Get in touch with us

Leave a message

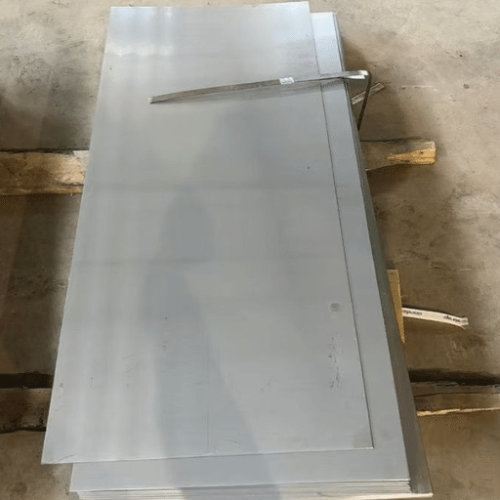

The 4j50 Iron Nickel Alloy Plate, widely known for its outstanding thermal expansion properties and excellent durability, serves as a prime choice for industries requiring stability in varying thermal environments. Manufactured to stringent standards, this alloy combines precision, reliability, and affordability, making it indispensable in aerospace, electronics, and telecommunications applications.

For pricing information on the 4j50 Iron Nickel Alloy Plate, contact us to receive a detailed quote. Pricing terms are available upon request, ensuring clear and competitive pricing tailored to your needs.

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 49.5-50.5 |

| lron (Fe) | Balance |

| Carbon (C) | ≤ 0.05 |

| Silicon (Si) | ≤ 0.30 |

| Manganese (Mn) | ≤ 0.50 |

| Sulfur (s) | ≤ 0.02 |

| Phosphorus (P) | ≤ 0.02 |

| Property | Value |

|---|---|

| Tensile Strength | 520-650 MPa |

| Yield Strength | 250-350 MPa |

| Elongation | ≥30% |

| Hardness (HB) | 140-180 |

| Modulus of Elasticity | 145 GPa |

The 4j50 Iron Nickel Alloy Plate exhibits excellent resistance to:

| Environment | Corrosion Resistance |

|---|---|

| Atmospheric (Dry) | Excellent |

| Atmospheric (Humid) | Very Good |

| Mild Chemical (Saltwater) | Good, with proper coating |

| Acidic (Dilute) | Moderate |

Contact us for detailed corrosion resistance data specific to your application.

The 4j50 Iron Nickel Alloy Plate from this China manufacturer exceeded our expectations for dimensional stability in satellite components.

Amber S.

Aerospace Technician

Reliable invar plate with excellent surface finish, perfect for our precision circuits.

Victor P.

Electronics Supplier

This nickel iron alloy’s low thermal expansion is ideal for our optical equipment.

Charlie Y.

Research Lab

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.

©2025 alloy-materials.com COPYRIGHT ALL RIGHT RESERVED.