The development of high-strength low-alloy steel has transformed age-old industrial practices with its unique properties of toughness, ductility, and strength. High-strength low-alloy steel grades include many examples, but HR420LA coil is among them, eminent for its characteristics as well as its numerous uses. Whether automotive companies seek parts that are not heavy but also strong, or manufacturing enterprises require these resistant steels, this class of steels is highly versatile. This discussion is geared towards an analytical evaluation of the characteristics, usage, and advantages of HSLA HR420LA coil, to understand why it is most preferred in contemporary design and manufacturing. Continue reading to discover how this new reticulating agent facilitates industrial evolution.

Understanding HSLA HR420LA Steel

HSLA HR 420 LA steel is a low-alloy, high-strength kind of steel, which combines an excellent weight-to-strength ratio with even better formability. It has been developed particularly for those applications where there is a need for allocations and allocations, and for more values to be of importance these days. Considerable stress, especially impact, is resisted by this steel and is therefore valuable, for example, to industries such as automotive, building, and manufacturing. Moreover, the steel design ensures easy machining processes, such as welding or cutting, without compromising the steel’s stability. For these (and other) reasons, most engineers or manufacturing firms who use advanced materials will choose the HSLA HR420LA as a viable option.

What is HSLA Steel?

The HSLA or Hr420la coil is a special cone alloy steel with improved mechanical properties and increased resistance to erosion compared to carbon steel, due to the inclusion of limited amounts of chromium, nickel, manganese, or other alloying elements.

Chemical Composition of HR420LA

HSLA HR420LA is a high-strength low-alloy steel designed to offer optimal mechanical properties as well as corrosion resistance. It comprises alloying constituents in regulated proportions to meet the requirements for its properties. Thorough specification of its chemical composition is outlined in the table below:

- C= carbon ≤ 0.08%

- Mn = manganese ≤ 1.30%

- P= phosphorus ≤ 0.025%

- S= sulfur ≤ 0.010%

- Si= silicon ≤ 0.50%

- Ti= titanium ≤ 0.10%

- Nb= niobium ≤ 0.09%

- Al= aluminum ≥0.015%

All these elements, when combined, contribute to the desired properties of HR420LA, such as high yield strength, formability, and weldability. The reduction of weldability due to low carbon content is enhanced by alloying with precious metals such as titanium and niobium, which promote grain refinement and precipitation hardening, respectively, thereby improving the steel’s overall mechanical characteristics.

Such a composition makes HR420LA particularly applicable to automotive structural components, where inherent stiffness and strength-to-weight ratios, as well as fatigue resistance, are very essential.

Mechanical Properties and Yield Strength

Given all the above-mentioned mechanical properties, HR420LA steel is a high-strength low-alloy steel sheet for automobiles that should meet exacting requirements. The details of the functional properties of HR420LA are provided below.

- The elastic limit of wear is in the range of 420 – 520 MPa, which enables high strain resistance.

- The ultimate tensile strength, as a rule, is typically more than 500 MPa, which is necessary for achieving good load handling performance.

- An extension at rupture of 18-25% is provided to ensure good workability and ductility.

- The hardness index is at a hypereutectic level, amounting to about 140-180 HBW, which means it is tough and deus ex machina.

- Welding is considered an advanced international technology with a minimum carbon content, and therefore has the capability for significant usage in manufacturing, where rechargeable features requiring extensive welding are taken into account.

Such favorable mechanical properties of HR 420 LA stainless steel make it one of the best steel grades for the KU and HSWA. They are found in the automotive industry as well as in constructional plants and structures, among others.

Applications of HSLA HR420LA Coils

HSLA HR420LA coil is ideal for structures that operate under high loads while maintaining a slim profile towards light weight. Due to the properties above, the applications of such steel components will not be limited to:

- First, the automotive sector: It provides a good strength-to-weight ratio and ease of welding, making it efficient for the fabrication of supporting structures and parts, including frames.

- Secondly, the construction industry: Effectively applicable in reinforcing buildings, improving their strength and elasticity.

- And finally, heavy structures: All these structures where components are machine parts and beams are applicable.

In most cases, their use is determined by the fact that the material can operate without failure in relatively harsh conditions.

Automotive Industry Applications

With all the advances in the automobile industry, high-strength steel has emerged as a game changer. Not only are the cars chilled due to comfort and luxury, but they also offer safety, performance, and efficiency. Below are five key applications of high-strength steel within the sector:

a. Structural systems: The use of high-strength steel in the framework and chassis of lorries is relatively widespread to enhance crashworthiness and structural durability. An increase in the safety of passengers’ buckets is promoted while reducing the weight.

b. Doors, bonnet, and roof panels: High-strength steel is used in these panels in doors, bonnets, and roofs since they require thick and heavy panels to increase their durability. Hence, mileage improvements in fuel usage help in minimizing pollution levels.

c. Suspension Designs: Some aftermarket parts, such as the moot arm or wishbone and four-wheel bobtail, can be manufactured from strong and fatigue-resistant materials, which ensures they will serve for a very long time even in active load environments.

d. Braves: In critical areas such as door guard beams and roof stringers, high-strength steel is very effective, due to its energy-absorbing characteristics, when such areas are hit or attacked.

e. Overhaul Parts: Gears, Pistons, and other’ Compromised’ Engine Parts use this material because of the need for Strength, Accuracy, and Functionality in Stressful Situations.

In the above cases, strong steels provide designers with the opportunity to address the advanced safety needs of the vehicle and meet more stringent environmental demands, while also preserving the possibilities and potential of modern transportation.

Other Industrial Applications

High tensile steel is popular in many sectors, especially the construction industry, due to its numerous beneficial properties. These include its toughness, light weight, and economy. Here are some of the sectors:

- Building and Construction: In civil engineering, high-tensile steel bars are oval and are used in buildings, bridges, or other structural works. It is an essential element of contemporary designs for handling high stress in many cases, as it has less weight compared to other materials. Studies show that the use of high-tensile steel can reduce construction material usage by 30%.

- Power and Energy: Kalapana and blades, towers, are some of the wind turbines’ components that contain high-tension steel and can withstand a wide range of weather conditions and stress. It is also used in the construction of pipes for transporting oil and gas due to its corrosion and pressure resistance.

- Construction Machines and Equipment: Heavy nacelles and jib cranes, along with loaders and trucks, which are heavy machines, utilize high-tension steel during manufacture. The loads these machines perform require high performance for safety and proper functioning.

- Scheduled: Marine ships that sail longer distances with flexible seasonal weather variations, as well as offshore structures, are fabricated with relatively high strain strength. This aids in enhancing the lifespan and fuel efficiency as the weight is decreased.

- Aeronautical: In aviation engineering, high-tensile steel is often used in the production of various aircraft components, including undercarriages and bolts. Such components need assurance of high strength, accuracy, and resistance to fatigue forces. Thereby ensuring optimal performance and protection of the aircraft in harsh conditions.

Benefits of Using HSLA Steel in Manufacturing

| Key Benefit | Description |

|---|---|

| High Strength-to-Weight Ratio | Strong yet lightweight for structural use |

| Improved Corrosion Resistance | Resists rust and environmental damage |

| Enhanced Weldability | Easy to weld for diverse applications |

| Better Formability | Can be shaped without cracking |

| Cost-Effective | Reduces material and fabrication costs |

| Increased Durability | Withstands wear, stress, and impact |

| Lightweight Design | Reduces transportation and installation costs |

| Customizable Properties | Tailored for specific strength or flexibility |

| Energy Efficiency | Lighter components improve fuel efficiency |

| Long Lifespan | Durable in harsh environments |

Manufacturing Processes of HR420LA Coils

hsla hr420la coil manufacturing process comprises of the following steps, each executed with precision for specific purposes:

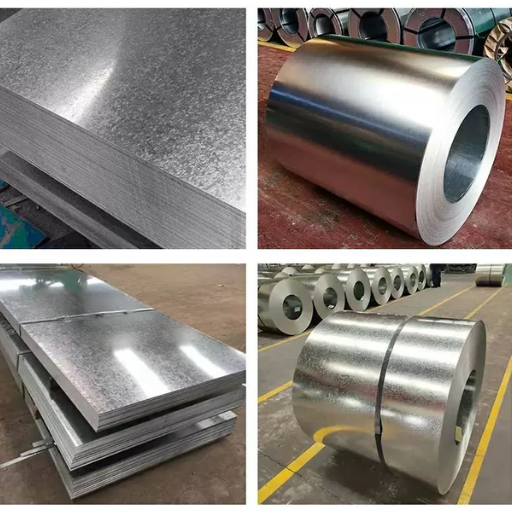

- Hot Rolling: The steel slab is heated to a high temperature and pressed between rollers to reach the thickness and width specifications of the coil. This helps to improve the workability of the material as well as its strength.

- Pickling: The hot-rolled steel is pickled to remove oxides and foreign impurities from its surface, thereby achieving a smooth finish.

- Cold Rolling (where necessary): If required, the steel is cold rolled to enhance its mechanical properties, surface finish, and uniformity.

- Annealing: This step involves annealing the coils to relieve the stresses present in the material, making it more ductile and easier to form.

- Surface Coating if needed: This is done by applying an anti-corrosive coating on steel in order to increase its service life.

Each of these steps is carefully executed to ensure that the product performs as expected while meeting or exceeding existing industry durability standards.

Hot Rolled vs. Cold Rolled Processes

| Parameter | Hot Rolled | Cold Rolled |

|---|---|---|

| Processing Temperature | Appliances, aerospace, and metal furniture | Above the recrystallization temperature |

| Surface Finish | Rough, scaly | Smooth, polished |

| Strength | Lower strength | Higher strength |

| Dimensional Accuracy | Less precise | Highly precise |

| Cost | Cheaper | More expensive |

| Applications | Structural components, railroad tracks | Appliances, aerospace, metal furniture |

| Workability | Easier to shape | Harder to shape |

| Internal Stress | Minimal | Higher |

| Appearance | Less aesthetic | Aesthetic and uniform |

| Common Uses | I-beams, sheet metal | Automotive parts, precision components |

Surface Treatment and Coating Options

In the fabrication of steel, surface treatment and coating are crucial factors that enhance the durability of the products/fracture toughness of the material, resistance to corrosion, and steel aesthetics. All these processes, including stones, are developed to ensure that the metal can be kept repeatable in harsh conditions and comply with the design specifications of each industry. Some of the most popular surface and film-forming processes are discussed below:

- Galvanization:

- Description: Thin films of zinc, for instance, through processes such as hot-dip galvanizing or cold-dip galvanizing, are applied over the steel surfaces. This zinc oxidizes in preference to the steel, and hence a protective coating forms over the steel, preventing any iron-oxygen reactions.

- Use: Found in fabricated steel used/ applies in building/ construction, automobile product parts, and exterior projects.

- Fact: For hot-dip galvanised steel in appropriate conditions, the life expectancy will be improved by 20 to 40 years.

- Powder Coating

- Description: A dry powder is sprayed with a charged gun onto the steel surface, and after that, it is heated so that the powder can melt and form a hard, protective, durable, and decorative finish on the steel.

- Use: Found in home appliances, outdoor furniture, and even in industrial equipment.

- Fact: Powder coating forms a surface 10 times more resistant to wear and chipping than regular paint.

- Plating

- Description: Steel is submerged into a solution of electrolyte, while a thin layer of metal such as chrome, nickel or copper is placed on the surface.

- Use: Used to manufacture decor items, electrical equipment, and car components.

- Fact: Plated steel offers immensely greater resistance to wear and corrosion than unplated steel.

- Anodization

- Description: Enhancing the toughness of the oxide film on the surface of the steel can sometimes be done using anodizing, although it is mainly applied to aluminum surfaces.

- Use: Primarily intended for decorative purposes, as well as for construction purposes.

- Fact: Typically, anodized steel can last 3-5 times longer than plain steel.

- Oil or Wax Coating

- Description: It is a brief period coating applied to steel, of an oily or waxy nature, used to arrest corrosion of steel during storage or transportation.

- Use: It is prominently used in the manufacture of vehicle parts, the storage of steel coils, and the protection of machine parts awaiting machining.

- Fact: It has a short and limited protection capability, which ranges from weeks to several months, depending on the conditions of use.

The coatings and surface treatments presented here are essential for the adequate performance of steel in various applications, thereby extending the time and utility of the steel.

Quality Control and Tolerance Standards

Producing steel products that conform to their required quality specifications requires a commitment to detail and rigorous quality control. Tolerances are a crucial metric in production processes, which today rely on up-to-date technologies such as automated quality inspection systems and laser-based measurement equipment for control and alignment.

Major Quality Control Guidelines

- Dimensional Corrections: It is important to note that measurement of dimensions using devices with presented scale negativity in place will enable the observation of such deviations of steel parts from the object’s correct dimensions. The assumption is that the tolerance limits are primarily in the range of +/- 0.1 to +/- 0.5 mm, which largely depends on the field of application.

- Surface Condition: This is possible because a unit allows a significant amount of scratches, specifications, dents, and even some surface profiles. A frequent basis for units’ roughness is the arithmetic mean roughness, Ra, on the grounds of the finish specifications that the unit was required to meet in cases where polished steel is rated at less than, or equal to, 0.2 micron (Ra ≤ 0.2 µm).

- Material Properties Tests: With the development of spectrophotometric measurement, steel is presented in terms of its chemical composition, allowing for the use of determined levels stipulated in specified standards, as outlined in the ASTM, ISO, or EN standards.

- Proof Test: When tensile testing instruments yield the result for the force applied to the material before fracture of a sample, efforts are made to achieve a certain amount of the most critical strengths from the destruction plantations.

- Screened Examination (NDT): Tools such as ultrasound and Mechanical (Nimbus) testing, along with novel techniques, enable the repair of materials without affecting their structure.

Products Tolerance Information:

- Planarity Tolerance: This is applied to these HSLAS, HR420LAS, coils, etc., and is set within a particular range, 0.15% to 0.3% Flat level, which depends on the thickness, length, or other physical properties related to the specific shape.

- Height Variation: For hot rolled steel, the thickness variation is usually not more than (±)0.8mm, but in tight tolerances, such as cold rolled steel, it is nearly always not more than (±)0.25mm.

- Bowing – Removes curvature in the planer: Variations in most other structures will not exceed 1mm per meter of straightness deviation.

Due to the diverse applications of steel, including civil construction, automobiles, aircraft, and energy, well-defined manufacturing procedures are necessary to ensure adherence to the quality control measures and tolerances in the production process. Thus, steel producers practice or fulfill these demands.

Comparative Analysis of HSLA HR420LA with Other Steel Types

| Parameter | HSLA HR420LA | Carbon Steel | Stainless Steel | Dual Phase Steel |

|---|---|---|---|---|

| Yield Strength | ≥ 420 MPa | 250-400 MPa | 200-300 MPa | 500-700 MPa |

| Tensile Strength | 480-620 MPa | 400-550 MPa | 500-750 MPa | 600-1000 MPa |

| Ductility | High | Moderate | Low | Moderate |

| Corrosion Resistance | Moderate | Low | High | Moderate |

| Formability | Excellent | Good | Poor | Good |

| Weldability | Excellent | Good | Moderate | Good |

| Cost | Moderate | Low | High | Moderate |

| Applications | Automotive, structural components | General construction, pipelines | Kitchenware, medical equipment | Automotive, crash-resistant parts |

| Weight Efficiency | High strength-to-weight ratio | Moderate | Low | High |

| Surface Finish | Smooth, suitable for coating | Rough | Polished | Smooth |

Equivalent Grades and Comparisons

| Parameter | HSLA HR420LA | Equivalent Grade (JIS) | Equivalent Grade (ASTM) | Equivalent Grade (DIN/EN) |

|---|---|---|---|---|

| Standard | VDA 239-100 | SAPH440 | A1011 HSLAS-F Grade 50 | S420MC |

| Yield Strength | ≥ 420 MPa | ≥ 420 MPa | ≥ 420 MPa | ≥ 420 MPa |

| Tensile Strength | 480-620 MPa | 480-620 MPa | 480-620 MPa | 480-620 MPa |

| Elongation | ≥ 16% | ≥ 16% | ≥ 16% | ≥ 16% |

| Applications | Automotive, structural components | Automotive, structural components | Automotive, structural components | Automotive, structural components |

| Formability | Excellent | Excellent | Excellent | Excellent |

| Weldability | Excellent | Excellent | Excellent | Excellent |

Advantages Over Standard Steel Grades

- Higher Strength-Weight Ratio

A better strength–to–weight ratio is offered by advanced steels than even ordinary steel. Owing to this, they are highly suitable for designs where weight considerations are critical, such as in the automotive and aerospace industries.

- Better Weldability

As such, there are more working possibilities in terms of manufacturing processes associated with the above-mentioned steel grades because they are easier to weld, resulting in strong sections with minimal risk of problems.

- Rust Resistance

Some advanced steel grades exhibit greater rust resistance, and thus, the layers of protection for products in wet, chemically active, or other aggressive conditions increase.

- Better Surface Finishing

In addition to enhancing the overall surface appearance, these types of steels remain applicable in a diverse range of surface treatment processes, as the surface finishing is, in most cases, significantly smoother.

- Reduction of Costs on Materials for Application

In terms of the cost of raw materials, although HSLA HR420LA coil steel is slightly more expensive, the reduction in unnecessary material usage is sufficient to offset the overall costs over time.

Performance in Different Applications

Advanced high-strength steel enables manufacturers to achieve superior mechanical performance and design for specific purposes across various industries. For instance, in the automotive industry, the widespread use of higher-strength steels (HSS) is employed to promote safer and lighter vehicles. Research on the lightweight design of cars suggests that using AHSS can reduce a vehicle’s weight by 25%, thereby improving its fuel economy and CO2 emissions. It aligns with global strategies that involve more stringent emission rules, such as the European Green Deal and the American CAFE standard.

Likewise, in the construction industry, due to their enhanced capacity to support loads and durability, greater amounts of strength are achieved through the use of constructional steels for structural members. Using these types of materials has enhanced the capacity of civil engineers to produce load-carrying, stable designs of structures. For example, building with weathering steel is approximately 25% cheaper than standard carbon steel, due to the minimal maintenance required for the bridges over their service periods.

Furthermore, tools and heavy equipment structures have an extended lifespan thanks to wear-resistant steel classes. Descriptive analyses indicate that wear-resistant steel components reduce downtime by approximately thirty percent, primarily due to improvements in performance in industries such as agriculture and mining. The use of such improved materials is a key element in efforts to meet the growing needs for efficiency and sustainability in all sectors.

Market Trends for HSLA HR420LA Steel

The demand from the automotive, construction, and industrial sectors has steadily driven market demand for HSLA HR420LA coil. In this context, the strength-to-weight ratio of the material is among the key factors driving demand increase, as currently, industrial designs, such as lightweight and fuel-efficient ones, are highly sought after. The regional ability to grow is particularly high in the Asia-Pacific region, owing to rapid industrial development and infrastructure expansion. Additionally, more and more environmentally oriented companies are being drawn to the use of HSLA steels, particularly with the inclusion of HR420LA, as it is a sophisticated method of ensuring load-carrying components are free from undue wastage.

Current Demand in the Automotive Sector

Companies in the vehicle industry produce HSLA HR420LA coil because vehicles are highly sought after for their lightweight design, high fuel efficiency, and performance attributes, all without compromising safety aspects. These materials are required by car makers as they fit in high expectations regarding strength and durability, implying that the raw materials are less confined by regulations such as emissions. Additionally, the availability of such materials is enhanced by the fact that there is widespread activity towards going gree,n and in return, the use of HSLA steel ensures material efficiency in manufacturing processes and makes lighter vehicles as well.

Future Market Projections

Over the next ten years, significant growth is anticipated in the global market for High-Strength Low-Alloy (HSLA) steels. Those in the industry are saying that the HSLA steel markets will be worth, with sales increasing at a compound annual growth rate of about six to eight percent from 2023 up until 2030. The increase can largely be attributed in part to higher consumption by the automotive industry; the energy and construction industries also play a part in the prospects for growth, utilizing HSLA steels.

The automotive line is expected to employ more HSLA steels as the enforcement of EVs and mileage standards takes effect, forcing the transportation industry to transition from older vehicles. Take, for instance, a case where manufacturers are believed to be set to reduce fleet weights by as much as 25 to 30 percent by 2030. In this time frame, the use of HSLA steels is best suited. Of particular note are regions in North America and Europe, owing to emission regulatory controls and the impact of global warming.

Moreover, the rapid urbanization experienced in countries such as India and China, among others, has heightened demand for more durable yet less environmentally harmful buildings. Due to their enhanced weight-to-strength ratio, many infrastructure elements, such as bridges and tall buildings, now often require the use of HSLA steels.

There is also measured optimism for the energy sector, especially considering the SSHLA grades, which are relevant to renewable energy’s wind turbines and offshore platforms. In 2022, BloombergNEF reported that clean energy investments exceeded $ 1 trillion, and that trend continues with the need for materials to support and sustain the technologies of renewable energy.

All of these elements combine to create a vibrant and growing HSLA HR420LA coil market, which provides numerous new applications for the material, including an emphasis on environmental sustainability.

Innovations in HSLA Steel Production

In my point of view, new developments in making HSLA steel HIGH STRENGTH LOW ALLOY are MARKETED and designed with a focus on science, more and less fit to weight ratio, increased resistance to corrosion, and lowered pollution levels. Techniques such as the addition of microalloyed elements like niobium and titanium, or advancements in thermomechanical processes, have greatly improved the performance of such materials. Furthermore, the use of more energy-efficient technologies (for example, those based on electric arc furnaces or with reduced CO2 emissions) demonstrates the necessary support for this aspect of the industry.

References

- ResearchGate:

- Title: Hot Rolling of HSLA Steels – a Review of Recent Studies

- URL: ResearchGate Article

- Description: A comprehensive review of HSLA steels, focusing on their properties, applications, and advancements in hot rolling processes.

- SSAB Official Website:

- Title: Docol® 420LA High Strength Low Alloy

- URL: SSAB Docol 420LA

- Description: Detailed information on Docol 420LA, a high-strength low-alloy steel, including its mechanical properties, applications, and certifications.

- SteelPro Group:

- Title: GMW3032M HR340LA Steel Coils Hot Rolled Steel

- URL: SteelPro Group

- Description: Insights into the technical specifications, manufacturing processes, and applications of HR340LA and related HSLA steel grades.

Frequently Asked Questions (FAQ)

What is HSLA HR420LA Steel?

HSLA HR420LA steel is a type of high-strength low-alloy steel known for its excellent weldability and corrosion resistance. It is often used in automotive applications and structural components due to its high tensile strength and minimal yield strength properties.

What are the mechanical properties of HR420LA Steel?

The mechanical properties of HR420LA steel include high tensile strength, toughness, and good fatigue strength. Its minimum yield strength typically exceeds 420 MPa, making it suitable for a variety of applications requiring high strength and durability.

How does the chemical composition of HSLA HR420LA affect its performance?

The chemical composition of HSLA HR420LA steel features a low carbon content and specific alloying elements, such as manganese and chromium, which enhance its mechanical properties, including strength levels and corrosion resistance. This composition makes it suitable for demanding automotive applications.

What is the significance of yield strength in HR420LA Steel?

Yield strength is a critical property that indicates the maximum stress that a material can withstand while still maintaining its shape. For HR420LA steel, a minimum yield strength of 420 MPa is crucial for ensuring structural integrity in automotive and other high-performance applications.

How does HSLA HR420LA Steel perform in terms of weldability?

HSLA HR420LA steel exhibits excellent weldability due to its low alloy content and specific chemical composition. This quality allows it to be easily welded without compromising its structural properties, making it ideal for automotive components and chassis applications.

What are the advantages of using cold-rolled HSLA Steel?

Cold-rolled HSLA steel offers enhanced surface quality and dimensional tolerances compared to hot-rolled steel. This results in improved formability, allowing for better performance in applications where precision is critical, such as the production of automotive parts.

Can HSLA HR420LA Steel be galvanized, and what are the benefits?

Yes, HSLA HR420LA steel can be galvanized, which provides an additional layer of corrosion resistance. Galvanization protects the steel from environmental degradation, making it suitable for long-term applications in automotive and structural settings.

What are the typical applications of HSLA HR420LA Steel?

HSLA HR420LA steel is used in a wide range of applications, particularly in the automotive industry for manufacturing chassis, structural components, and other automotive parts. Its high strength and excellent weldability make it a preferred choice for manufacturers aiming for durability and performance.

How does HSLA HR420LA compare to other high-strength steel grades?

HSLA HR420LA steel is comparable to other high-strength steel grades such as S420MC and Docol 420LA. However, it offers specific advantages in terms of weldability and corrosion resistance, making it particularly suitable for automotive applications where these properties are essential.