High strength steel bars, often referred to as Fe-tensile marvels, are transforming industries with their unparalleled durability and versatility. These advanced materials have become a critical component in sectors such as construction, infrastructure, and manufacturing, offering solutions to meet the growing demand for stronger, lighter, and more sustainable structures. This guide dives deep into the fascinating world of high strength steel bars, exploring their unique properties, manufacturing processes, and the innovative ways they are being utilized today.

The article begins by breaking down the science behind these steel bars, highlighting the key metallurgical principles and fabrication techniques that give them their extraordinary strength. From there, we examine real-world applications across various industries, showcasing how they are revolutionizing engineering and design. Additionally, we address the environmental impact of these materials, focusing on their role in creating eco-friendly solutions without compromising performance.

Whether you’re new to the topic or a seasoned professional looking to expand your knowledge, this guide is designed to provide a comprehensive understanding of high strength steel bars and their growing significance. Join us as we unveil the true potential of these remarkable materials and their role in shaping a resilient and sustainable future.

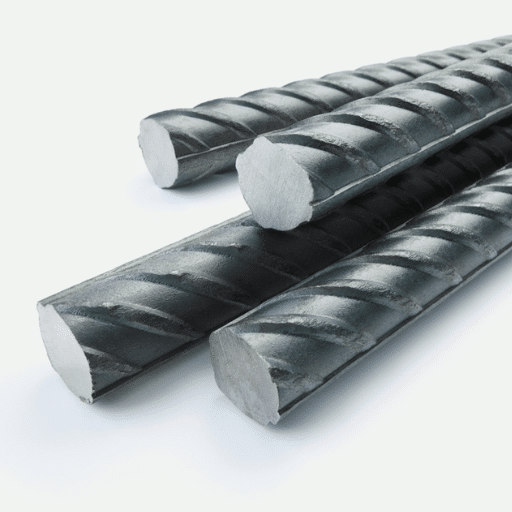

What are high strength steel bars and how are they different from regular steel bars?

High strength steel bars are specialized construction materials designed to provide superior mechanical properties, such as higher tensile strength and durability, compared to regular steel bars. These bars are engineered through advanced alloying techniques and heat treatment processes to enhance their structural performance under extreme loads and challenging conditions. Unlike regular steel bars, which are primarily used for basic support, high strength steel bars offer increased resistance to stress, corrosion, and fatigue, making them ideal for applications in high-rise buildings, bridges, and other demanding infrastructure projects. Their enhanced performance also allows for reduced material use, promoting cost efficiency and sustainability.

Understanding the composition of high strength steel

High strength steel derives its superior properties from carefully combining elements and advanced production techniques. Its composition typically includes a mix of carbon, manganese, and silicon, with additional alloying elements like chromium, nickel, or molybdenum to enhance specific characteristics such as tensile strength, corrosion resistance, and durability. The steel undergoes precise heat treatment processes, such as quenching and tempering, to refine its microstructure and achieve the desired mechanical properties. Micro-alloying with small amounts of vanadium, niobium, or titanium further boosts strength and toughness while maintaining weldability and formability. These features enable high-strength steel to meet the rigorous demands of modern construction and engineering projects.

Comparing mechanical properties: High strength vs. regular steel bars

High-strength steel bars significantly outperform regular steel bars in critical mechanical properties like tensile strength, yield strength, and ductility. High-strength steel typically offers tensile strengths ranging from 400 MPa to over 1,200 MPa, compared to regular steel, which generally does not exceed 300 MPa. This increased strength allows for lighter designs and reduced material usage without compromising structural integrity.

Another crucial factor is yield strength, which is also markedly improved in high-strength steel bars. Their ability to sustain higher loads before deforming permanently makes them ideal for applications in high-stress environments like bridges, skyscrapers, and industrial machinery. Conversely, regular steel bars may be adequate for less demanding projects but lack the advanced load-bearing capabilities required for modern engineering standards.

Additionally, high-strength steel maintains good ductility, enabling it to withstand significant stress without fracturing, making it safer under extreme conditions such as seismic activity. Regular steel, while more malleable, tends to deform more easily under similar stresses. This comparison highlights why high-strength steel bars are integral to the advancement of construction and engineering projects demanding peak performance.

Key advantages of using high-strength steel bars in construction

- Enhanced Durability and Longevity: High-strength steel bars are specifically designed to withstand high-stress levels without deformation, ensuring the structural integrity of buildings over time. Their corrosion resistance further increases their lifespan, reducing maintenance costs.

- Improved Safety Standards: These bars demonstrate excellent ductility, meaning they can absorb significant energy during events such as earthquakes or heavy loads, minimizing the risk of sudden structural failure and enhancing overall safety.

- Cost-Efficiency: Despite their higher initial cost, the improved performance and longevity of high-strength steel bars reduce the need for frequent repairs, leading to lower long-term expenses for construction projects.

- Sustainability: High strength steel bars are often recyclable, aligning with modern sustainable construction practices. The reduced material quantity required for similar performance also minimizes environmental impact.

- Versatility: Their high tensile strength and adaptability make them suitable for a variety of construction projects, including skyscrapers, bridges, and industrial facilities, ensuring reliable performance across demanding applications.

This combination of benefits positions high strength steel bars as a critical material in shaping the future of resilient and efficient infrastructure.

What are the most common applications for high strength steel bars?

High-strength steel bars are commonly used in a wide range of construction and engineering applications. They are vital in reinforcing concrete structures such as bridges, highways, and buildings, providing enhanced durability and load-bearing capacity. Additionally, due to their strength and flexibility, they are integral to the construction of skyscrapers and industrial facilities. Other applications include heavy machinery, infrastructure development, and specialized projects requiring reliable structural support. Their versatility makes them indispensable in both traditional and modern construction scenarios.

High strength steel bars in building structures and skyscrapers

High strength steel bars are pivotal in modern construction due to their superior mechanical properties and versatility. They provide exceptional tension and compression resistance, making them ideal for withstanding heavy loads and dynamic forces in skyscrapers and large-scale building projects. Their high yield strength allows engineers to use less material while maintaining structural integrity, which is cost-effective and environmentally sustainable by reducing resource consumption. Furthermore, their durability under extreme conditions, such as seismic activity or high winds, ensures the longevity and safety of structures. These features contribute significantly to the advancement of innovative architectural designs and the growth of urban infrastructure.

Use of high-strength steel bars in bridges and infrastructure

High-strength steel bars are vital in modern bridges and infrastructure, offering exceptional load-bearing capacity and resilience. These steel bars are crucial for reinforcing concrete structures, providing enhanced tensile strength that helps withstand heavy traffic loads, seismic forces, and environmental stressors. Their use reduces the overall volume of material required while maintaining structural integrity, making them cost-effective and sustainable. Additionally, the ductility of high strength steel bars ensures flexibility in design, enabling the construction of complex, innovative architectural structures. By improving the safety and longevity of bridges and other infrastructure, these bars create durable and reliable transportation networks essential for growing urban environments.

Industrial applications: machinery and heavy equipment

High-strength steel bars play a vital role in machinery and heavy equipment due to their exceptional durability and resistance to wear. These bars are commonly used to manufacture components such as gears, shafts, and axles, where strength and precision are crucial. Their ability to withstand high-stress environments ensures the reliable performance of equipment used in mining, construction, and transportation industries. Additionally, the high load-bearing capacity of these steel bars enhances operational efficiency, making them an ideal choice for heavy-duty applications. Their corrosion resistance further extends the lifespan of machinery, reducing maintenance costs and downtime in demanding industrial settings.

How do manufacturers ensure the quality and strength of high strength steel bars?

Manufacturers ensure the quality and strength of high-strength steel bars through rigorous processes such as material selection, advanced heat treatments, and precise alloy composition. Thorough quality control measures, including tensile strength tests, hardness assessments, and microstructural analysis, confirm that the bars meet industry standards. Additionally, continuous monitoring during production ensures uniformity and adherence to specifications, guaranteeing performance in demanding applications.

Understanding steel grades and specifications for high-strength bars

Steel grades and specifications for high-strength bars are defined by a combination of chemical composition, mechanical properties, and manufacturing standards, ensuring optimal performance for specific applications. The most common classification systems include the American Society for Testing and Materials (ASTM), European Standards (EN), and Japanese Industrial Standards (JIS). For example, grades such as ASTM A615 focus on high tensile strength and ductility for construction reinforcement, while ASTM A706 emphasizes weldability and resistance to stress-related cracking.

High-strength bars often incorporate alloying elements like chromium, molybdenum, and vanadium to enhance hardness, tensile strength, and corrosion resistance. Heat treatment processes, including quenching and tempering, further refine the microstructure to achieve desired performance characteristics. Specifications typically outline yield strength, minimum elongation, and impact resistance requirements, ensuring the material can endure extreme loads and harsh conditions.

By adhering to these stringent standards, manufacturers ensure that high-strength steel bars meet the demands of industries such as construction, automotive, and energy infrastructure, where safety and reliability are paramount. Understanding these grades and specifications enables engineers and designers to select the most appropriate materials for their innovative and demanding projects.

The role of heat treatment in enhancing steel bar strength

Heat treatment plays a critical role in enhancing the strength and performance of steel bars by altering their internal structure through controlled heating and cooling processes. Standard methods include annealing, quenching, and tempering, each designed to achieve specific mechanical properties. Quenching, for example, involves rapidly cooling heated steel to increase hardness, while tempering reduces brittleness by reheating and cooling at a slower rate. These processes refine the microstructure, enhance ductility, and optimize the balance between strength and toughness. By tailoring heat treatment techniques to the desired application, manufacturers can produce steel bars that meet the stringent requirements of industries such as construction, automotive, and heavy machinery, ensuring durability and reliability under demanding conditions.

Testing methods for tensile strength and yield strength

Two primary methods are commonly employed to evaluate tensile strength and yield strength: tensile testing and hardness testing. Tensile testing involves using a universal testing machine (UTM) to pull a material sample until it fractures, recording data such as the maximum stress it can withstand (tensile strength) and the point at which it begins to deform permanently (yield strength). The stress-strain curve generated during this test provides critical information about the material’s mechanical properties.

While not a direct measurement, hardness testing can be used as an alternative to estimate tensile and yield strength based on established conversion charts. Methods like the Brinell, Rockwell, or Vickers hardness tests are widely used, especially for quality control purposes in industrial settings. Both methods ensure that the material meets the standards required for specific applications, enabling manufacturers to guarantee performance and safety in critical environments.

How do high-strength steel bars contribute to sustainable construction practices?

High strength steel bars contribute to sustainable construction practices by reducing the raw materials required due to their superior strength-to-weight ratio. This leads to lighter structures and lower material usage, which minimizes resource extraction and waste. Additionally, they enhance the durability and lifespan of buildings, reducing the need for frequent repairs or replacements. Many high-strength steel bars are also recyclable, supporting a circular economy and reducing environmental impact. These characteristics align with the principles of sustainable development by promoting efficiency and eco-friendly practices in construction.

Reducing material usage through higher strength-to-weight ratios

High-strength steel bars with superior strength-to-weight ratios allow for significant reductions in material usage without compromising structural integrity. By requiring less material to achieve the same load-bearing capacity, these bars contribute to lighter construction designs, reducing overall resource consumption. This innovation lowers production costs and decreases transportation and installation efforts due to the reduced weight. Furthermore, the enhanced efficiency aligns with modern engineering practices that minimize environmental footprints while maintaining safety and durability in construction projects.

Longevity and durability of high-strength steel structures

High strength steel structures are renowned for their resilience and long lifespan, even under demanding conditions. These materials resist deformation, corrosion, and fatigue better than conventional steel, thanks to their advanced manufacturing processes and protective coatings. Their ability to withstand extreme weather, seismic activity, and heavy loads makes them an ideal solution for durable infrastructure. Additionally, proper maintenance, such as regular inspections and timely repairs, further enhances their longevity. With advancements in engineering and material sciences, high-strength steel contributes to sustainable and cost-efficient construction projects by reducing the need for frequent replacements or extensive repairs over time.

Recyclability and environmental impact of high-strength steel

High strength steel is one of the most environmentally friendly construction materials due to its exceptional recyclability. It can be recycled countless times without losing quality or strength, significantly reducing the demand for raw materials and energy-intensive production processes. On average, steel recycling rates exceed 85%, with some applications achieving nearly 100%, making it a vital component in a circular economy.

The production of high-strength steel also supports sustainability by reducing the quantity of material needed for projects without compromising safety or performance. This leads to lighter structures, which require less transportation energy and resources. Additionally, advancements in steel manufacturing have led to decreased carbon emissions and improved energy efficiency, minimizing its environmental footprint. By prioritizing recyclability and sustainable production, high-strength steel plays a key role in reducing waste and supporting global efforts to mitigate environmental impact.

What are the latest innovations in high-strength steel bar technology?

Recent advancements in high-strength steel bar technology have focused on improving performance and sustainability. Key innovations include the development of microalloyed steels, which use small amounts of alloying elements to enhance strength, durability, and weldability. Thermomechanical processing techniques have also progressed, allowing for precise control over the steel’s grain structure to optimize its mechanical properties. Additionally, surface engineering technologies, such as advanced coatings, now provide enhanced corrosion resistance, extending the lifespan of steel bars. These innovations improve the efficiency and safety of construction projects and align with global sustainability goals by reducing material wastage and energy consumption.

Advancements in alloy compositions for enhanced properties

Recent developments in alloy compositions have significantly improved the properties of high-strength steel bars. Manufacturers can achieve superior strength and toughness without compromising on ductility by incorporating elements such as vanadium, niobium, and titanium in precise proportions. These microalloying techniques refine the grain structure of the steel, enhancing its resistance to fatigue and deformation under stress. Furthermore, including chromium and molybdenum in innovative alloy designs has boosted corrosion resistance, making these steels highly suitable for demanding environments like marine and industrial applications. Such advancements not only enhance the performance of steel bars but also contribute to longer structural lifespans, aligning with sustainability and cost-efficiency goals in the construction industry.

Smart steel bars: integrating sensors for structural health monitoring

Bright steel bars represent a groundbreaking development in modern construction. They incorporate embedded sensors to monitor the structural health of buildings and infrastructure in real time. These sensors, often based on technologies such as fiber optics, piezoelectric materials, or wireless transmitters, can detect strain, temperature changes, and even early signs of structural damage. Providing continuous data enables predictive maintenance, enhancing both safety and longevity.

Integrating sensors within steel bars eliminates invasive inspections, offering a streamlined solution for large-scale projects like bridges, skyscrapers, and tunnels. This technology supports proactive decision-making, reducing repair costs and mitigating risks associated with structural failures. Additionally, smart steel bars contribute to sustainability by optimizing materials usage and extending the service life of structures through precise monitoring. Combining innovation with practicality, these intelligent systems highlight a new era in construction that prioritizes safety, efficiency, and environmental responsibility.

Nano-enhanced high strength steel bars

Nano-enhanced high-strength steel bars integrate advanced nanotechnology to improve the performance of traditional steel. By incorporating nanoparticles into the steel matrix, these bars achieve superior strength, enhanced ductility, and improved resistance to corrosion and fatigue. This makes them ideal for critical infrastructure projects, including bridges, highways, and high-rise buildings, where durability and resilience are paramount.

The primary benefits include increased load-bearing capacity, reduced material usage due to their high strength-to-weight ratio, and extended service life even in harsh environments. Furthermore, their nano-enhanced structure offers better energy absorption, making them highly effective in regions prone to seismic activity. The cost-effectiveness of these bars is another key advantage, as their enhanced durability minimizes long-term repair and maintenance expenses.

Nano-enhanced high strength steel bars also play a crucial role in advancing sustainable construction. By reducing the overall material demand and increasing the lifespan of structures, they contribute to lower environmental impact. This innovative approach merges cutting-edge technology with practical construction needs, setting a new benchmark for efficiency and reliability in the construction industry.

How to choose the right high strength steel bar for your project?

When selecting the right high-strength steel bar for your project, consider the specific requirements of your structure and environment. Start by evaluating the load-bearing capacity needed and the external conditions the bars will face, such as seismic activity, temperature extremes, or corrosion risks. Check the material’s certification and standards compliance to meet quality assurance criteria. Additionally, factor in the cost-effectiveness by comparing the initial investment with potential long-term savings from durability and reduced maintenance. Lastly, consult with professionals or suppliers to match the appropriate nano-enhanced or traditional steel bar to your project’s unique demands.

Assessing project requirements: strength, durability, and cost considerations

Strength Requirements

When determining the strength requirements for your project, consider the maximum loads the structure will bear and any potential stress factors, such as wind, seismic activity, or vibration. High strength steel bars, like those made from advanced alloys or reinforced with nano-enhanced technology, offer superior tensile strength to withstand these demands effectively. Compare various options’ yield strength (psi or MPa) to ensure compliance with your structural needs.

Durability Considerations

Durability is crucial for long-term functionality and safety. Assess environmental factors such as exposure to moisture, chemicals, or temperature fluctuations. For projects in high-corrosion zones, opt for steel bars coated with zinc or epoxy to improve resistance. Nano-enhanced steel or options with superior fatigue resistance are ideal for areas prone to seismic events or heavy use. Ensure the material complies with industry standards like ASTM International certifications to meet quality benchmarks.

Cost-Benefit Analysis

Balancing upfront costs with long-term value is key. While high-performance steel bars may have a higher initial cost, their extended lifespan and reduced maintenance expenses often justify the investment. Compare suppliers to ensure competitive pricing and factor in warranties or after-sales support. Prioritize solutions tailored to your project’s specific needs to achieve the most cost-effective outcome without compromising quality or safety.

Comparing different types of high-strength steel bars: round, flat, and hex

When selecting high-strength steel bars, understanding the specific attributes of each type is essential.

Round Bars are highly versatile and commonly used in construction, automotive, and machinery applications. Their circular cross-section ensures uniform strength distribution, making them ideal for rotational components like gears, shafts, and bolts. They are easy to machine and widely available in various diameters.

Flat Bars: Designed for their broad, rectangular cross-section, flat bars are perfect for structural and architectural applications where flat surfaces are required. Their shape gives construction beams and frames and supports superior load-bearing capacity. Flat bars are often preferred for fabrication due to their consistent thickness and ease of cutting or welding.

Hex Bars: Hexagonal bars offer excellent strength and are commonly used to manufacture fasteners, nuts, and specialty components. Their unique geometry enhances grip and torque capabilities, making them a favorite in the mechanical and automotive industries. They also provide precision and stability in applications requiring intricate machining.

Each steel bar type serves specific purposes, and the choice depends on factors such as structural demands, machining requirements, and end-use applications. You can ensure optimal performance and cost-effectiveness by evaluating their characteristics and matching them with project needs.

References

Frequently Asked Questions (FAQ)

Q: What are the main advantages of using high-tensile steel bars in construction?

A: High tensile steel bars offer superior strength and durability, making them ideal for heavy construction projects. They are favored for their high yield strength and the ability to be used in a wide range of applications, including structural steel components.

Q: How do high-strength steel bars’ chemical composition and wear resistance impact their performance?

A: The chemical composition of high-strength steel bars, often enriched with elements like chromium, enhances their wear resistance and toughness. This combination makes them suitable for demanding environments where durability is crucial.

Q: Are high-strength steel bars easy to weld, and what should be considered during fabrication?

A: High-strength steel bars can be readily welded with proper equipment and knowledge. However, to ensure strong and reliable joints, it’s important to consider their weldability and the need for specific welding techniques.

Q: What differentiates a bright bar from a standard steel round bar?

A: A bright bar is a type of steel bar that has been cold-finished to achieve a smooth surface finish and tighter tolerances. This makes it ideal for applications requiring precise dimensions and aesthetic appeal, such as in producing machinery components.

Q: Can carbon steel bars be used in applications requiring high toughness?

A: Yes, carbon steel bars are widely used in applications requiring high toughness. They offer a balance of strength and toughness, making them suitable for various industrial uses, including heavy construction and machinery manufacturing.

Q: What are the typical uses of a steel round bar in industrial settings?

A: Steel round bars are used in industrial settings for a variety of purposes, including the manufacture of machinery and equipment, construction of structural components, and as raw material for further processing into other steel products.

Q: How does the hardness of a high-strength steel bar affect its use in manufacturing?

A: The hardness of a high-strength steel bar determines its ability to resist deformation and wear. This property is crucial in manufacturing applications where the steel bar must maintain its shape and functionality under stress.

Q: What role does heat treatment play in enhancing the properties of high-tensile steel bars?

A: Heat treatment processes, such as quenching and tempering, enhance the properties of high-tensile steel bars by improving their strength, hardness, and wear resistance, making them suitable for demanding industrial applications.

Q: Why is it important to consider the variety of grades available in steel round bars?

A: Different grades of steel round bars offer varied mechanical properties and chemical compositions, making it easy to select the appropriate grade for specific applications. This ensures optimal performance and longevity in their intended use.

Q: How can customers get more information or assistance regarding steel bars?

A: Customers can contact us for further information or assistance regarding steel bars. Our team can provide expert advice on selecting, using, and maintaining steel products tailored to specific requirements.