Get in touch with us

Leave a message

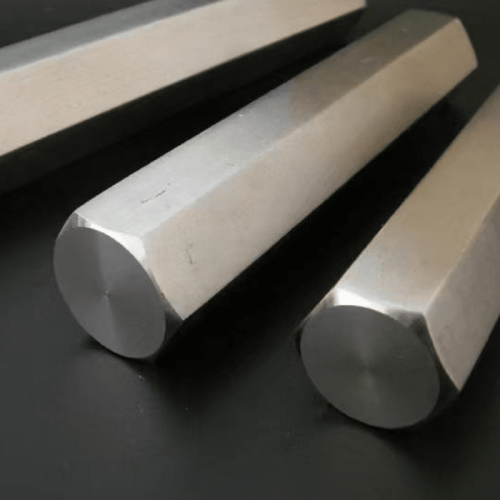

Hastelloy B3 Bar, a nickel-molybdenum superalloy, excels in extreme corrosive environments. Known for its outstanding resistance to hydrochloric acid and other aggressive chemicals, this hastelloy material is ideal for demanding industrial applications.

Contact our sales team for a quote on Hastelloy B3 Bar pricing and terms.

Hastelloy B3 Bar is widely used in industries requiring corrosion resistant alloys, including:

| Element | Percentage (%) |

|---|---|

| Nickel | 65.0 min |

| Molybdenum | 28.5 |

| Iron | 1.5 max |

| Chromium | 1.5 max |

| Others | Co, Mn, Si, C (trace amounts) |

| Property | Value |

|---|---|

| Tensile Strength | 760 MPa (min) |

| Yield Strength | 350 MPa (min) |

| Elongation | 40% (min) |

| Hardness | HB 210 (max) |

Hastelloy B3 Bar offers exceptional resistance to acids like hydrochloric, sulfuric, and phosphoric. It performs well in reducing environments but is not suitable for oxidizing conditions.

The Hastelloy G30 Bar has constraints:

Our China distributor can recommend alternatives if needed.

Use TIG or MIG welding for Hastelloy B3 Bar. It supports forming and machining, but low cutting speeds are advised due to its strength. Anneal after fabrication for optimal results.

Hastelloy B3 Bar excels in our acidic reactors. Excellent durability!

Alan R.

Chemical Engineer

Perfect for high-stress components. Great corrosion resistance.

Clara M.

Aerospace Supplier

Reliable in harsh conditions. Top China manufacturer.

Tom L.

Oil & Gas Distributor

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.