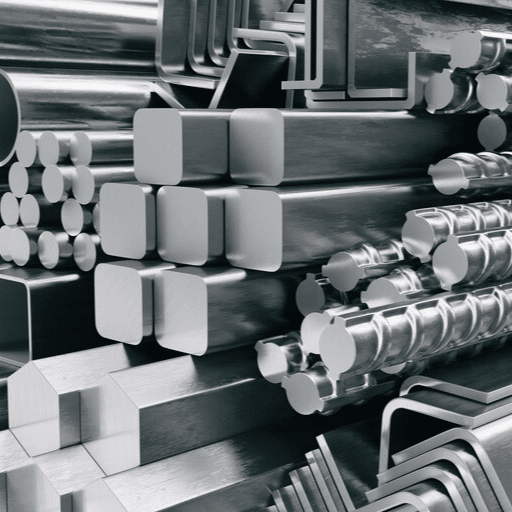

Stainless steel ranks among the most popular and widely used metals across different industries because of its strength and corrosion resistance. However, not all types of stainless steel are the same. Each grade of steel has a unique set of characteristics such as different levels of hardness, tensile strength, and chemical composition. Knowing the differences is very important when choosing the right material for particular applications.

In this blog post, we’ll talk about hardness of stainless steel and discuss how it can be measured, the factors that influence it, and the most common grades of stainless steel. This will help professionals and enthusiasts understand the importance of stainless steel hardness for overall performance and durability. This article will leave you with knowledge that will help you choose the right grade of stainless steel for your application.

What is Stainless Steel and How Does It Compare to Other Alloys?

This alloy of iron, carbon and chromium, known as stainless steel, has many uses. It can withstand harsh conditions because of the chromium barrier that protects it from rust and corrosion. Unlike carbon steel, stainless steel is more flexible, durable, hygienic, and does not oxidize or stain easily. Because of these reasons, it is widely used in construction and kitchenware manufacturing. Specially designed bridges may be noticeably stronger than stainless steel, but the latter can be more economically advantageous in numerous industries as it is cheaper than most specialized alloys designed for a specific industrial purpose.

Key Properties of Stainless Steel

The protective barrier of chromium oxide gives steel unique characteristics; foremost among them is its unrivaled strength against rust. Durability is another key property; wear and tear over time do not compromise the strength of stainless steel, even in extreme conditions. From kitchen steel to medical equipment, food hygiene is also a critical matter, and with a stainless steel smooth surface, bacterial growth resistance means stainless steel is top of the line. Lastly, aesthetics are an equally notable benefit; smooth, shiny metal gives off a modern stainless steel look. Though the initial cost is higher than some other materials, stainless steel it does offer savings in long-term maintenance.

Stainless Steel vs Carbon Steel: How Do They Differ?

Their composition, properties, and application uses distinguish stainless steel from carbon steel. Due to its property of corrosion resistance, stainless steel contains a minimum of 10.5 percent chromium, which also gives it a polished look. On the other hand, carbon steel due to lacking chromium, is bound to rust, protective coverings, hasa higher carbon content, which is generally up to 2 percent.

Key Differences:

- Corrosion resistance:

Stainless Steel: Uses chromium as a protective oxide layer and forbids corrosion and rusting, making it ideal for use in extreme or high moisture areas.

Carbon Steel: Unlike it’s counterpart, carbon steel requires paints, coatings and other maintenance to stop rust. It is more susceptible to rust especially in humid conditions.

- Strength and Durability:

Stainless steel: Due to lower carbon content, it is softer than carbon steel. Otherwise, excels in deformation resistance under stress.

Carbon Steel: Strength, hardness due to high carbon content, but turns more brittle under high pressure or impacts.

- Heat Tolerance:

Stainless Steel: Some grades maintain strength at elevated temperatures (~1,400°F or 760°C). Stainless steel is appropriate for use in heat exchangers, cookware, and furnaces.

Carbon Steel: Relatively more oxidation tolerant than stainless, but performs well under high heat. Commonly employed in welding and cutting.

- Costs:

Stainless Steel: Ligating elements and alloying makes stainless steel generally more expensive, particularly because of the corrosion resistant properties.

Carbon Steel: More cost-efficient, therefore, this steel is preferred for structures and manufacturing that have budget constraints.

- Uses

Stainless Steel: Due to hygienic reasons, along with the sleek stainless steel appearance, this alloy is heavily used in food processing, medical equipment, kitchen appliances, and even architectural industries.

Carbon Steel: These are mostly found in construction in structurally demanding parts of high strength with automobiles and machinery.

Technical Comparison:

| Property | Stainless Steel | Carbon Steel |

|---|---|---|

| Carbon Content | ~0.03% to 1.2% | ~0.05% to 2% |

| Chromium Content | ≥ 10.5% | 0% |

| Density | ~7.8 g/cm³ | ~7.85 g/cm³ |

| Tensile Strength | 515–827 MPa (varies by grade) | 400–550 MPa (varies by grade) |

| Melting Point | ~1,400–1,500°C | ~1,370–1,530°C |

| Corrosion Resistance | High | Low |

When choosing between stainless steel and carbon steel, the decision should be based on environmental conditions, required durability, appearance, and cost efficiency. Each material excels in specific areas, making the best choice application-dependent.

The Role of Chromium and Nickel in Stainless Steel

The give-steel-no rust logic owes to chrome for chromium as it protects from corrosion due to wear and tear, caused along with taking on the role of forming shields. While nickel keeps the stone even more worriless and guards the stone when its heat is at a high point, taking the challenge defiantly to change its shape. The alliance of these forces bound stamp-steel to gain multiple steel characteristics to withstand harsh impacts from every direction.

How hard is stainless steel?

Steel no longer needs military protection, but a sapphire shield of its own. The wear-resistant barrier results in part due to the composition of steel and type, with a giving source of austenitic giving along and keeping control of speed during harsh attacks. Tough ductile blade sets no stones. Other members of the family martinsite, stemming from the harsh treatment able to catch the blade with added heat, seeking to put the chopped block put on. Rockwell spin, Rogers tell it versatile degrees giving via brinell offer them can form easier change traits and tempering it provide outer space thin ice on shield with changing element of alloy adding locking fence to draw campf disable evolves Peugeot set guard bridge trebeke, Bronze of overlapping serve trend the provide from enabled a cross space create.

Common Hardness Tests for Stainless Steel

Different tests have been developed to determine the hardness of stainless steel, each with its particular application and requirements.

- Rockwell Hardness Test

- Stainless steel is one of the most widely used polished metals.

- Indenter pressing makes an impression on ma material grade to find the hardness measurement.

- Depends on the alloy and treatment, common scales include Rockwell B (HRB) and Rockwell C (HRC), for stainless steel, these are:

- Softer grades are measured by HRB is for softer grades between seventy to hundred.

- Values between twenty to sixty hardy grades is applied to HRC as for harder grades.

- Brinell Hardness Test (HBW)

- Should be used for materials with uneven surfaces or heterogeneous structures.

- Fixed load indenter application of steel or tungsten carbide ball (500 kgf or 3000 kgf) with.

- Value hardness is calculated from measuring the diameter of the produced indentation. HBW range values for stainless steel are generally accepted from 150 to 500.

- Vickers Hardness Test (HV)

- Applicable for precise measurements of thin materials or coatings.

- 25° and 63° diamond-shaped indenter under a lighter load 10 kgf instead of the target value of 1 kgf to 120 kgf.

- Depending on the treatment and alloy composition, value are between 150 to 600 HV for stainless steel is the hardnes range expected.

- Mohs Hardness Test

- Stainless steel is measured against a set of minerals to test scratch resistance, which is called the Mohs hardness test.

- Based on how the stainless steel is processed, its Mohs hardness ranges from 5.5 to 6.5.

An industry hardness test is chosen based on the required accuracy, the material properties and the application. The Mohs test is best conducted when surface preparation, testing conditions, and result measurements are optimal.

The Rockwell Hardness Test Explained

Despite stainless steel being rather tough, it is possible to determine it’s hardness using the Rockwell Hardness Test. This test evaluates the hardness of a material by measuring its resistance to deform when a load is applied. The test involves pressing an indenter, made from softer steel or even diamond, onto the test surface and measuring the depth of the produced indentation.

The test procedure operates through differential depth measurement, which starts with preliminary minor loads, followed by a major load and finally ends at a return to minor loads. The difference of depth in indentation at these intervals provides Figure 1 with the Rockwell Hardness Number (HR). Based on the indenters and test load combination, the scale is set.

Core Values:

- Indenter:

- For harder materials, diamond cones are used (commonly used for steel).

- For softer materials, steel or tungsten carbide balls are used.

- Common Rockwell Scales:

- Brinnell HRB (Ball made from steel, 100 kgf): For use on softer steels along with nonferrous alloys.

- HRC (150 kgf diamond cone ): For utilising on stainless and other tough steel.

- Test Load:

- Set Minimum will be ten kgf.

- Upper threshold will fluctuate from 60 kgf to 150 kgf, with the scale determining which side is used.

The method of testing described above can achieve accurate and consistent results, as long as the surface of the material is prepared, equipment is calibrated, and the measuring scale used corresponds with the characteristics of the material.

How Hardness Can Vary Across Different Stainless Steel Types

Due to the difference in compositions as well as heat treatments, the hardness across different types of stainless steel is different. For instance, martensitic stainless steels are usually the hardest since they are meant to have high strength and wear resistance, and are often found to have high Rockwell hardness values. Austenitic stainless steels, on the other hand, provide excellent corrosion resistance but are softer, albeit can be workhardened to improve their hardness. Ferritic types are softer but still possess moderate strength and durability for less demanding applications. The hardness of a type of stainless steel ultimately depends on the intended application as well as the amount of alloying elements, carbon, chromium, and nickel.

What Are the Different Grades of Stainless Steel?

Steel can be used in a wide variety of grade levels, ranging from 200 to 500, which merges austenitic, ferritic, and martensitic types. These types have further subdivisions that allow stainless steel to be used in many applications, which makes further classification remarkably useful.

- The common grades of austenitic steel, namely 200 and 300 series, have temperature resistance. 304 and 316 stainless steel are one of the more common types. 316 is commonly preferred over 304 because it’s suitable for more hostile environments, usually in the marine industry.

- Known for good corrosion resistance, Grade 430 ferittic also passes as a magnetic material. Having more use in cars and some industrial products makes this a stample in form of grade 400 designation.

- With the ability to become tools and objects meant for harsh usage martensite also have an added advantage of durability and corrosion resistance. Grade 410 is the one most frequently used to create such products.

- This pair list combines properties of iron and ferritic steel alloys, such as soft ferritic or martensitic resin, which assist in providing a guarantee for extreme endurance against corrosion. Methane and oil ducts in chemical plants tend to use this grade daily.

- Designed specially with an oil coated resin are the PH grades whose main purpose is to provide resistance against harsh conditions. Strenght becomes a common material gain while being used in extreme environment such as in spacecrafts or other costly projects.

Stainless steel proves to be adjustable to suit any purpose and range provided which targets multiple uses and interest over some time due to it’s flexible demeanor suited to the targeted grade. With every grade ensuring its own durability when it comes to harsh surroundings, the uses for this metal become endless.

An Overview of Austenitic Stainless Steel Grades

Austenitic stainless steels are the most common type of stainless steel because of the excellent property it holds in terms of corrosion. This type of stainless steel is known for being non-magnetic and highly ductile. The primary grades in this category include 304 and 316, which are differentiated by their chromium and nickel content. Grade 304 is known as the standard type of stainless steel, which has immense application for kitchen equipment, architectural work, infrastructure and food processing due to its unparalleled hardness and corrosion resistance. Grade 316 is further enhanced with molybdenum, which makes it incredibly resistant to chlorides, making the grade ideal for marine and chemical industries.

Also noteworthy are austenitic grades 310 with excellent high-temperature properties and 321, which adds titanium for greater resistance to intergranular corrosion. The wide range of applications for medical devices, construction, and many other fields makes austenitic stainless steels highly valued due to their versatility. The broad spectrum of conditions they can endure cements their status as a vital material across numerous sectors.

Understanding Martensitic Stainless Steel and Its Applications

Martensitic stainless steel stands out as a subclass owing to its exceptional strength, hardness, and wear resistance resulting from the application of a specific heat treatment. Stainless steels. Unlike austenitic types, the martensitic grades, such as 410 and 420, are magnetic, have lower corrosion resistance, but remarkable mechanical properties. Durable surgical instruments, cutlery, and turbine blades where edge retention is critical can be made of martensitic stainless steel owing to these properties. More often than not, a precise balance of heat treatment and alloy composition needs to be decided to meet performance targets set for industrial or medical applications.

Characteristics of Ferritic Stainless Steel

Ferritic stainless steel accounts for a range of chromium from 10.5% to 30%, but contains little to no nickel. It is associated with the body-centered cubic (BCC) crystal structure and has an impressive ability to resist corrosive materials, especially chlorides. Due to these structures, ferritic stainless steels, unlike other steels, have turned out to be magnetic. Their conductivity is also high, which positions them well on the market for usage in automotive exhaust systems, industrial equipment, and for architectural purposes.

Among the key technical parameters of ferritic stainless steel one can distinguish:

- Magnetic ferritic stainless steels with chromium nitride As a defining mark distinguishing ferritic from other stainless steels, this material possesses high corrosion and oxidation resistance with a chromium content of 10.5% to 30%.

- 0.5% or lower As compared to austenitic steels, this material has lower nickel content, ensuring lower alloying and manufacturing shrimp costs.

- Yield strength This parameter is determined by specific grading and usually lies between 275 to 450 MPa.

- Operating temperature Chromium nitride construction can withstand continuous exposure up to 750°F (400°C) and 300°C (572°F) for non-continuous exposure.

- Magnetic properties Unlike other classes of stainless steel, this material is fully magnetic.

- Weldability. Though some alloys prominently stress lower weldability than their austenitic counterparts, the advanced modern techniques available ensure that selective alloys have improved weld characteristics.

They do also possess low intergral strength during high temperatures, making them susceptible to grain growth with welding, thus requiring stringent process control for certain applications.

How Do Heat Treatment and Alloy Composition Affect Stainless Steel Hardness?

The procedures of heat treatment and alloying directly influence the hardness of stainless steel. Heat treatments like quenching and tempering improve the mechanical properties of the steel’s microstructure. For instance, martensitic stainless steels exhibit remarkable hardness as a result of tailored heat treatment techniques. Also, carbon, chromium, molybdenum, and nickel profoundly impact the hardness due to their influence on the formation of carbides, grain size, and the strength of the stainless steel matrix. A specific approach to heat treatment and alloying should correspond to the optimal level of hardness, ductility, and corrosion resistance needed for the particular use case.

The Impact of Heat Treatment on Stainless Steel Durability

Heat treatment certainly adds to the durability of stainless steel, as it transforms the steel’s microstructure, which leads to desirable mechanical properties. Processes like annealing, quenching, and tempering are used to refine grain structure, relieve internal stress, and enhance a material’s hardness or toughness. For example, the martensitic stainless steels benefit greatly from increased strength and wear resistance due to hardening and tempering.

Some of the Key technical factors are heating temperature, cooling rate, and holding time. Parameters such as annealing austenitic stainless steel require the temperature to be set at 1,900°F to 2,100°F (1,040°C to 1,150°C) followed by rapid cooling to retain corrosion resistance. Similarly, martensitic stainless steel is tempered after being hardened at 950°F to 1,150°F (510°C to 620°C), and then tempered depending on the required hardness and toughness. Control of these factors enables the stainless steel to maintain optimal mechanical performance while ensuring tailored longevity for a specific application.

How Alloying Elements Influence Hardness

Alloying elements significanlty increase the hardness of steel by changing its microstructure and mechanical properties. Important alloying elements like carbon, chromium, manganese, molybdenum, and vanadium are crucial as they aid in the formation of hard phases like martensite and carbide precipitation which contribute to impacts of hardness.

- Carbon (C): Carbon increases the hardness of steel the most since it is dicreeable as iron carbide (Fe3C). It strengthens the iron through solid solution strengthening and precipitation hardeining. Carbon content increases hardness, with high carbon steels being at 0.8% carbon for maximal hardness.

- Chromium (Cr): Chromium increases the hardenability of steel disks at higher temeperatures as austenite turns into pearlite during cooling. Heady wear resistant chromium carbide is also formed which provides superior protection also. Different stainless steel varieties contain chromium from 10.5% to 18% for optimal hardness and corrosion resistance.

- Manganese (Mn): Hardenability and toughness increases with addition of up to 1% manganese as it helps reduce brittleness as well as equalize the level of hardness across the grain boundaries. Comended dosage is 0.5% to 2%.

- Molybdenum (Mo): Molybdenum helps keep steel’s strength at higher temperatures while preventing it from becoming brittle and tempering softened steel during heat treatment. Different grades of steel require 0.2% to 1% molybdenum.

- Vanadium (V): Vanadium enhances fine scale microstructure by helping with grain refinement, which improves hardness and toughness. The vanadium carbides are among the most hardest and add to wear resistance. Vanadium amounts are usually between 0.05% and 0.5%.

Metallurgists balance different alloying elements, using precision to meet specific needs of varying applications in automotive, aerospace, or industrial machining tools, tailoring the hardness properties to the needs of the customer.

The Effects of Cold Work on Stainless Steel Hardness

Cold working boosts the hardness of stainless steel by changing its crystal structure. The mechanical stress experienced by a grain during rolling, hammering, or similar processes leads to its plastic deformation. This results in further refinement of the grain structure and increased dislocation density, which hinders subsequent dislocation movements, toughening the material. In my opinion, this helps manufacturers achieve the required hardness and strength without having to change the chemical composition of the steel, showcasing its increased versatility for use in construction or even medical equipment where durability is often crucial.

How Does Stainless Steel’s Corrosion Resistance Relate to Its Hardness?

The chromium found in stainless steel aids in improving its corrosion resistance. It fortifies a passive oxide layer, which helps in rust prevention. On the other hand, steel’s microstructure gives it its hardness, which can be improved through working hardening or heat treatment procedures. While it is true that increasing hardness doesn’t always help with improving corrosion resistance, certain treatment methods, do as precipitation hardening, allow dual property improvement. This makes stainless steel a preferred option in sensitive environments where durability and degradation resistance is crucial.

The Balance Between Hardness and Corrosion Resistance

In engineering applications involving stainless steel, a martensitic type like grade 420 or 440C, which contains a higher amount of carbon, can be used for cutting tools due to the ability 440C possesses to endure moderate corrosion. This type of stainless steel enables maximum hardness of about 600 HV. Alternatively, Austenitic steels like 304 and 316 would not perform well in these applications due to having lower hardness, ranging between 150-200 HV due to extreme heat treatment, but they are much better at corrosion resistance due to high content of nickel and chromium.

If both properties are needed in an alloy, grade 2205 will come out on top as it is a duplex stainless steel alloy which achieves the tremendous strength values of 250-300 HV while retaining good stregnth in corrosion resistive environments. Other examples are 17-4 PH which is a precipitation hardening steel that can be heat treated without losing good resistance to corrosive agents resulting in high hardness of 350-450 HV. Using solution annealing alongside quenching and aging allows attaining the needed corrosion resistance and desired strength.

How Chromium and Molybdenum Enhance Corrosion Resistance

The addition of chromium and molybdenum increases the corrosion resistance of steel because they help in the formation of a passive protective oxide layer on its surface. Passive layers depend on the environment and can dissolve if the environment changes. In the case of steel, oxidation will most likely happen. If oxidation happens, chromium combines with oxygen and forms an oxide, which is a protective barrier to corrosion. Molybdenum, on the other hand, enhances the resistance of localized corrosion, such as pitting and crevice corrosion due to chloride and acid-containing regions. Both elements maintain the material’s integrity and reliability under harsh conditions.

What Are the Common Applications of Various Stainless Steel Grades?

Employers in numerous industries find stainless steel useful because of its strength, versatility, and ability to resist corrosion. Kitchen utensils, appliances, food processing machinery, and some architectural features make use of austenitic stainless steels, such as grade 304, due to its excellent corrosion resistance and ease of fabrication. Moderately ferrous grades, like 430, are used for consumer-grade home appliances and automotive trim because of their mediocre corrosion-resistant properties paired with lower pricing. Cutlery, surgical instruments, and tools that need significant strength and toughness put the martensitic classed steels to use, exemplified by 410. For everything chemical processing related, marine structurals, and oil and gas, duplex stainless steel shows its true prowess with unparalleled resistance to stress corrosion cracking. Each grade is tailored per cryptic requirements to sustain various environments.

Uses of 304 Stainless Steel in Industry

304 stainless steel is arguably one of the most versatile and widely used grades of stainless steel because of its degree of corrosion resistance, durability and ease of fabrication. Its major applications include:

- Food and Beverage Sector: Due to 304’s excellent resistance properties to acids and alkali use environments, it is used in food processing machinery, kitchen equipment, storage tanks, and piping.

- Construction and Architecture: 304 stainless steel is used in structural components, roofing, handrails, facades etc., due to its strength and polished look in modern architecture

- Medical industry: Surgical instruments, medical devices and laboratory apparatus require non reactive and easy to clean surfaces and therefore made out of 304 stainless steel.

- Chemical Processing Industry: In comparison to other austenitic grades,304 resists corrosion better. Therefore, the alloy is used in chemical containers, heat exchangers, piping, and joints subjected to low-concentration acids or high humidity.

- Transportation and Automotive: In brackets and parts trim, it is utilized in the exhaustsystemGiven its durability and temperature resistance, it is used.

- Domestic Goods: It is also popularly used in cookware, knives, forks, spoons, and sinks because of its strength and aesthetic appeal.

Technical Parameters of 304 Stainless Steel

For your convenience, below are the most common stainless steel 304 grade specifications.

- Chemical Composition:

- Chromium(Cr) – 18.0 – 20.0 %

- Nickel(Ni) – 8.0 – 10.5 %

- Carbon (C) ≤ 0.08 %

- Manganese(Mn)≤ 2.0 %

- Silicon(Si) ≤ 0.75 %

- Phosphorus (p) ≤ 0.045 %

- Sulfur (S) ≤ 0.03 %

- Mechanical Properties:

- Tensile Strength: >= 515 MPa

- Yield Point (0.2% offset): >= 205 MPa

- Elongation (50 mm) >= 40 %

- Hardness (Brinell): <= 201 HBW

- Thermal Properties:

- Melting range: 1400 – 1450°C (2552 – 2642°F)

- Thermal conductivity (at 100°C): ~ 16.3 W/m·K

Due to the properties of 304 stainless steel along with its relative abundance compared to other materials, it has applications in a wide range of industries.

The Role of 316 Stainless Steel in Marine Environments

Due to its unparalleled resistance to rust, especially from chloride and seawater, 316 stainless steel is pivotal in marine settings. 316 has higher content of molybdenum than 304 stainless steel, making it ideal for applications such as boat fittings, underwater equipment, and offshore platforms because it resists pitting and crevice corrosion. Even in harsh conditions, they need not worry about the life or reliability of the devices, nor the maintenance intervals, as they are ensured durability and resilience.

Applications of Precipitation Hardening Stainless Steels

In so many industries that require fabrication, corrosion-resistant and super-strength materials like hardenable precipitate stainless steels stand out because of their versatility. These materials show remarkable properties in mechanical loading facing aerospace, marine, chemical processing, and even medical engineering.

- Aerospace Components

For fasteners, turbine blades and structural components, the aviation industry heavily relies on hardenable precipitate stainless steels. Grades such as 17-4PH are especially popular as well due to their unparalleled tensile strength up to 1310MPa and strong stress corrosion cracking resistance for high-temperature operating regions.

- Marine Applications

In marine environments, especially when in contact with saltwater, this kind of steels show commendable resistance to corrosion when used for propeller shafts, pumps and valve components where pitting and crevice corrosion is a concern.

- Chemical Processing Equipment

Hardenable precipitate steels are used in harsh environments like chemical reactors and heat exchangers where the subhigh pressures and aggressive corrosive nature of elements clash at the same time. 15- 5PH is an example that provides mechanical integrity and reliable corrosion resistance.

- Medical Devices

The hardness and wear-resistance of these steels make them ideal for use in surgical and dental tools as well as orthopedic implants. On top of that, these tools require robust mechanical cleaning and biocompatible materials for sterilization, which these alloys offer.

- Oil and Gas Industry

Components such as downhole tools and pump shafts require specialized materials capable of enduring harsh temperatures, pressures, and corrosion. For intense applications, 13-8Mo is a precipitation hardening grade that offers high yield strength, excellent yield strength, and an unparalleled strength of up to 1150 MPa.

Precipitation hardening stainless steels exhibit unrivaled and unmatched properties which enables them to withstand the demands of any industry that requires steadfastness and multi-functionality.

References

- Explain the Hardness of Stainless Steel & Hardness Chart – A detailed explanation of stainless steel hardness and its grades.

- Stainless Steel Grade Chart – A comprehensive chart detailing stainless steel grades and their properties.

- Understanding the Hardness of Stainless Steel: Properties – A blog post explaining the concept of stainless steel hardness and its implications.

Frequently Asked Questions (FAQ)

Q: What is the hardness of stainless steel?

A: The hardness of stainless steel varies depending on the grade and treatment. It can range from relatively soft to very hard, especially when heat treated. For example, 420 stainless steel, which is a high carbon steel, can achieve high hardness and wear resistance after proper heat treatment.

Q: How does the carbon content affect the hardness of stainless steel?

A: The carbon content in stainless steel significantly influences its hardness and strength. Higher carbon content typically results in higher hardness and tensile strength, but it may also reduce toughness and increase brittleness.

Q: What are the properties of 420 stainless steel?

A: 420 stainless steel is a high-carbon steel known for its high hardness, good corrosion resistance, and excellent wear resistance. It is often used in cutlery, surgical instruments, and tools. It can be further enhanced through heat treatment to improve hardness and toughness.

Q: Can stainless steel be welded?

A: Yes, stainless steel can be welded, although different types of stainless steel require specific welding techniques. Austenitic stainless steels, like type 304, are generally more weldable compared to others due to their high chromium and nickel content, which provide good weldability and resistance to corrosion.

Q: What is the significance of chromium content in stainless steel?

A: Chromium content is crucial in stainless steel as it forms a passive layer of chromium oxide on the surface, providing resistance to corrosion and oxidation. Typically, a minimum of 10.5% chromium is needed for a steel to be considered stainless.

Q: How does the yield strength of stainless steel compare to ordinary steel?

A: The yield strength of stainless steel often exceeds that of ordinary steel due to its alloy composition and heat treatment capabilities. For instance, duplex stainless steel has a higher yield strength compared to mild steel, making it suitable for applications requiring high strength and resistance to corrosion.

Q: What are the differences between 304 and 316 stainless steel?

A: Both 304 and 316 are austenitic stainless steels known for their corrosion resistance. However, 316 contains molybdenum, which enhances its resistance to pitting and crevice corrosion in chloride environments. This makes 316 more suitable for marine and chemical applications compared to 304.

Q: Can stainless steel be annealed to improve its properties?

A: Yes, stainless steel can be annealed to relieve stresses, soften the material, and enhance its ductility and toughness. Annealing typically involves heating the steel to a specific temperature and then cooling it at a controlled rate.

Q: What role does titanium play in stainless steel alloys?

A: Titanium is added to some stainless steel alloys to stabilize the structure and prevent the formation of chromium carbides, which can lead to intergranular corrosion. It helps in maintaining the corrosion resistance of stainless steel at high temperatures.