Get in touch with us

Leave a message

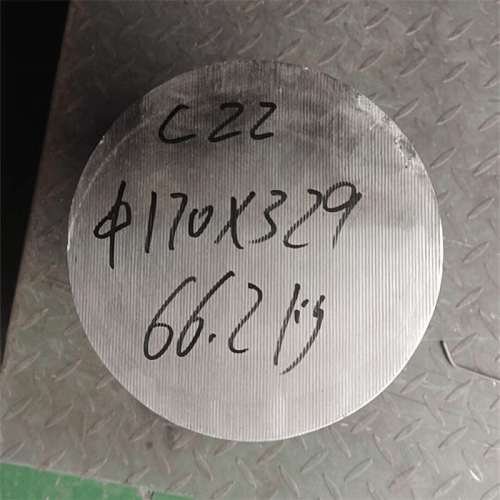

The Hastelloy C22 Round Rod serves critical industries:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | Balance |

| Chromium (Cr) | 20.0–22.5 |

| Molybdenum (Mo) | 12.5–14.5 |

| Iron (Fe) | 2.0–6.0 |

| Tungsten (W) | 2.5–3.5 |

| Cobalt (Co) | ≤ 2.5 |

| Manganese (Mn) | ≤ 0.5 |

| Silicon (Si) | ≤ 0.08 |

| Carbon (C) | ≤ 0.015 |

| Phosphorus (P) | ≤ 0.02 |

| Sulfur (S) | ≤ 0.02 |

| Property | Value |

|---|---|

| Tensile Strength | 690–950 MPa |

| Yield Strength (0.2%) | ≥ 310 MPa |

| Elongation | ≥ 45% |

| Hardness (Brinell) | ≤ 240 HB |

| Density | 8.69 g/cm³ |

The Hastelloy C22 Round Rod resists:

The Hastelloy C22 Round Rod has minimal constraints:

Our China distributor can advise on alternatives if needed.

| Environment | Corrosion Resistance | Notes |

|---|---|---|

| Atmospheric (All Conditions) | Excellent | Resists rust in humid, salty, or polluted air. |

| Saltwater (Marine) | Excellent | Outstanding resistance to pitting and crevice corrosion. |

| Strong Acids (e.g., Nitric) | Excellent | Superior in oxidizing acids; also handles reducing acids. |

| Alkaline Solutions | Excellent | Strong resistance to bases like sodium hydroxide. |

| Chloride Solutions | Excellent | Highly resistant to chloride-induced stress corrosion. |

Contact us for detailed corrosion resistance data specific to your application.

Welding Hastelloy C22 Round Rod is straightforward:

Tips:

Our China factory offers pre-machined options for ease.

Laura K.

Chemical Engineer

Tom S.

Plant Manager

Mike R.

Technician

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.