Get in touch with us

Leave a message

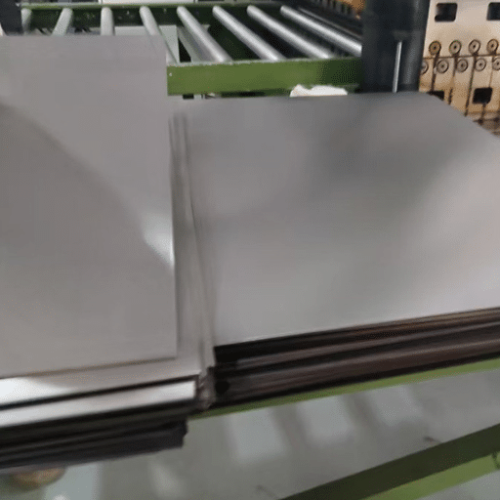

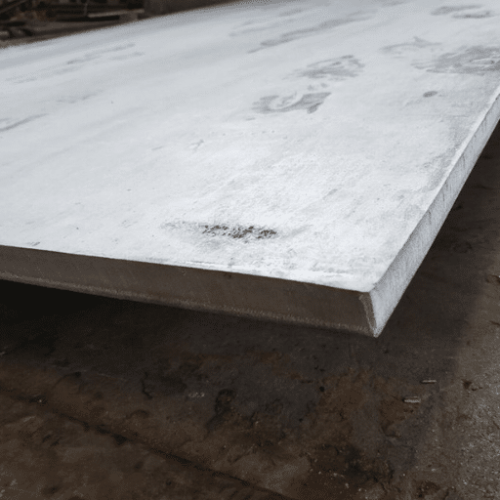

The 4j78 Iron Nickel Alloy Sheet is a high-performance material known for its excellent precision, stability, and effective resistance to temperature changes. This alloy is widely used in applications requiring minimal thermal expansion and excellent magnetic properties. Its unique blend of elements and precise manufacturing techniques make it a preferred choice in industries such as aerospace, electronics, and precision instruments.

For pricing and quotes regarding the 4j78 Iron Nickel Alloy Sheet, please contact us directly. Flexible pricing terms are available based on order size and delivery needs.

The 4j78 Iron Nickel Alloy Sheet is extensively used in the following industries and applications:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 77.5-78.5 |

| lron (Fe) | Balance |

| Carbon (C) | ≤ 0.05 |

| Silicon (Si) | ≤ 0.30 |

| Manganese (Mn) | ≤ 0.40 |

| Sulfur (S) | ≤ 0.015 |

| Phosphorus (P) | ≤ 0.020 |

| Property | Value |

|---|---|

| Tensile Strength | 520-620 MPa |

| Yield Strength | 260-300 MPa |

| Elongation | ≥30% |

| Hardness (HB) | 135-165 |

| Modulus of Elasticity | 140 GPa |

The 4j78 Iron Nickel Alloy Sheet exhibits excellent resistance to mild acids and alkalis. It performs reliably in neutral or slightly acidic environments but is not recommended for highly acidic or alkaline conditions. This alloy complies with environmental regulations, ensuring safe use in various settings.

| Environment | Resistance Level |

|---|---|

| Atmospheric (Dry) | Excellent |

| Atmospheric (Humid) | Good |

| Mild Acids (pH > 4) | Good |

| Strong Acids (pH < 4) | Poor |

| Mild Alkalis | Good |

| Saltwater | Poor |

Contact us for detailed corrosion resistance data specific to your application.

The 4j78 Iron Nickel Alloy Sheet delivered exceptional stability for our satellite components. The China manufacturer provided consistent quality and fast delivery.

Feynman K.

Aerospace Technician

This invar material is perfect for our circuit board production. Its low thermal expansion ensures precision, and the pricing terms were flexible.

Vina W.

Electronics Supplier

We rely on this nickel iron alloy for optical systems. The supplier’s expertise and reliable alloy nickel and iron composition made all the difference.

Sam B.

Research Lab Manager

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.

©2025 alloy-materials.com COPYRIGHT ALL RIGHT RESERVED.