Get in touch with us

Leave a message

For pricing information on Hastelloy C2000 Plate, please contact our team to obtain a customized quote. Pricing terms depend on order specifications, quantity, and shipping preferences.

Hastelloy C2000 Plate is widely used in industries such as:

| Element | Percentage(% |

|---|---|

| Nickel (Ni) | 1. 0 min |

| Chromium (Cr) | 1 |

| Molybdenum(Mo) | 1 |

| lron (Fe) | 1.0 max |

| Copper (Cu) | 1.6 max |

| Others | Balanced |

| Properties | Value |

|---|---|

| Tensile Strength | 690 MPa (minimum) |

| Yield Strength | 310 MPa (minimum) |

| Elongation | 40%(minimum) |

| Density | 1. 69 g/cm³ |

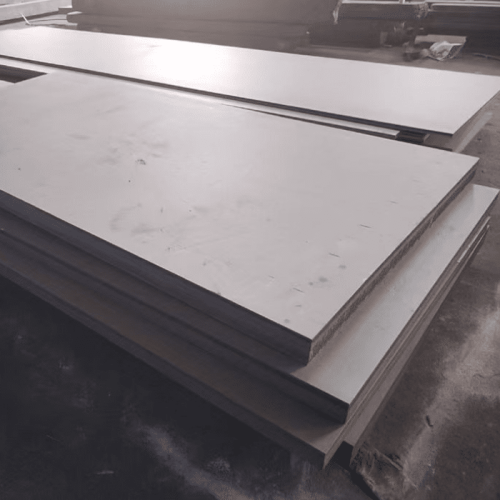

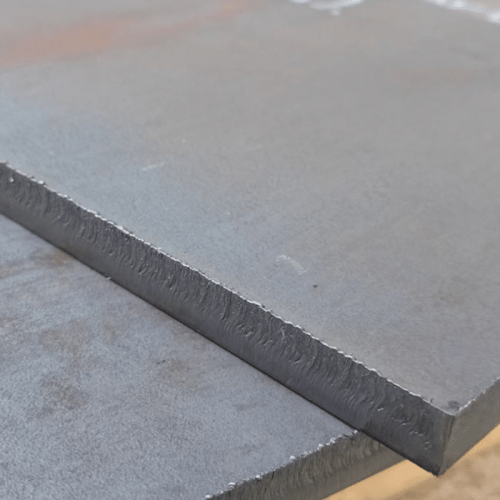

Hastelloy C2000 Plate demonstrates unparalleled resistance to corrosive chemicals, particularly sulfuric acid, hydrochloric acid, and nitric acid. It maintains stability even under fluctuating oxidizing and reducing conditions, ensuring long-term reliability in aggressive environments.

While Hastelloy C2000 is remarkably versatile, it has some limitations, including its performance in environments where extremely high temperatures exceed recommended thresholds. The material should also be handled with caution during welding, as improper techniques can result in a loss of corrosion resistance.

Hastelloy C2000 Plate offers resistance to atmospheric corrosion and mild chemical exposure. It can withstand high concentrations of acids, ensuring structural integrity in demanding settings.

The alloy supports a variety of welding methods, including TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas). Pre-heating is not required, but post-weld heat treatment is recommended for optimal performance. The material’s malleability makes it ideal for forming, but care should be taken to avoid contamination during processing.

This China manufacturer provides high-quality Hastelloy C2000 Plate, ideal for our chemical plant operations.

Johnson W.

Operations Manager

The hastelloy metal’s corrosion resistance is exceptional for high-temperature alloy applications.

Anthony B.

Technical Lead

Reliable hastelloy grades from trusted hastelloy plate suppliers. Great service!

Jenny F.

Procurement Officer

A: Hastelloy C2000 Plate has better resistance to reducing acids due to copper, while C276 excels in oxidizing conditions.

A: Chemical processing, pharmaceuticals, pulp and paper, and oil and gas sectors.

A: Yes, up to 1900°F, but avoid prolonged exposure beyond this limit.

A: Yes, our China factory is a premier distributor of Hastelloy C2000 Plate.

A: Industries such as chemical processing, marine, power generation, and pharmaceuticals benefit greatly from its versatile properties.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.