Get in touch with us

Leave a message

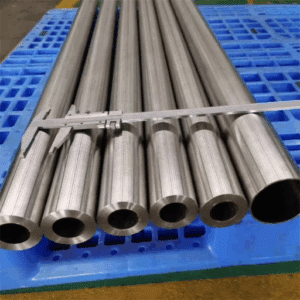

Our Chinese manufacturer specializes in Iron Nickel Alloy Pipes, a wonderful-quality invar material with low thermal expansion and good corrosion resistance. This type of nickel-iron alloy pipe or tube is one designed for particular applications where accurate dimensional stability is required. Due to the superior properties of nickel iron alloy, our Iron Nickel Alloy Tube is really an effective solution, considered to be reliable and steady under stringent environments by aerospace, electronics, and energy-based fields.

Iron Nickel Alloy Pipes are available in a range of standardized grades and classifications. Below are key specifications:

| Industry | Specific Uses | Grade Characteristics |

|---|---|---|

| Aerospace | Satellite frames, structural components | Low thermal expansion, high stability |

| Electronics | Magnetic shielding, circuit components | Excellent magnetic properties |

| Energy | Gas turbine components, heat exchangers | Corrosion resistance, high durability |

| Scientific Research | Optical systems, precision instruments | Dimensional stability, invar material |

| Telecommunications | Waveguide tubes, signal transmission pipes | High conductivity, nickel iron alloy |

A:

Primarily used in aerospace, electronics, and precision instruments for its low thermal expansion and stability.

A:

Invar tubes have lower thermal expansion and better corrosion resistance, ideal for precision applications.

A:

Approximately 1420–1450°C, depending on the alloy composition.

A:

Yes, TIG and laser welding are recommended for seamless integration and minimal distortion.

A:Aerospace, electronics, energy, and telecommunications due to its nickel iron alloy properties.

A:Contact our China manufacturer for tailored pricing and specifications.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.