Different grades of galvanized plates are used widely across industries, but one such metal sheet, DX53D, is very popular for several reasons. DX53D is in demand globally. Where one is an engineer, learning the art of assemblies, construction, and other aspects requires an in-depth study of the materials available, such as the DX53D galvanized steel sheets.

There are a few possible reasons for this, and the regions of the DX53D have possible applications. Apart from its uses and advantages, implementing the material is equally interesting, and that is just what this text will allow you to do.

This article covers all aspects of the DX53D galvanized sheet and how it delivers practical benefits.

What is DX53D Galvanized Steel?

A type of steel sheet covered with a zinc layer for corrosion resistance falls under the DX53D galvanized sheet. It is exceptionally soft and non-alloyed steel, making it easy to form and reshape. The advantage of this coat is that it enhances the steel’s lifespan and creates an effective rust barrier in all weather conditions. Metals frequently associated with construction, automotive, and appliances often use DX53D because it works with all these industries to produce quality, durable goods.

Characteristics of DX53D Galvanized Steel

DX53D galvanized steel can be described as a highly formable, highly corrosion-resistant material. Some of its characteristics are listed herein:

- CHEMICAL COMPOSITION

DX53D steel usually contains carbon (C), manganese (Mn), and phosphorus (P), although at a very low content for high formability. The addition of the chemical thereby assists in creating a sufficient ductile and elastic profile, which is best for tough bending and shaping.

- C: max. 0.12%

- Mn: max. 0.6%

- P: max. 0.11%

- S: max. 0.045%

- MACHINING

DX53D has excellent extensibility and can be significantly bent before it breaks. This is useful in cases where deep drawing is required.

- Re: not less than 280 MPa

- Rm: not less than 270–410 MPa

- A8Down to Included90Up a from Factor: 26% on average for thickness)

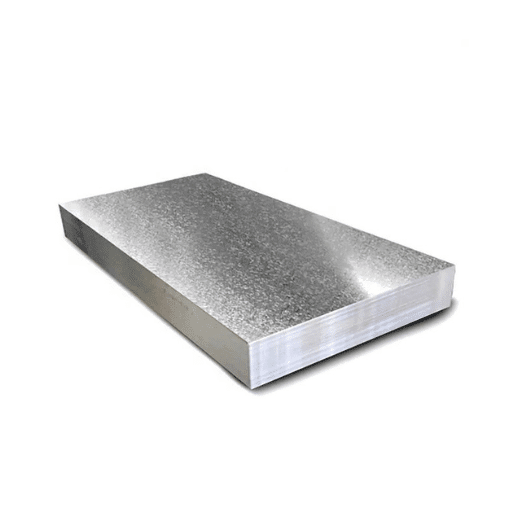

- Coating mass and thickness

In the case of coatings like zinc, the thickness is considerably greater and may reach Z600, while the protective layer varies from 100 to 600 grams per square meter. This layer provides a protective function for the base metal; therefore, the steel does not corrode over time.

- VISUAL APPEARANCE

The Available Finishes of DX53D Steel Alloy include minimised, normal, or after-treatment finishing to facilitate painting and enhance the aesthetic value further. This characteristic makes it workable for decorative as well as non-decorative purposes.

- USE CASES

- Buildings: Because of its anti-rusting and reinforcing properties, it is used in roof construction, walls, and structural elements.

- Vehicle: It is especially suitable for forming outer or inner panels, exhaust systems, or any other concrete and lightweight parts.

- Household: Prominently cast for washing machines, refrigerators & other household purposes.

Due to its high mechanical properties and excellent resistance to aggressive environments, DX53D galvanized sheet is characterized by its efficiency, safety, economy, and reliability for various industries. Due to the advanced manufacturing methods and strict quality standards, DX53D meets customers’ requirements.

Applications of DX53D Galvanized Steel

Dx53d galvanized sheet finds its application in a wide range of industrial sectors because it possesses remarkably high strength and resistance to rust and functional abilities, such as suppleness. Examples of such involve the following five case studies:

- Automotive Sector

In particular, Dx53d is primarily employed in manufacturing parts of vehicles attached to the body or for structural safety purposes. One of the main reasons for its considerable usage is that Dx53d components can be stretched onto complex surface forms, and an extra thickness of zinc lining on the surface shields the car from corrosion and severe weather conditions.

- Technical Solutions in the Construction Industry

It is mostly used to make walls, roofs, and frameworks for buildings. Considering its capacity to resist degradation, this material is perfect for external and industrial purposes and will last a very long time.

- White Goods

Specific DX53D galvanized steel is used, in particular, for several white goods such as washing machines, refrigerators, cookers, and other kitchen accessories. The materials used are to look good and last for high-end finishes and payload-bearing bodies; thus, there is fineness in craftsmanship during manufacture.

- Air Conditioning Equipment’s Construction

Construction of air conditioning systems must include warming up, ventilation, and cooling. Steel elements are used in ducts and insulation materials that are supposed to be corrosion-proof and easy to fabricate.

- Electric Systems

DX53D is made of various cases and panels for electrical systems. The material, being corrosion-free, aids the protection of electrical systems and provides far better functioning even under excessive working circumstances.

Advantages of Using DX53D in the Automotive Industry

| Key Advantage | Description |

|---|---|

| Excellent Formability | Ideal for deep drawing and complex shapes. |

| Corrosion Resistance | Long-lasting protection against rust. |

| Lightweight | Reduces vehicle weight for better efficiency. |

| Cost-Effective | Affordable compared to alternative materials. |

| High Ductility | Suitable for bending and stamping processes. |

| Durable Coating | Zinc layer ensures extended service life. |

| Customizable Dimensions | Available in various sizes and thicknesses. |

| Eco-Friendly | Recyclable material, reducing waste. |

| Enhanced Surface Quality | Smooth finish for aesthetic applications. |

| Compliance with Standards | Meets ISO, ASTM, and EN specifications. |

How is Galvanized Steel Coil Produced?

The protection of steel against corrosion using zinc coating is derived through a metal process that brings about the development of the DX53D galvanized sheet. Such a process consists of the following steps:

- Surface preparation.

This is done on steel before galvanizing, i.e., removing any dirt, grease, or other foreign materials.

- Annealing.

Before coating, cleaned steel is first annealed to enhance its ductility.

- Coating of zinc. This is done continuously, where the steel panel emerges and is coated with zinc.

- The final processes.

The coating applications are provided ready to use, and the zinc coat undergoes polymerization during the drying process.

The process particularly aids in the hardening and corrosion-proofing of steel, making it applicable in the industries.

Advantages of the Hot-Dip Galvanizing Process

Hot-dip galvanization provides excellent corrosion protection that lasts, is accompanied by minimal maintenance and cost, and is therefore a perfect alternative for industries and structures.

Understanding Zinc Coating on Steel Coils

Steel coils with zinc coating are generally used to prevent steel from rusting and to increase their service life. The process of galvanizing involves immersing steel coils in a bath of hot liquid zinc. That way, the zinc penetrates into the steel and bonds with it at the molecular level, producing shaped layers of zinc and iron dissolved in one another and a coat of pure zinc on the surface.

Advantages of Coatings Made of Zinc

- Protection against Corrosion

The metal zinc provides a barrier layer against environmental factors, preventing contact with the steel surfaces. It, however, depends on the environment. In rural areas, it will take over 50 years or so, whereas in urban or maybe coastal areas, it will take up to 25 years before the galvanized steel coating is done.

- Healing Capabilities

The great thing about zinc coatings is that they can “self-repair” themselves, and this feature is extended to repairs of small nicks and damages. As the already existing coating is broken, the zinc oxidizes and combines with the water to form a zinc carbonate that protects the steel.

- Economical Nature

Galvanized steel is considered to be very economical compared to other methods of corrosion resistance. According to World Steel, galvanization is approximately 20-30% cheaper than some alternatives throughout the product’s useful life.

- Range of Applications

Industries such as construction, automotive, and appliances will find zinc-coated steel coils useful. Their widespread use can be attributed to their resistance to the sun and other elements, such as rain, that wear and tear rooftops, air conditioning units, and exterior covers are made of.

Most Accepted Zinc Coating Norms

Zinc coatings are ranked based on either thickness or weight, which is generally given in grams per square meter (g/m²).

Some of the standards include:

- Z100 (100 g/m²): Lightweight, for interior use mainly.

- Z275 (275 g/m²): The most common type taken in construction, which is heavyweight.

- Z450 (450 g/m²): Extra weight where heavy coating is needed.

Stringent standards, such as ASTM A653 and ISO 1461, ensure that quality and safety requirements are met for zinc-coated steel products.

The combination of zinc as a corrosion-proof coating and steel as a strong base makes zinc-coated steel coils the ultimate material for such valuable and durable constructions. Improvements in each of these fields will bring gains in efficiency and changes in the scope of work.

Quality Control in Galvanized Steel Coil Production

| Quality Control Aspect | Key Parameters |

|---|---|

| Surface Quality | Check for rust, cracks, and uniform coating. |

| Coating Thickness | Measure using magnetic or eddy current tools. |

| Adhesion Strength | Perform cross-hatch, bend, or peel tests. |

| Corrosion Resistance | Conduct salt spray or environmental tests. |

| Dimensional Accuracy | Verify thickness, width, and length. |

| Hardness Testing | Use Rockwell or Vickers hardness methods. |

| Zinc Coating Weight | Ensure compliance with ASTM or ISO standards. |

| Uniformity of Coating | Inspect visually or with specialized tools. |

| Microscopic Examination | Analyze the cross-section for defects. |

| Process Parameters | Control galvanizing speed and temperature. |

Why Choose DX53D Galvanized Steel Sheet for Your Project?

In projects where durability, corrosion resistance, and versatility are considered vital, the DX53D galvanized sheet is the way to go. Zinc helps prevent steel from corrosion; thus, it will save your structure from rust, whether indoors or outdoors. Strong, easy-to-fold materials ensure structural rigidity while working on them. Moreover, this material adheres to international quick lime standards that ensure constant quality and reliability in its performance in various applications, such as construction or the automotive industry.

Excellent Corrosion Resistance Properties

The DX53D is a corrosion-resistant material ideal when moisture, chemicals, or extreme weather conditions are anticipated. The material in discussion has a metallic zinc layer, which offers corrosion-resistant qualities because it is a hot-dipped galvanized steel, and thus it will resist further corrosion damage. Available sources indicate that the lifetimes of steel pieces after galvanizing can last fifty or more years, depending on the environment.

The thickness of such a zinc layer is generally in the range of 5μ to 15μm. This is adequate even for highly industrial or marine areas that tend to be highly corrosive. Moreover, experimental studies indicate that the galvanized steel does not corrode even after a considerable time in the salt spray. It withstands hundreds of hours of salt spray test and exhibits extraordinary resistance even in adverse conditions.

Unlike bare steel, DX53D galvanized sheet requires little maintenance, which reduces liability even further since fewer repairs or replacements are required over the life cycle. Advances in the implementation of industry standards such as EN 10346 ensure that the quality and performance metrics of DX53D–which boasts corrosion resistance—are compliant and among the highest in the industry.

Formability and Mechanical Properties

Many industries like DX53D due to its excellent workability, mechanical attributes, and all. Here are five main mechanical properties of DX53D that stand out:

- High Levels of Ductile Strength

DX53D’s ductility is said to be excellent, second to none, and it can undergo highly complex forming processes without weakening its structure. Surely, it is very, very good for deep draw forming.

- Bearing the Yield Strain

Generally, this type of sheet metal grade ranges from 140-300 MPa in yield stress level, meaning that it will undergo stress without an action of strain.

- Good or High Tensile Stress

This is because this material is covered in a 270-500 MPa tensile range, which ensures excessive force will not tear DX53D sheets apart and softens them when pulled.

- Break Occurs at a High Elongation

DX53D has extremely high elongation, with values notably higher than 22% on specific thicknesses, showing that it can take a lot of stretching before tearing it apart.

- Thickness Control in the Process of Manufacturing

Through EN 10346 standards, thickness tolerances are met precisely, which leads to a processed and manufactured product with minimum variation in quality.

Applications in the Construction Industry

A DX53D galvanized sheet is commonly found in construction, thanks to its excellent engineering and mechanical properties. Let’s put it this way, I would rather consider it for its tough use in encapsulation of ceilings and wall finishing, including framing, than for its dual use due to its characteristic high wear and abrasion resistance. The material minimises thickness tolerances and maintains high standards in its quality which makes it suitable horny for construction projects.

Comparing Galvanized Steel Plate to Other Materials

The structural benefits of galvanized plates are evident, given the repeated service rendered by this material. It is important to note that steel plate, which is produced by welding or fitting, is subject to corrosion. In the latter case, the DX53D galvanized sheet is suitable due to the zinc level, the presence of pigmentation, sacrificial coating in the primer coat, and top coats as the final finishing. Responding to aluminum, which is light and more fragile, this particular steel can undertake the function of a heavier section that can withstand higher loads. In addition, it is cheaper than stainless steel and offers sufficient corrosion resistance provided the constructional or industrial activities are such to require these properties.

DX53D Steel vs. Standard Galvanized Steel

| Parameter | DX53D Steel | Standard Galvanized Steel |

|---|---|---|

| Formability | Excellent for deep drawing | Limited for complex shapes |

| Corrosion Resistance | High due to zinc coating | Moderate, depends on coating thickness |

| Tensile Strength | 270-380 MPa | Varies, typically lower |

| Yield Strength | 140-260 MPa | Varies, typically higher |

| Ductility | High, suitable for intricate designs | Moderate |

| Applications | Automotive, appliances, construction | General construction, basic applications |

| Surface Quality | Smooth, suitable for painting | May have imperfections |

| Coating Options | Multiple (Z, ZA, ZF, etc.) | Limited |

| Cost | Higher due to specialized properties | Lower, more economical |

| Standards | EN 10346, ASTM A653 | ASTM A653, ISO 1461 |

Benefits Over Carbon Steel and Stainless Steel Pipe

| Parameter | Galvanized Steel Pipe | Carbon Steel Pipe | Stainless Steel Pipe |

|---|---|---|---|

| Corrosion Resistance | High due to zinc coating | Low, prone to rust | Excellent, resistant to most environments |

| Cost | Moderate, economical | Low, cheapest option | High, expensive material |

| Strength | Moderate, suitable for low-pressure uses | High, ideal for high-pressure systems | High, suitable for structural applications |

| Durability | Long-lasting in humid environments | Shorter lifespan without coating | Long-lasting, even in harsh conditions |

| Ease of Fabrication | Easy to weld and shape | Easy to fabricate | Requires specialized welding techniques |

| Aesthetic Appeal | Moderate, zinc coating adds shine | Low, plain appearance | High, polished and attractive |

| Applications | Plumbing, fire systems, outdoor structures | High-pressure pipelines, structural uses | Corrosive environments, decorative uses |

| Maintenance | Low, requires minimal upkeep | High, prone to rust and wear | Low, resistant to wear and tear |

| Weight | Moderate, lighter than stainless steel | Moderate | Heavier due to alloy composition |

| Environmental Suitability | Ideal for humid and mild corrosive areas | Limited to non-corrosive environments | Suitable for extreme conditions |

Understanding the Mechanical Properties of DX53D Galvanized Steel Sheet

DX53D galvanized sheet can be used in various forming processes due to its unique mechanical properties of strength and enhanced tolerance to stretching. This makes it easy to work with as even after work hardening, elongation and tensile strength values remain adequate to achieve further shaping or bending without a high risk of cracking. In addition to that, it enhances durability in aggressive media due to the amount of deposited zinc on its outward surface. Therefore, such properties of these materials favor use in applications that aim at achieving toughness, flexibility, and adequate protection against wear and abrasion.

Impact of Zinc on Steel Grade and Formability

| Parameter | Impact of Zinc |

|---|---|

| Corrosion Resistance | Enhances protection against rust and oxidation. |

| Formability | Improves ductility for complex shapes. |

| Strength | Maintains strength while adding durability. |

| Surface Quality | Provides smooth, uniform coating. |

| Weldability | Requires careful handling to avoid defects. |

| Microstructure | Refines grain size, improving toughness. |

| Coating Thickness | Directly affects durability and lifespan. |

| Environmental Suitability | Ideal for humid and corrosive environments. |

| Cost Efficiency | Reduces maintenance and replacement costs. |

| Applications | Widely used in automotive and construction. |

Suitability for Deep Drawing and Home Appliance Manufacturing

The flexibility of DX53D steel in terms of deformation is used in making significant draw components, where it finds application for its ability to deform without failing by tearing or fracturing. Centered around the low carbon amount in DX53D, the steel is provided with high deformability, which is reached step by step during manufacturing details with high accuracy and complexity by several operations.

This steel, with its advanced allowable characteristics, in conjunction with zinc, is very efficient in the manufacture of waterproof tanks for tents, refrigerators, washing machines, rotisseries, or heaters. This zinc forms a layer around it, preventing corrosion attack and weathering, which doubles the shelf life of the appliances without distorting their shiny appearance.

The authors report that this technological progress also allowed the date of manufacture of a DX53D yield point to range between 140-300 MPa and the elongation range to be between 22 and 38%, depending on other factors. Now, due to these characteristics, it is possible to reach improved designs without destroying the structure of the manufactured product. Therefore, DX53D finds wide use in manufacturing household appliances as well as fine parts of the automobile industry that need deep-drawn formation.

Furthermore, due to innovation in business processes such as automatic presses and better lubrication, Dx53d Galvanized Sheet is now even more widely utilized in drawing processes. It guarantees a constant high standard and the mass manufacture of a more detailed and effective solution.

References

- Statistical research of steel grades: DX51D, DX52D, and DX53D – This article discusses the mechanical properties of DX53D and related steel grades.

- Reducing the melting and sublimation of the galvanized sheets – Focuses on the interaction of DX53D steel with laser beam cutting.

- The Role of Al-10%Si Coating in the Manufacture and Use – Discusses the requirements and properties of DX53D steel flat products for cold forming.

Frequently Asked Questions (FAQ)

Q: What is DX53D Galvanized Steel Sheet?

A: DX53D galvanized steel sheet is a type of hot-dip galvanized steel widely used in various applications due to its excellent formability and corrosion resistance. It is commonly used in the steel industry for making body panels, household appliances, and other metal products.

Q: How does the hot dip process work for galvanizing steel sheets?

A: The hot dip process involves immersing the steel sheet in a bath of molten zinc. This results in a galvanized layer that is highly corrosion resistant, protecting the steel’s surface from rust and other forms of deterioration.

Q: What are the benefits of using galvanized sheets?

A: Galvanized sheets offer enhanced durability, corrosion resistance, and longevity. The galvanized layer protects against environmental elements, making it ideal for outdoor structures, roofs, and various steel structures.

Q: How does DX53D differ from other galvanized steel sheets like DX51D?

A: While both DX53D and DX51D are types of hot-dipped galvanized steel, DX53D offers better formability, making it suitable for more complex shapes and applications. Both are commonly used in the steel industry, but the choice depends on the project’s specific requirements.

Q: What standards apply to galvanized steel sheets like DX53D?

A: Galvanized steel sheets like DX53D must adhere to standards such as ASTM and JIS, which ensure the quality, thickness, and properties of the galvanized layer, ensuring its suitability for various applications.

Q: What is zero-spangle galvanized steel?

A: Zero-spangle galvanized steel refers to galvanized sheets with a smooth and uniform surface finish. The absence of spangle is achieved by controlling the cooling rate and zinc chemistry during the hot dip process, making it desirable for applications requiring a clean appearance.

Q: Can galvanized sheets be used for corrugated sheets and plates?

A: Because of their strength and corrosion resistance, galvanized sheets are often used to manufacture corrugated sheets and plates. These are widely used in roofs and as cladding materials in construction.

Q: Are there different types of galvanized sheets available?

A: Yes, there are different types of galvanized sheets available, including hot-dip galvanized steel, electro-galvanized steel, and zero-spangle galvanized steel. Each type offers different surface finishes and properties, catering to specific needs in construction and manufacturing.

Q: What are some applications of DX53D galvanized sheets in everyday products?

A: DX53D galvanized sheets are used in various applications, including body panels for vehicles, household appliances like washing machines and refrigerators, and various steel structures. Their flexibility and durability make them ideal for these uses.