If we were to compare tool steel grades, CPM T15 would be one of the better classes for optimal tool performance. This is because CPM T 15 is regarded as an Oriental-style steel that possesses all the necessary properties to deliver edge retention. However, what are the specific details that distinguish it from other steels? How does the CPM T15 apply in terms of dual function mordant, sharpening, and damaging?

Everything about the CPM T15 is laid out for a better understanding of what it is composed of, what it is suitable for, and the role that this grade plays in the fabrication of blades and tools. Knives only begin to scratch the surface of steel and its adoration by many. Savvy? This piece is all about providing that information: science, performance, and practical function – content about CPM T15 present in this given material.

Introduction to Knife Steel

The steel used for making knives is their backbone and key to life, edges, and functional usage of the knives. Basically, knife steel is an alloy, mainly consisting of iron with carbon and other elements as well, such as chromium, vanadium, or molybdenum in order to acquire specific strength. However, the steel quality is also dependent on its ability to optimize these key features, such as edge retention, corrosion resistance, toughness, and ease of sharpening. Additionally, every steel type is categorized for specific purposes and applications; therefore, selecting the type of steel is crucial in associating the knife with its intended function.

What is Knife Steel?

The steel used to manufacture knives is quite different, as its composition is designed to enhance wear resistance, hardness, and sharpness for efficient cutting or performance.

Importance of Steel Composition

The composition of blade steel is crucial for its performance and suitability in a given application. Any alloy comprises several elements, each providing specific properties of the knife, such as strength, sharpness, or other functional characteristics. The following are the main elements that are found in most knife steels and the impact they have:

- Carbon (C): Carbon is one of the most critical components in the equation when it comes to knife steel, and it influences the hardness as well as edge holding ability. While high-carbon steel indeed boasts serious levels of sharpness, it is more prone to rust if appropriate measures for preservation are overlooked.

- Chromium (Cr): This specific element is necessary for rust prevention purposes, and thus, it falls under the category of stainless steel. The steel is regarded as stainless provided it contains more than 13 percent. As a result, metals in this group exhibit enhanced resistance to rusting and discoloration.

- Vanadium (V): This is one of those elements found in almost every high-grade CPM T15 steel, where it enhances the performance of wear-resistance characteristics. The same contribution is extended towards imparting a desired fine-grained structure and consequent enhanced strength.

- Molybdenum (Mo): This component helps improve the corrosion resistance and toughness at elevated temperatures, making the steel suitable for adverse working conditions

- Cobalt (Co): Primarily, it is used to make the steel harder and stronger. Furthermore, it enhances the efficiency of certain alloying elements.

Take a look at the comparison table of prominent knife steels and their features:

| Steel Type | Carbon (%) | Chromium (%) | Hardness (HRC) | Key Features |

|---|---|---|---|---|

| 1095 Carbon Steel | 0.95 | 0.4 | 55–58 | High toughness, easy to sharpen, prone to rust |

| AUS-8 | 0.7–0.75 | 14 | 58–60 | Good corrosion resistance, balanced performance |

| S30V | 1.45 | 14 | 58–61 | Excellent edge retention, moderate toughness |

| VG-10 | 1 | 15 | 60–62 | High corrosion resistance, very sharp edge |

| M390 | 1.9 | 20 | 60–62 | Superior edge retention, outstanding toughness |

Knowing the ingredients helps experts and amateurs decide on the appropriate steel for knives and other cutlery, which can range from survival knives used outdoors to kitchen cutlery or knives for specific, specialized cutting purposes. As metallurgy advances and steel production technology improves, newer grades are further developed, pushing the limits and enhancing the performance of knives by the grade CPM T15 ratio.

Overview of High Vanadium Steels

High, or enhanced, vanadium steels are well recognized for their characteristics, such as wear resistance, maintaining sharpness, and damage resistance. Vanadium addition more prominently aids in attaining the desired fine-grain structure, being better suited for forming more complex vanadium carbides within metals. Attaining these attributes from high-vanadium steels makes them exceptionally desirable for scenarios where even sharp cutting surfaces, once established, must pass various operational tests while being exposed to adverse environmental conditions. This article lists five examples of such high-vanadium steels. Their details and respective grad cpm t15 are also discussed below:

| Steel Type | Vanadium (%) | Carbon (%) | Hardness (HRC) | Key Features |

|---|---|---|---|---|

| CPM S90V | 9.0 | 2.3 | 58–61 | Exceptional edge retention, corrosion resistance, very wear resistant |

| CPM S110V | 9.0 | 2.8 | 59–62 | Premium wear resistance, superior edge retention, good toughness |

| CPM-10V | 10.0 | 2.45 | 60–63 | Extremely high wear resistance, excellent edge life, moderate corrosion resistance |

| Vanadis 4 Extra | 4.0 | 1.4 | 60–64 | Good toughness, high wear resistance, reliable in demanding conditions |

| CPM S30V | 4.0 | 1.45 | 58–61 | Balanced performance, excellent edge retention, corrosion resistant |

The availability of a variety of these steels makes them a favorite for cutting and machining applications, ensuring both professionals and everyday DIY enthusiasts can get precisely what they want from their particular job. The remarkable properties of high-vanadium steels, enhanced by advanced metallurgy, take durability and performance to an entirely new level once more.

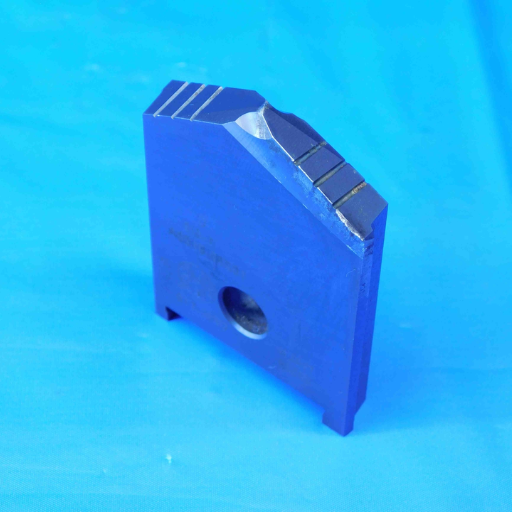

Exploring Grad CPM T15

CPM T15 is an alloy that provides excellent durability for cutting tools. Grad CPM T15 is described as a high-speed steel alloy for use in extremely harsh environments where wear and tear are excessive. Tungsten carbides naturally have a greater ability to maintain their integrity, even at high temperatures, when subjected to external forces that would otherwise cause deformation and breakage. This is suitable for applications that include problems associated with machining hard, difficult-to-grind materials. Most importantly, the prominence of hardness will preserve the sharpness of the cutting blades for a long time, and the more complex the surface.

Properties of grad cpm t15

- Excessive Amount of Tungsten

Tungsten serves to significantly protect against wear and tear, which prolongs the tool’s life in the majority of cases.

- Vanadium Additive: From the point of view of strength

From the point of view of strength, vanadium enhances the impact performance of the steel and also promotes resistance to chipping and cracking under heavy loads in impact applications.

- Long Lasting

The Grad CPM T15 keeps blades sharp for an unusually long period, which is beneficial in the making of specific tools that require a certain level of sharpness.

- Very Hard

Rockwell levels measure up to about 67 HRC; thus, they can endure harsh environments without fracturing.

- High Temperature Operating Conditions

Redness is not a problem, as the steel exhibits good red hardness, making it strong enough to cut at higher levels in shifting.

Comparative Analysis with CPM Rex 76

| Parameter | CPM T15 | CPM Rex 76 |

|---|---|---|

| Hardness (HRC) | Up to 67 | 68-70 |

| Edge Retention | Very high | High |

| Toughness | Moderate | Moderate |

| Wear Resistance | Excellent | Excellent |

| Corrosion Resistance | Low | Low |

| Ease of Sharpening | Difficult | Difficult |

| Primary Use | Precision cutting tools | High-speed tools, industrial cutting |

| Carbide Content | High vanadium carbides | High vanadium and tungsten carbides |

| Heat Resistance | Excellent | Excellent |

| Applications | Abrasive material cutting | Heavy-duty tasks, machining |

Applications of T15 Tool Steel

T15 tool steel is well known for possessing an excellent blend of hardness, toughness and red hardness and, therefore, is highly appropriate for some very challenging industrial applications. Here are five essential applications of the T15 tool steel:

- High Cutting Tools

T15 is extensively used in the fabrication of cutting tools, including drills, taps, end mills, and reamers. With its extreme hardness and wear resistance, its tools can last long even in high-speed metal cutting conditions.

- Punching and Deep Drawing Tools

T15, due to its stable dimensions under long-term use conditions, is widely used in the manufacture of punches and dies, which require precision and, in the process, durability at high pressures.

- Cutting Tools

The broaching applications that involve T15 steel necessitate that the tools be cast in steel that withstands increased stresses without deforming or losing the cutting edges.

- Tools for Shaping

Grad cpm t15 possesses high tensile strength and hardness, which can withstand harsh conditions, making it ideal for use as forming tools in applications such as extrusion, which require a material resistant to both wear and temperature.

- Milling Inserts

Often, T-15 is used in the manufacture of such milling tools. They enable the processing of hard materials without compromising their cutting capability, even at high operating temperatures, ensuring optimal tool performance.

CPM and Its Significance

CPM steels refer to Crucible Particle Metallurgy (CPM) type steels, which are known for their high performance and are produced using a complex process that involves atomizing the steel. This process is used to form steel powder with wonderful particles during cooling and then solidify them together due to various reasons, such as good toughness, a homogeneous structure, and high wear resistance.

What is CPM Steel?

Through the unique process of Crucible Particle Metallurgy (CPM), Carbon (or crucial) steel has been created through several process steps, such as converting the original grade CPM T15 High-Speed into molten fine particles of steel and then fusing the same, which provides the advantages of increased durability and improvement in properties of high wear resistance.

Benefits of CPM in Knife Making

| Key Point | Benefit |

|---|---|

| Carbide Distribution | Uniform carbides improve wear resistance |

| Edge Retention | Exceptional sharpness retention |

| Toughness | High toughness reduces chipping |

| Wear Resistance | Superior resistance to abrasion |

| Hardness | Achieves high hardness levels |

| Corrosion Resistance | Enhanced in stainless CPM steels |

| Heat Resistance | Performs well under high temperatures |

| Durability | Long-lasting performance in tough tasks |

| Precision | Fine microstructure allows detailed shaping |

| Versatility | Suitable for various knife applications |

How CPM Enhances Edge Holding

The introduction of CMP steel has fundamentally advanced edge retention in knife making by achieving better carbide dispersion as well as improved wear resistance. Traditional steel-making processes often have certain inherent limitations, including the risk of contamination and the control of grain growth. However, powder metallurgy has addressed these issues by producing steels with a homogeneous internal structure. Due to this composition, the ability of a given steel to stay sharp over time without breaking is enhanced.

Statistics show that CPM steel knives, such as CPM T15 or CPM S30V, can offer an increased edge retention of 30-40% compared to similar knives produced using standard techniques. CPM steel has smaller and more densely packed carbides, which harden the steel and minimize its tendency to deform or lose sharpness.

Another noteworthy attribute of CPM steel is its enhanced ability to maintain both toughness and hardness. This trait helps reduce edge chipping tendencies observed in most ultra-hard steels, thereby enhancing the productive life of the blade. Whether it’s cutting chores, culinary tasks, or survival, this enhanced grad CPM T15 performs cutting abilities with excellent sharpness and strength in blades, ensuring its frequent and prolonged use by most users who are knife enthusiasts and craftsmen alike.

Spyderco and T15 Steel

| Key Point | Details |

|---|---|

| Steel Type | CPM T15 |

| Manufacturer | Crucible Industries |

| Hardness (HRC) | Up to 68 |

| Edge Retention | Excellent due to vanadium carbides |

| Wear Resistance | High, suitable for abrasive tasks |

| Toughness | Moderate, balances hardness and durability |

| Corrosion Resistance | Low, not stainless |

| Ease of Sharpening | Challenging, requires diamond stones |

| Primary Use | Precision cutting, industrial tools |

| Spyderco Application | Used in Mule Team knives |

| Performance | Retains sharpness under heavy use |

Spyderco’s Knife Offerings with T15

Ever since its establishment, Spyderco has earned respect within professional circles for crafting high-quality blades and continues to impress its collectors with advancements in steel hardness and resistance. In this regard, Spyderco adds T15 steel, the most wear-resistant steel variant, thanks to its dense tungsten and high cobalt content in the composition, to its range. A perfect example of this is the T15 steel-treated series of knives, built for long periods of cutting tough materials without stress, as they neither bend nor break easily.

One example of a Spyderco that utilizes T15 steel is a knife designed in conjunction with a custom knife maker, intended to survive an outdoor environment or a concentration camp, where the blade might need to cut through tough materials. In particular, they are ideal for fieldwork that involves continuous wear and tear. T15 steel edges also retain their sharpness longer than many of the exotic, expensive steels available, a feature enhanced by the excellent tests conducted on CATRA testing, which led to the results for this steel.

Performance Review of Spyderco Knives

Generally, Spyderco’s knives that contain T15 steel are usually easier to use compared to most. Regarding Grade CPM T15 knives, their edges do last quite a while, as evidenced by the excellent results obtained from a standard test on their knives, as stated above. Furthermore, as mentioned earlier, these knives are designed in such a way that, regardless of the copies or forgeries thrown at them, they perform decently; therefore, these knives and/or the Korean War Chosons are also very useful in camping and budget applications.

Why Choose Spyderco for T15 Steel Knives?

Spyderco knives have built a reputation for themselves based on exceptional craftsmanship and state-of-the-art materials, making them perfect for individuals who appreciate excellence in tools, whether for personal or professional use. More importantly, here are five comprehensive justifications as to why choosing Spyderco T15 steel knives is the best options available:

- Excellent Surface Hardness and Sharpness

The incredible hardness in T15 steel will make sure that the blade stays very sharp for a long time. Additionally, Spyderco’s heat treatment cycle is specifically tailored for maximum effectiveness. Various CATRA test results show that Spyderco Grad CPM T15 knives stay sharp for longer than knives from the competition, which makes them suitable for intense use.

- Outstanding Cut and Abrasion Properties

Generally, the T15 steel Spyderco knives in particular are fantastic in terms of detail, cutting, and brushing qualities because they do not get easily blunted even amid aggressive use. This feature comes in handy when cutting through items like ropes, wood, or man-made textiles, among other materials, especially during rapid work.

- Flawless Design as Well as Comfortable Management of The Instrument.

Every G10 t15 follows the core design philosophy of Spyderco, which is to make products as ergonomically convenient as possible. With this approach to knife making, connecting the T15 blades with properly developed handles elevates the experience of cutting to the next level.

- Non-corrosive Feature, Made Available Through Protective Coat

Well, in the case of T15 steel, and as a result, sharpness isn’t achieved; usually, one has to put up with carbides, which have low corrosion resistance. To solve the problem, Spyderco manufactures blades that have durable anti-corrosion coatings. This provides a shield that prevents the blade from coming into contact with the atmosphere immediately and losing its qualities.

- Already Put to the Test

Overall, any user of Spyderco’s products will have no reservations about the knives or equipment for outdoor activities, survival, or similar purposes. This is all because the high-performance T15 steel, with an impeccable track record in the field, and the quality that Spyderco products are known for, make these knives “mission critical”.

Conclusion

Knives are quite famous among outdoor enthusiasts, and one of the most popular ones is the Spyderco, featuring CPM T15 blades, which offer supreme levels of durability, the ability to cut for a long time without blunting, and good resistance to abuse. Due to the factors mentioned above, the popularity of these knives is increasing in the market every day as more people opt for knives designed to perform in harsh environments, particularly those involved in sharp blade activities.

Summary of Key Insights

- Superior Edge Holding

Among the many characteristics that make T15 steel very versatile and durable is its high tungsten addition. Available metallurgical studies indicate that T15 contains 18% tungsten, resulting in an extreme hardness of 67 HRC. Hence, It is needless to say that it is ideal for multi-purpose cutting workshops.

- Better Wear Resistance

Reinforcements in the form of molybdenum and vanadium not only enhance the strength of T15 steel but also significantly reinforce its abrasion resistance. Results from tests suggest that T15 steel is more resistant than many conventional tool steels, and this is a crucial quality, particularly in extreme conditions where service longevity is a concern.

- Dependability in Extreme Environments

Spyderco produces a range of knives with T15-grade steel, the quality of which matches the innovation of their designs. Such Spyderco knife brands are practically used and tested in extreme conditions, including extreme cold, heat, and wetness, to assess their performance. Most reviewers have had good experiences with these knives in the extremes of wet forest areas, akin weather, and dry barren areas.

- Application Simulation

The Spyderco blades, made of T15 high-grade steel, are suitable for a wide range of uses, from basic survival to intricate cutting tasks. This is because the shape and materials of these blades lend themselves to general tough challenges, without compromising the ability to handle intricacies.

- Reviews Approved and Reports of Short Supplies

Grad CPM T15 steels are gaining increasing interest for several reasons. Once Spyderco knives made using these materials are sold over the internet, it is rare for a person to criticize their performance, as most people who purchase and use them appreciate and acclaim the knives for their cutting capabilities and durability.

The reports that present this particular data on sales trends show an increasing interest in knives made from high-grade materials, such as T15.

If the advanced properties of steel, creative design, and consistent performance, which surpass the demand for usefulness, are sufficient justifications, the Spyderco knives grade CPM T15 become a very high-level product both to experts and laymen alike.

Future of Knife Steel Innovations

In the future, the knife steel industry is expected to evolve due to advancements in materials and technologies, driven by the increasing expectations for performance and durability. Several changes are taking place in the world of knife steels. The following is a list of the top five innovations identified.

- Ultra High Carbon Steels

The steels are being developed with a higher percentage of Carbon content to address the challenges of achieving hardness while retaining an edge. For instance, prototype blades with a carbon content above 2% displayed excellent results in tests of resistance to deformation.

- Powder Metallurgy (PM) Steels

Powder metallurgy methods are increasingly being used as they produce steel with a finer stress-free texture. CPM S45VN steel, a popular example of PM steel, has been improved by 20% in terms of toughness and corrosion resistance compared to previous grades.

- Nitrogenated Alloys

Innovations sparked the high-strength new species of nitrogen-bearing steels, namely, LC200N, also known as tertiary nitrogen, and H1. The remarkable resistance against corrosion of stainless steels has an upper limit and thus, the use of marine climates and other elevated humidity forces them is seen.

- Cryogenis Improvements in the Field of Precipitation-Oriented Ferrous Materials

The use of deeper cryogenic treatment depths is being investigated to develop an improved micro-grain structure in steel, thereby enhancing toughness and increasing edge retention by 15% in treated blades.

- Steels of New Generations and One Step Towards Recycled Ones

There is a new trend of innovations that focus on sustainability, allow the consistency of knife steels, but have their source in recycled materials. These alloys retain the properties of traditional high-performance alloys while meeting the growing demand for such products.

Such innovations aim to create advanced cutting steel, ensuring that knives of the future will not only be instruments but also precise, high-efficiency elements that can be used in various cases.

Final Thoughts on grad cpm t15

I am of the view that grad cpm t15 is a modified tool steel since it offers exceptional mechanical properties and longevity. The steel’s extreme wear resistance, due to its heightened tungsten content, makes it suitable for complex tasks, while its hardness also extends its life even in those harsh conditions. Generally, it is what I would refer to as a premium-quality product, particularly for those who value the performance and accuracy of the equipment.

References

- CPM Assessment Knowledge Assessment for Management Skills Based on AMA Book of Knowledge

- This source discusses CPM (Critical Path Method) in the context of management skills and graduate programs.

- Access the source here

- Teaching Critical Chain Project Management: The Academic Debate and Illustrative Examples

- This article examines teaching resources and academic debates surrounding CPM and project management, with relevance to business and graduate studies.

- Access the source here

- Efficient Project Management Schedule for MSc Studies in Northwestern Nigerian Universities Employing CPM and PERT Techniques

- This research focuses on CPM techniques applied to graduate-level project management schedules, providing academic insights.

- Access the source here

Frequently Asked Questions (FAQ)

What is CPM T15 steel and its properties?

CPM T15 is a high-speed tool steel known for its excellent wear resistance and high hardness. It is primarily composed of tungsten and molybdenum, which contribute to its ability to maintain a sharp edge under high temperatures. The powder metallurgy process used in its production allows for a fine microstructure that enhances its toughness and edge stability.

How does CPM T15 compare to other high-speed steels?

When compared to other high-speed steels like M4 or S30V, CPM T15 offers superior wear resistance due to its high tungsten content. This steel is particularly favored in applications where edge retention is critical, making it a popular choice among knife enthusiasts. Its hardening capabilities also allow it to achieve high hardness levels, often reaching HRC 60 or above.

What are the heat treatment requirements for CPM T15?

CPM T15 requires precise heat treatment to optimize its properties. The typical process involves quenching in oil or water to harden the steel, followed by tempering at a controlled temperature range. This treatment enhances its toughness while maintaining high wear resistance, making it suitable for demanding applications like knife blades.

Is CPM T15 suitable for kitchen knives?

While CPM T15 is primarily used for industrial applications and high-performance knives, it can be suitable for kitchen knives if the user prioritizes edge retention and wear resistance. However, its hardness can make it more challenging to sharpen compared to lower hardness steels, which may be preferred for kitchen use.

What are the benefits of using powder metallurgy in CPM T15 production?

The powder metallurgy process used in the production of CPM T15 enables better control over the steel’s microstructure, resulting in enhanced properties such as toughness and wear resistance. This method also reduces the size and distribution of carbides, enhancing overall performance compared to traditional steel development techniques.

Can CPM T15 be used in high-temperature applications?

Yes, CPM T15 is suitable for high-temperature applications due to its high-speed steel characteristics. Its ability to retain hardness and wear resistance at elevated temperatures makes it a viable option for tools and blades used in environments where heat is a factor.

What is the significance of tungsten and molybdenum in CPM T15?

Tungsten and molybdenum are critical elements in CPM T15 that contribute to its high wear resistance and hardness. Tungsten enhances the steel’s ability to withstand high temperatures, while molybdenum improves toughness and edge stability. Together, these elements make CPM T15 a formidable choice in the realm of high-speed tool steels.

How does the microstructure of CPM T15 affect its performance?

The microstructure of CPM T15, which is a result of the powder metallurgy process, plays a crucial role in its performance. A fine and uniform grain structure allows for increased toughness and edge retention, making it ideal for demanding cutting tasks. This refined microstructure also enables the achievement of the desired hardness levels without compromising the steel’s overall durability.