Get in touch with us

Leave a message

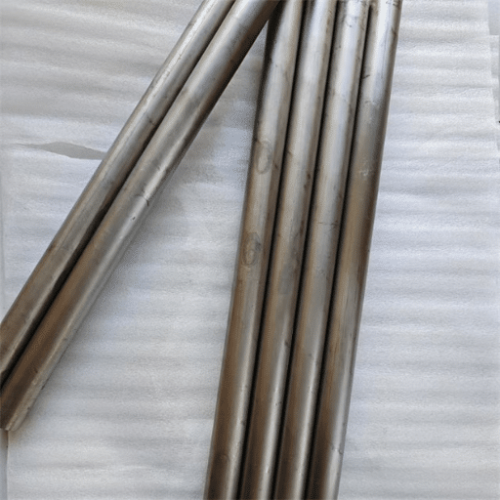

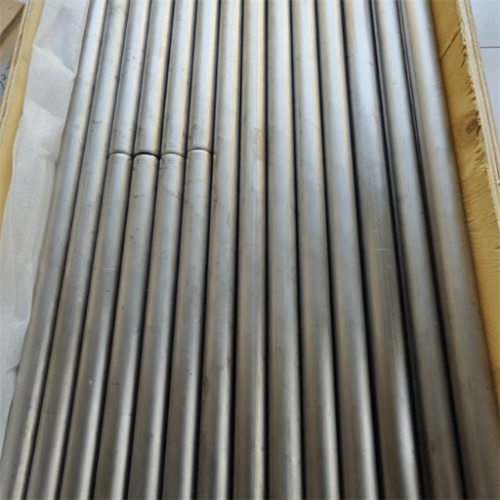

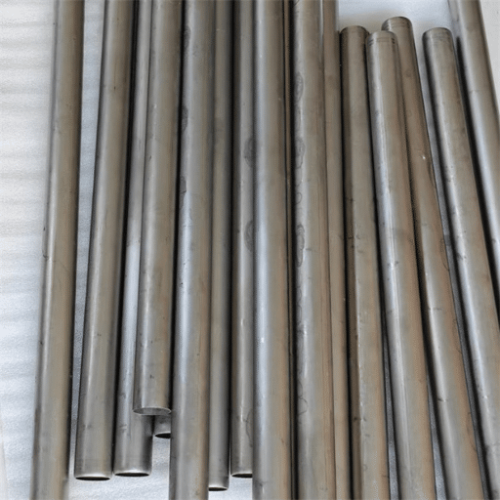

The 4j32a Iron Nickel Alloy Tube is a high-performance material designed for demanding industrial applications. This alloy is renowned for its excellent stability, low thermal expansion coefficient, and superior strength. It is widely used in sectors such as aerospace, electronics, and precision instruments, where precise dimensional stability is crucial.

Contact our sales team for a tailored quote on 4J32A Iron Nickel Alloy Tube. Competitive pricing and flexible terms for your project needs.

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 31.8 – 32.5 |

| Iron (Fe) | Balance |

| Cobalt (Co) | ≤ 0.5 |

| Manganese (Mn) | ≤ 0.5 |

| Silicon (Si) | ≤ 0.3 |

| Chromium (Cr) | ≤ 0.2 |

| Carbon (C) | ≤ 0.05 |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 490 MPa |

| Yield Strength | ≥ 240 MPa |

| Elongation (%) | ≥ 30 |

| Hardness | ≤ 200 HB |

The 4j32a Iron Nickel Alloy has superior chemical stability and is resistant to degradation in mild acids and alkaline environments. Limitations may arise in highly oxidizing mediums or extreme acidic environments.

| Environment | Resistance Rating |

|---|---|

| Atmospheric Environment | Excellent |

| Mild Acidic Solutions | Good |

| Alkaline Solutions | Good |

| Salt Spray | Moderate |

Contact us for detailed corrosion resistance data specific to your application.

4j32a Iron Nickel Alloy Tube is compatible with standard welding techniques such as TIG (Tungsten Inert Gas) welding and MIG (Metal Inert Gas) welding. Proper preheating and post-weld annealing are recommended to maintain optimized mechanical properties. Fabrication methods include bending, forming, and cutting based on project requireme

The 4j32a Iron Nickel Alloy Tube from this China manufacturer exceeded our expectations for satellite components. Its low thermal expansion is unmatched, and the custom lengths saved us time.

Mary W.

Aerospace Engineer

We’ve used invar material before, but the 4j32a alloy tube offers superior consistency. The polished finish and tight tolerances are perfect for our semiconductor applications.

Johnson K.

Electronics Manufacturer

This nickel iron alloy tube is a game-changer for our cryogenic systems. Excellent corrosion resistance and easy to machine, even for intricate designs.

Mike P.

Research Lab

A: It offers a significantly lower thermal expansion coefficient, making it ideal for precision applications.

A: Aerospace, electronics, and instrumentation industries are the primary beneficiaries.

A: Yes, finishes like polished or pickled can be tailored to your project needs.

A: The material has a melting point of approximately 1430°C.

A: Apart from tubes, it can be fabricated as rods, bars, or other custom shapes.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.