Get in touch with us

Leave a message

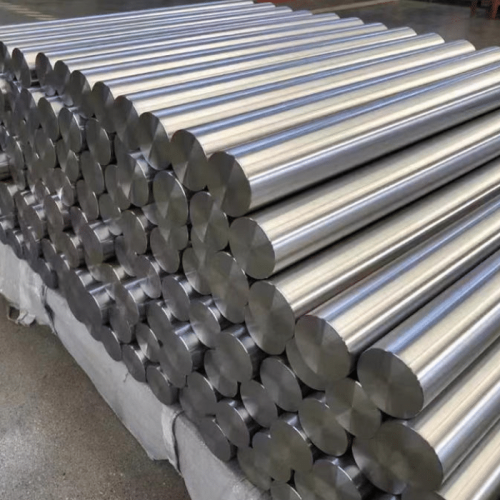

Hastelloy C2000 Bar, a premier corrosion-resistant alloy, offers unmatched resistance to aggressive chemicals and high temperatures. This superalloy excels in industries requiring durability, such as chemical processing and power generation. Its unique hastelloy composition ensures reliability in extreme environments.

Contact our sales team for competitive pricing on Hastelloy C2000 Bar. Flexible terms tailored to your needs.

Hastelloy C2000 Bar is widely used in:

| Element | Percentage (%) |

|---|---|

| Nickel | 59 (Balance) |

| Chromium | 23 |

| Molybdenum | 16 |

| Copper | 1.6 |

| Iron | 3 max |

| Carbon | 0.01 max proposal |

| Property | Value |

|---|---|

| Tensile Strength | 760 MPa (min) |

| Yield Strength (0.2% offset) | 360 MPa (min) |

| Elongation | 40% (min) |

| Hardness (Brinell) | 210 (max) |

Hastelloy C2000 Bar resists:

Environmental Restrictions: Avoid prolonged exposure above 1900°F to prevent embrittlement.

While Hastelloy C2000 Bar offers outstanding performance, certain limitations include:

Hastelloy C2000 Bar offers industry-leading resistance to various corrosive environments, including:

Hastelloy C2000 Bar can be welded using conventional methods, including GTAW and SMAW. It demonstrates excellent workability and can be fabricated into complex shapes without compromising its corrosion resistance.

The quality of Hastelloy C2000 Bar exceeded our expectations. It performs incredibly well in aggressive environments.

John D.

Procurement Manager

We appreciate the exceptional durability and corrosion resistance of this product in our chemical processing plant.

Jane R.

Technician

Highly recommend this bar for applications requiring both strength and reliability.

Ahmed K.

Operations Lead

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.