precision cutting, and one of the ways in which this culture is through progress in technology. These technologies promote accuracy and enhance precision ways of cutting that come with their automatic controls, and allow for monitoring of the cutting activity so that the operator is able to avoid any misalignment of the cutting tool or positioning of the tool. This helps in reducing the errors and ensures consistent quality in even the most sophisticated forms of manufacturing.

Which instruments should you use for a close-fitting production?

Laser cutting, water jet cutting, and CNC machining – they are known as such operations as cutting stainless steel since they can cut the material to a specific size or dimensions. These special machines, which are specified for such elements as cutting of structural steel, where surveyed permissible dimension tolerance produced steel is used, are appliedwith alcohol antiseptics in all of the above machines. They include, if this is the case, most operations performed on such equipment, e.g., sharpening or replacing sharpening knives or blades, facings, or calibrations, would improve the efficiency of the device.

How can one machine stainless steel without lubrication?

It is possible to machine stainless steel without lubrication, though this is the least desirable option. This is because without a lubricant layer between the cutting tool and the workpiece, various friction forces are caused with the heat generated despite the worker’s aim within the target’s and workpiece’s proximity as well as the work tool. Furthermore, the time taken in cutting stainless steel without a lubricating substance is unnecessarily extensive since the cutting tools left out would not be used in the near future, thereby as well as no longer needed.

Which industry makes the most use of stainless steel machining in a sophisticated manner?

Aerospace, automobile, and even medical device industries had already developed the advanced expertise for complex pipe applications in cutting stainless steel. The efforts to construct precise parts and fittings pass the necessary safety and operational standards. These industries, on the other hand, incorporate more shoulder conditions for participation, called integration of more than one technology. As an illustration, within a factory, they use advanced sensor technology to use the sensing devices in the most efficient way possible while being the most precise in their use.