Get in touch with us

Leave a message

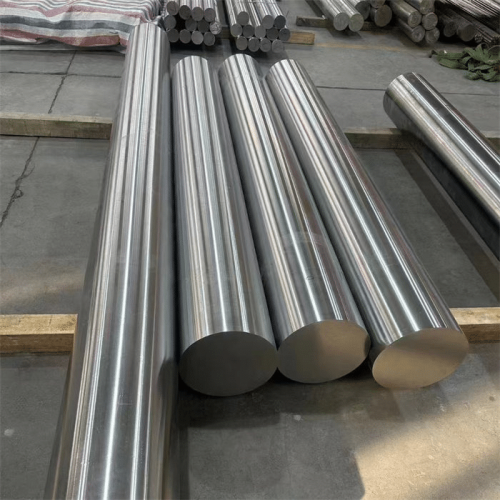

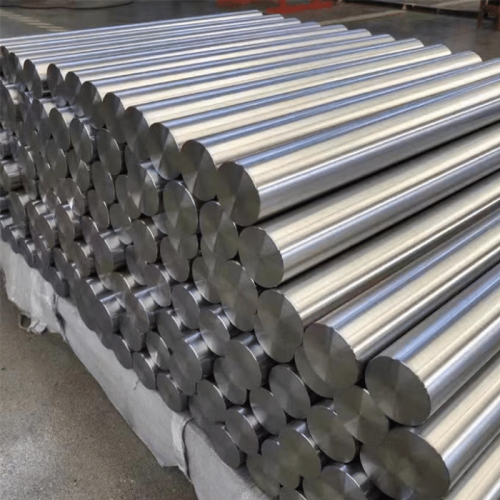

The 1J50 Iron Nickel Alloy Rod is a high-saturation magnetic induction material designed for precise industrial and engineering applications. Known for excellent thermal stability, low coercivity, and high permeability, it meets the demanding needs of aerospace, electronics, and magnetic shielding industries.

Our factory offers a variety of customizable specifications to meet your industrial needs:

Need specific dimensions, finishes, or standards? Contact our distributor to discuss your requirements!

The 1J50 Iron Nickel Alloy Bar is utilized in various industries, including:

| Element | Percentage | Purpose |

|---|---|---|

| Nickel (Ni) | 45.0-50.0% | Contributes to magnetic stability and strength. |

| Iron (Fe) | Balance | Core structural element of the alloy. |

| Manganese (Mn) | ≤ 0.30% | Enhances durability and toughness. |

| Silicon (Si) | ≤ 0.30% | Supports thermal resistance. |

| Carbon (C) | ≤ 0.05% | Improves machinability. |

| Property | Value |

|---|---|

| Tensile Strength | 500-700 MPa |

| Yield Strength | ≥ 300 MPa |

| Elongation | ≥ 30% |

| Hardness (HB) | 85-95 |

The 1J50 Iron Nickel Alloy Rod exhibits reliable chemical stability in mild environments, making it suitable for applications with low to moderate corrosive exposure. Below are its key chemical properties:

For applications involving aggressive chemical exposure, consult our technical team to explore coating options or alternative alloys.

When using the 1J50 Iron Nickel Alloy Rod, consider the following limitations to ensure optimal performance:

| Environment | Test Conditions | Corrosion Rate (mm/year) | Observations |

|---|---|---|---|

| Atmospheric (Urban) | 1-year exposure, 25°C, 65% RH | 0.002 | Negligible surface tarnish, no pitting |

| Neutral Salt Spray | 600 hours, 5% NaCl, 35°C | 0.004 | Minor discoloration, no significant pitting |

| Dilute Hydrochloric Acid | 3% HCl, 24 hours, 20°C | 0.012 | Slight surface etching, short-term use only |

| Alkaline Solution | 5% NaOH, 24 hours, 20°C | 0.002 | Excellent resistance, no degradation |

| Marine Environment | 6-month exposure, coastal, 25°C | 0.020 | Visible pitting, coating recommended |

Contact us for detailed corrosion resistance data specific to your application.

The 1J50 Iron Nickel Alloy Rod has transformed our component accuracy. Its low thermal expansion improves operational stability in avionics.

Alan W.

Aerospace Engineer

High-quality material with incomparable magnetic stability. Our electromagnetic shielding products have benefited greatly from its excellent corrosion resistance.

Mei L.

Electronics Procurement Manager

The flexibility of the 1J50 invar rod's machining properties is exceptional. It worked seamlessly in our sensor production line.

James R.

Industrial Manufacturer

A: The 1J50 Iron Nickel Alloy Rod offers high magnetic permeability, low coercivity, excellent thermal stability, and notable resistance to corrosion, making it ideal for precision electromagnetic applications.

A: It is widely used in industries such as aerospace, telecommunications, medical equipment manufacturing, and electronics for components like transformers, magnetic shielding, and precision instruments.

A: Yes, our factory provides customizable options for dimensions, surface finishes, and performance standards. Contact us to discuss your exact requirements, and we can tailor the product to meet your needs.

A: While both are soft magnetic alloys, the 1J50 contains a lower nickel content (approximately 50%) and is optimized for moderate magnetic field applications. The 1J79, with higher nickel content, is better suited for high-performance shielding and magnetic cores requiring extreme magnetic precision.

A: It resists moderate concentrations of acids and alkalis, making it durable for most industrial conditions. However, in highly corrosive or extremely moist environments, additional protective coatings may be required to maintain optimal performance.

A: Proper precautions, such as using suitable welding methods and maintaining controlled machining speeds, are necessary to preserve material properties. Its thermal resistance ensures reliable performance during welding. Contact us for guidelines on processing techniques.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.