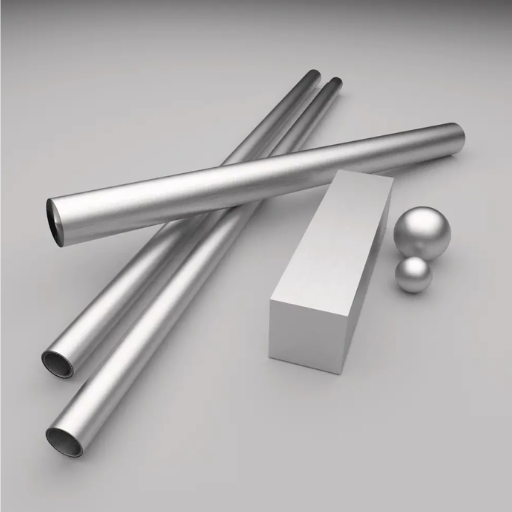

Ferritic stainless steel is a notable type of stainless steel because of its distinct properties and its usefulness across many sectors. This guide seeks to elaborate on the ferritic stainless steel by dividing it into three major components: grades, properties, and applications. In understanding its grades, we obtain a broad understanding of some types and their distinguishing features. The properties section will encompass other attributes of the steel, such as mechanical, physical aspects, like, for example, corrosion resistance and thermal conductivity. This will, finally, help us build the applications section where we will demonstrate the range and scope of industries like automotive, construction, and appliances that widely utilize ferritic stainless steel. This ought to serve both the professionals in the field as well as anyone with a general interest, providing crucial information on how important these steels are in the modern world.

What is Ferritic Stainless Steel?

Ferritic stainless steel contains iron and chromium as its main alloying elements, and has little to no nickel content. It is known for good thermal conductivity in addition to its excellent corrosion resistance and its magnetic properties. This steel type has a body-centered cubic (BCC) crystal structure, which, along with the capability to endure oxidation, makes it suitable for use in a range of applications requiring resistance to stress corrosion. It is employed in situations where the optimum combination of cost, strength, and corrosion-resistant properties is needed.

Understanding Ferritic Stainless Steel

Stainless steels, such as ferritic stainless steel, are unique due to their high resistance to corrosion, which is primarily attributable to the chromium content. Moreover, its thermal conductivity and magnetic properties distinguish it from other types of stainless steel. Ferritic stainless steel is ideal in cost-sensitive applications because of the automotive parts, industrial equipment, and kitchen utensils that demand enhanced strength and resistance to corrosion.

Properties of Ferritic Stainless Steel

- Corrosion Resistance: The stainless steel of ferritic type is well-known for its superiority with respect to corrosion in mainly non-chloride low stress settings. So, its use can be made in areas where there is possible contact with water or mild chemicals.

- Thermal Conductivity: It possesses better thermal conductivity when compared with austenitic types of stainless steel which is beneficial in applications related to the exchange of heat.

- Mechanical Strength: The ferritic type of stainless steel possesses reasonable values of tensile strength around 400-600 MPa while offering moderate elasticity and good ductility.

- Magnetic Properties: This type of material has magnetic character due to the ferritic system that dominates its crystal structure, which has some advantages in making responsive components to magnets.

- Oxidation Resistance: Ferritic stainless steels are notably resistant to high temperature oxidation and are useful in components like automotive exhaust systems. Depending on the type of alloy added, they can work well at up to 750°C.

- Cost Effectiveness: Ferritic grades unlike austenitic grades are low in nickel and therefore more cost effective and within budget while still retaining strength.

With such characteristics together with the body centered cubic (BCC) structure making up the stainless steel, helps in different sectors of industries.

How Does it Differ from Other Types of Stainless Steel?

Like austenitic and martensitic stainless steel, Ferritic stainless steel has its differences ,which are attributed to its composition and microstructure:

- Microstructure: Ferritic stainless steels possess a body centered cubic (BCC) crystal structure, while austenitic stainless steels have face centered cubic (FCC) structures. This also affects their magnetic properties, work-hardening capabilities, and limits the extent of work hardening.

- Nickel Content: Contrary to austenitic stainless steel with 8-10% or greater contained nickel, ferritic stainless steel has little to no nickel content which makes it less susceptible to market changes based on nickel supply and price.

- Corrosion Resistance: Although ferritic stainless steel possesses resistance against chloride stress corrosion cracking and oxidation, in most cases, its resistance in chloride-rich environments is lower than austenitic grades, especially those with molybdenum like Type 316, which decreases it in comparison to ferritic grades.

- Mechanical Properties:

- Compared to austenitic grades, ferritic stainless steel is noted to have higher ductility and toughness, especially at lower temperatures.

- A specific alloy will yield tensile strength values of 380-600 MPa.

- Depending on the grade and application, yield strength falls within 205-450 MPa.

- Thermal Conductivity and Expansion

- Compared to austenitic stainless steel, ferritic stainless steel possesses a greater degree of thermal conductivity and a lower threshold for thermal expansion, thus making it more suitable for use in heat exchangers and the automotive industry for exhaust systems.

- Weldability

- Due to lack of ductility and higher susceptibility to grain growth or brittleness in the heat-affected zones, ferritic grades are less weldable than austenitic grades. Sophisticated methods, such as preheating the welding area and post weld heat treatment, can enhance welds.

These features enable ferritic stainless steels to withstand high temperatures while enabling austenitic grades to dominate in highly corrosive or high-impact environments.

Why is Ferritic Stainless Steel Magnetic?

Ferritic stainless steel possesses magnetic properties because of its atomic structure’s Basis on Body Centered Cubic (BCC) crystal lattice. which is ferromagnetic. This configuration permits the alignment of the iron atoms to magnetic fields. This is in contrast with austenitic stainless steels, which have a face-centered cubic (FCC) structure and hence, can’t exhibit magnetic properties. The addition of chromium in ferritic stainless steels increases the corrosion resistance while maintaining the original magnetic characteristics of the steel.

Exploring Magnetic Properties

The body-centered cubic (BCC) crystal structure of ferritic stainless steels enables the magnetic domains within the material to align, producing unique magnetic properties unlike any other. Unlike them, austenitic stainless steels possess a face-centered cubic (FCC) structure, which renders them non-magnetic, thus making them vastly different. The composition of a ferritic stainless steel, how it has been processed, and the thermal treatments done greatly influence its magnetic behavior.

Key Technical Parameters Influencing Magnetic Properties:

- Crystallographic Structure:

Ferritic stainless steels retain their magnetic BCC structure. Examples include grades such as 409, 430, and 439.

2. Composition:

Typically, the amount of chromium in ferritic stainless steels ranges from 10.5% to 30%, increasing magnetism but also improving corrosion resistance.

If nickel is present, it has to be in limited amounts to retain magnetic properties.

- Permeability:

Relative magnetic permeability (µr) is largely increased for ferritic stainless steels where it is close to 500 to 600 while being annealed.

- Hysteresis Losses:

Due to optimal composition and fewer impurities, they possess lower bound hysteresis losses compared to carbon steels.

- Resistivity:

They also possess lower electric resistivity and higher electrical resistivity, decreasing eddy current losses in comparison to regular carbon steel.

The materials described above are utilized in applications where corrosion resistance and magnetic response are required, including electromagnetic shields, solenoids, and transformer cores. It is important to know the interrelationship between composition and processing to develop their functional magnetic properties for certain applications.

Compared with Austenitic Stainless Steels

While looking at stainless steel types, a comparison and contrast series of austenitic and ferritic is particularly intriguing due to its differences in specifics like properties, applications, etc. The ferritic stainless steel should perform best in electromagnetic applications due to the ferrite dominating crystal structure, giving better magnetic properties. However, in harsh environments, austenitic stainless steel will outperform them in almost every form of corrosion due to being non-magnetic. Furthermore, austenitic steels are preferred for most complex fabrications because of their ductility and weldability stemming from a higher composition of nickel and chrome. Both types contain valuable assets that can be put to use based on what the application calls for.

The Role of Chromium Content

Chromium is central to improving the corrosion issues faced by stainless steels. I think its most important purpose is to act as a barrier by oxidizing and stopping primary oxidation and, therefore, further degradation of the material. Typically, at least 10.5% chromium is present in stainless steels, as this is the minimum quantitative value for effective chromic passivation. Stainless steels with even greater amounts of chromium, of the order of 16 to 18%, are better able to resist corrosion, especially in more aggressive environments. For these reasons, chromium becomes an important consideration in the material selection for constructions subjected to moisture, chemicals, and extreme conditions. Besides, the greater amount of chromium also increases the hardness and resistance to scaling at elevated temperatures, which increases the flexibility of this element in metallurgical design.

How Does Ferritic Stainless Steel Resist Corrosion?

Ferritic stainless steels have high amounts of chromium, enabling it to passively resist oxidation. This passive layer reduces the amount of oxygen reaching the underlying metal, which minimizes oxidation and corrosion. Apart from this, ferritic stainless steel does not have nickel in appreciable quantities, making these materials immune to stress corrosion cracking and suitable for use in regions with differing temperatures and humidity.

Corrosion Resistance Mechanisms

Stainless ferritic steels resist corrosion mainly due to the presence of a passive oxide layer, which is created by chromium in the stainless steel. This layer starts forming when the chromium value increases past the threshold of roughly 11-12%. It builds a strong wall that stops oxygen and water from being in contact with the steel. Some of the important parameters to consider while measuring the resistance towards corrosion are:

- Chromium: is measured in the range 12-30% and is important for the metal to be able to increase its protective oxide layer.

- Molybdenum Content: This level is only applied for some grades of metals. This level can go up to 2.5% in order to increase the resistance towards pitting and crevice corrosion, especially in areas with high levels of chlorides.

- Grain size: This has an inverse relation to the size of grains. Smaller grain sizes improve the shielding layer, which passes through the layer.

- Working temperature: It is favorable to temperatures up to 750°F (400 °C) for most ferritic grades before the risk of scaling increases.

- Geographic Parameters: Performs well in environments with moderate to high levels of humidity, provided chloride exposure is limited.

Due to the absence of nickel, the chances of stress corrosion cracking are lower. Therefore, ferritic stainless steels can be utilized for the construction of components like vehicle exhaust parts, industrial devices, and parts of building.

Comparison with Other Stainless Steel Grades

Ferritic stainless steels are distinguished by their relatively low cost and exceptional resistance to stress corrosion cracking due to their low nickel content. Ferritic steels tend to have better thermal conductivity and resistance to chloride cracking compared to austenitic grades, but may lack the impact toughness and weldability of austenitic grades at lower temperatures. In comparison to martensitic stainless steels, ferritic grades offer better resistance to corrosion and retaining ductility, whereas martensitic steels are superior in strength and hardness, and therefore, more suitable to use in demanding applications.

Duplex stainless steels which incorporate features of both austenitic and ferritic grades are believed to be stronger and more resistant to corrosion than ferritic steels, especially in very hostile conditions. They may, however, be more difficult to manufacture and cost more. In the end, the selection of a stainless steel grade is determined by the combination of the particular use, environmental conditions, and mechanical requirements.

Factors Affecting Corrosion Resistance

Steels are passive oxide cradle protectors that lower resistance towards corrosion while aiding because the level of constituents, mainly alloys, increases, like chromium, for example. The ranges of nickel and molybdenum aid in the better enhancement of passive cradle formers, also known as oxides. Additional factors, such as environmental aspects, play a significant role,like emergency exposure, along with temperatures as well. For commencing, pitting or grooved erosion can result from chloride ions, while in marine surroundings or in chemical processes. With proper maintenance, like not exposing steel to corrosive agents and regular cleaning, the life strength of the steel.

What are the Mechanical Properties of Ferritic Stainless Steel?

Mechanical properties of ferritic stainless steels include excellent high strength, good ductility, and great resistance to stress corrosion cracking. These steels usually have good toughness; however, their impact strength is somewhat lower than that of austenitic grades, especially at low temperatures. Ferritic stainless steels also have moderate weldability and are commonly used in applications requiring rigidity and structural integrity. The balance of mechanical strength and corrosion resistance makes these steels suitable for automotive parts, industrial equipment, and architectural structures.

Strength and Ductility in Ferritic Grades

In my research, I can tell that the brittleness and flexibility of ferritic stainless steels are balanced with a focus on strength. These grades have good tensile strength with moderate elongation, making them dependable under loads but undesirable for distortion. The addition of some alloying elements ,such as titanium or niobium, might improve some of these properties, but in general, ferritic steels remain less ductile. The main advantage of ferritic steels is their corrosion resistance and ability to endure in lower stress environments.

Performance at High Temperatures

Based on my research, ferritic steels work at moderate efficieny at elevated temperatures relative to other steels, like austenitic steels, due to having a lower resistance to creep. While the strength and oxidative capabilities are preserved under some conditions, with time there is loss of stability which limits useful applications to moderately high temperature environments. The thermal characteristics can be improved somewhat with alloying or grain refinement, but these characteristics make the steel more suited where resistance to higher temperatures isn’t a major requirement.

Impact of Low Carbon Content

A low carbon content in steels greatly affects their properties, such as weldability, toughness, and corrosion resistance. Steels with a low carbon content, usually under 0.25%, show better weldability because the lower carbon content decreases the chances of carbide precipitation during welding. Precipitating carbides during welding can cause cracking, which lower carbon makes significantly less damaging. Furthermore, lowering carbon content improves toughness by reducing the formation of brittle martensite during heat treatment.

From a corrosion resistance perspective, lower carbon steels are also less likely to suffer from intergranular corrosion. This is especially true for stainless steels which prefer having a carbon content less than 0.03% such as 304L and 316L grade to avoid chromium carbide precipitation at the grain boundaries. However, having low carbon and corrosive elements results in the material losing strength and hardness. To counter this without ruining other properties, alloying elements like manganese, chromium, or nickel would need to be added.

Parameters To Be Observed:

- Carbon content: Generally lower than 0.25% and ultra-low grades at approximately 0.03% for use in corrosion-resistant applications.

- Weldability Threshold: Carbon Equivalent CE ≤ 0.40%.

- Impact Toughness: Structural steels should have values greater than 27 J of Charpy V-notch impact energy at low temperatures, which is -20 degrees Celsius or below.

- Hardness Range: Typically ≤200 HB for low carbon steels to retain machinability and ductility.

Optimize balance between strength, durability, and resistance properties with appropriate application based alloying, heat treatments, or deles.

Which Applications are Best for Ferritic Stainless Steel?

Ferritic stainless steels have a wider industry application due to their ability to withstand corrosion along with good thermal conductivity, while possessing low to moderate strength, unlike other ferrous materials. These include automotive parts like exhaust systems, kitchen and home appliances, architectural trims, and heat exchangers. Apart from these, they are ideal for industrial and some marine equipment as they endure exposure to chlorides or mildly reactive chemicals. Also, their resistance to stress corrosion cracking, along with good high-temperature properties, renders them useful in power generation and furnace components.

Industrial and Commercial Uses

I depend on stainless steel alloys for their strength and durability, as these materials are highly adaptable. These alloys, for example, are critical in the automotive industry for the manufacture of exhaust systems that need to endure high temperatures while being corrosion resistant. I also appreciate their use in food and beverage as kitchen equipment and storage appliances because of their non-reactive and sanitary properties. Their performance in mildly aggressive chemical environments also makes them invaluable in industrial machinery and chemical processing plants.

Advantages in Specific Applications

For example, I greatly appreciate stainless steel due to its extremely corrosion-resistant properties. This attribute alone makes them reliable in damp environments as well as chemically infused ones. Their great structural stability also goes a long way for people in industries like manufacturing and construction, which is why they value stainless steel. Alongside all of these properties, their low maintenance tasks required make them appealing while considering sustainability in practice.

Limitations and Considerations

Although these materials possess various advantages, there are notable downsides and considerations to take into account. First, the production costs associated with these materials could be higher relative to others, which could impact lower-cost projects. Second, their performance may fluctuate with extreme temperatures, where thermal expansion or brittleness may be problematic. For example, some alloys may have significant compositional and structural alterations above 400°F (204°C).

Moreover, while these materials are highly resistant to corrosion, they can also be vulnerable to some chemical environments, like particular concentrations of acids or alkalis. The negative effects of these materials’ incompatibility with intended applications make their evaluation pivotal before use. Finally, more precise and intricate methods of fabrication, like welding or machining, may require additional tools and skill, thus increasing costs.

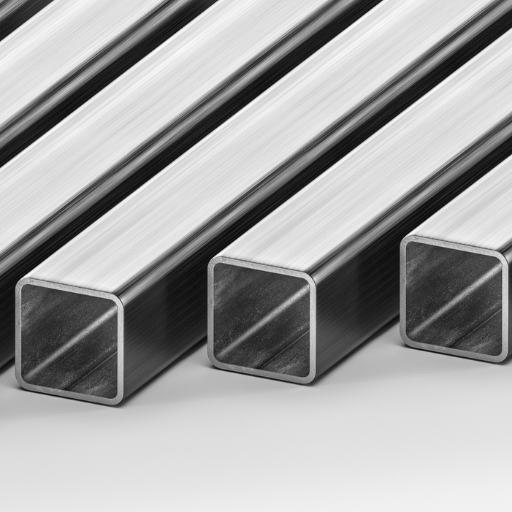

What are the Popular Grades of Ferritic Stainless Steel?

Like all other stainless steels, ferritics may be subdivided into several commonly used grades, each possessing unique characteristics meant for particular applications. Some of the more common ones are:

- 430 – Often used in kitchen equipment, this grade is noted for good corrosion resistance as well as formability suitable for use in automobile trims.

- 409 – This grade is commonly utilized for vehicle exhaust systems owing to its high resistance to high-temperature oxidation.

- 439 – Used in automotive and industrial applications, it is preferred because of its better corrosion resistance compared to 409.

- 444 – This grade is especially useful for water heaters and heat exchangers, having superior corrosion resistance, particularly in chloride containing tissues.

These grades offer a good balance between cost, adequate resistance to oxidation, and thermal transmission, which makes them adaptable for many industries.

Detailed Overview of Ferritic Stainless Steel Grades

Ferritic stainless steels represent a class of iron alloys where chromium serves as the primary alloying element. Such steels are easily fabricated and exhibit good thermal conductivity while being reasonably priced. Below is a succinct review of the most common grades compiled from the best available information.

- 409

- Composition: 10.5-11.75 % Chromium, maximum 0.08% Carbon, and trace amounts of Nickel.

- Properties:

- Possesses reasonable oxidation resistance upwards to 675°F (357°C) during continuous usage.

- Economical and widely utilized in various industries.

- Applications: Suitable for use in automotive exhaust systems, mufflers, and catalysts owing to their heat and corrosion resistance.

- 430

- Composition: 16-18 % Chromium, Carbon 0.12 % max.

- Properties:

- Moderate resistance to corrosion in mildly aggressive environments.

- Good formability and thermal conductivity.

- Applications: Made for kitchen utensils, tabletop appliances, and for ornamental trim/molding of buildings, therefore highly used in household items.

- 444

- Composition: 17-19 % Chromium, 1.75-2.50 % Molybdenum, Carbon < 0.025%.

- Properties:

- Very high resistance to pitting and crevice attack, particularly with chloride-bearing water.

- Very good scaling resistance to 1000°F (537°C).

- Applications: Commonly used but not limited to water heaters, heat exchangers, and solar panels, where durability is required and aggressive environments need to be resisted.

These ferritic stainless steel grades are notable for their economic and performance balance, with particular industrial and domestic uses in mind. They show considerable resistance to oxidation, scaling, and mild corrosive environments, making them vital components in various industries.

Spotlight on Grade 430

Ferritic stainless steel Grade 430 is one of the most commonly used alloys of stainless steel due to its cost-effectiveness and significant resistance to corrosion. Ferritic Grade 430 contains 16-18% of chromium with very little nickel, which makes it affordable while still maintaining some of its performance characteristics.

Key Technical Parameters:

- Cr Content: 16-18%, enabling better oxidation and mild corrosion resistance.

- Density: Near 7.7g/cm³, common density among stainless steels.

- Tensile Strength: Between 450-600 MPa, Strength sufficient for multiple applications.

- Hardness (Brinell): approximately 150 HB, allows workability along with adequate strength.

- Max Service Temp: Close to 815°C (1500°F) grade shows reliability at higher temperatures.

Applications:

With its commercially attractive features, Grade 430 is used widely in kitchen appliances, automotive trims and architectural fittings. Its aesthetics along with low thermal expansion allow it to be used in decorative purposes. Also, it is used for pipings and equipment for chemical processing due to its resistance to nitric acid.

The alloy’s combination of technical properties along with commercial perspectives make grade 430 attractive for both household and industrial applications.

Comparison with Other Steel Grades

Grade 430 stainless steel stands out as one of the more cost-effective options due to its ferritic structure when compared to other grades, including Grade 304 and Grade 316. While Grades 304 and 316 are austenitic and more costly due to their superior corrosion resistance, Grade 430 offers greater environmental value at a lower cost without sufficient resistance. Unlike austenitic grades, however, it does lack some strength as well as weldability. For instance, Grade 316 is a popular choice for marine applications due to the additional molybdenum grafted in, which protects against chloride corrosion. Grade 430, however, cannot compete with this. On the contrary, concerning Grade 410, Grade 430 shows better levels of corrosion resistance alongside lower hardenability, making it appropriate for decorative and household uses. As a whole, Grade 430 is better suited for cost-sensitive noncritical applications.

References

- A Comprehensive Guide to Ferritic Stainless Steel Grades

- What are Ferritic Steels? Properties, Applications, Grades and More

- Ferritic Stainless Steel Properties and Applications

Frequently Asked Questions (FAQ)

Q: What is ferritic steel?

A: Ferritic steel is a type of stainless steel characterized by its body-centered cubic crystal structure. It typically contains iron and chromium, with little to no nickel, making it magnetic and resistant to stress corrosion cracking. It is often used in applications requiring good corrosion resistance and high-temperature oxidation resistance.

Q: What are common ferritic steel grades?

A: Common ferritic steel grades include 409, 430, and 439. These grades offer good corrosion resistance, formability, and are often used in automotive exhaust systems, industrial equipment, and kitchenware. Each grade of stainless steel in the ferritic category has specific properties suited for different applications.

Q: How does ferritic stainless steel differ from austenitic grades?

A: The primary difference between ferritic and austenitic stainless steels lies in their crystal structure and composition. Ferritic steels have a body-centered cubic structure, while austenitic grades have a face-centered cubic structure. Ferritic steels are magnetic and contain higher chromium content, whereas austenitic grades typically contain nickel, making them non-magnetic and more ductile.

Q: What are the applications of ferritic stainless steel alloys?

A: Ferritic stainless steel alloys are commonly used in automotive exhaust systems, architectural applications, and industrial equipment. They are favored for their resistance to corrosion and oxidation at high temperatures. Additionally, they are used in kitchen utensils and appliances because of their magnetic properties.

Q: Are ferritic steels considered magnetic stainless?

A: Yes, ferritic steels are considered magnetic stainless steels. Their body-centered cubic structure allows them to be inherently magnetic, unlike austenitic grades which are non-magnetic due to their face-centered cubic structure.

Q: What is the role of the British Stainless Steel Association in the context of ferritic steels?

A: The British Stainless Steel Association provides guidance and information on various forms of stainless steel, including ferritic steels. They help in promoting best practices, offering technical support, and disseminating knowledge on different grades of steel, ensuring quality and standards in the industry.

Q: How do ferritic steel grades compare to carbon steel?

A: Ferritic steel grades typically offer better corrosion resistance and oxidation resistance compared to carbon steel, due to their chromium content. However, carbon steel is generally stronger and more durable under mechanical stress. The choice between the two depends on the specific requirements of the application, such as environment and temperature conditions.

Q: What are group 2 ferritic steels?

A: Group 2 ferritic steels are a classification within ferritic steels that have higher chromium content, typically around 17-30%. These types of ferritic stainless steel are used for applications requiring enhanced corrosion resistance and are often found in chemical processing and power generation industries.

Q: Can ferritic stainless steel be used as an alternative to martensitic stainless steels?

A: Ferritic stainless steel can be used as an alternative in applications where high strength is not the prime requirement. While martensitic stainless steels are known for their hardness and strength, ferritic steels offer better corrosion resistance and are more cost-effective for applications like automotive parts and kitchen equipment.