Get in touch with us

Leave a message

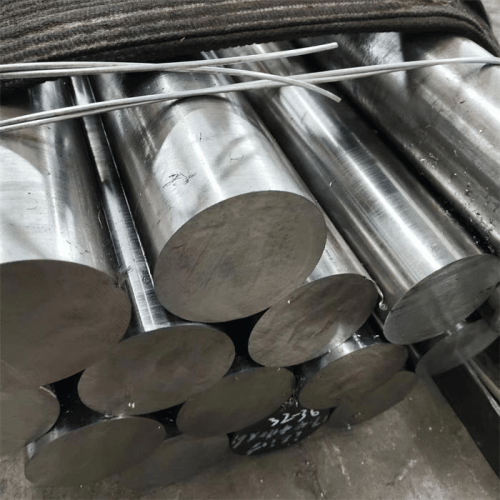

The 1J77 Iron Nickel Alloy Rod is a high-performance, precision alloy known for its exceptional magnetic properties, high mechanical strength, and corrosion resistance. Perfect for applications requiring low thermal expansion and high magnetic permeability, this rod is a must-have for industries like electronics, aerospace, and precision instruments.

The 1J77 Iron Nickel Alloy Rod is indispensable in various sectors, including but not limited to:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 77.0 - 78.0 |

| Iron (Fe) | Balance |

| Molybdenum (Mo) | 3.9 - 4.5 |

| Copper (Cu) | 4.8 - 6.0 |

| Carbon (C) | ≤ 0.03 |

| Silicon (Si) | 0.15 - 0.30 |

| Manganese (Mn) | 0.3 - 0.6 |

| Phosphorus (P), Sulfur (S) | ≤ 0.02 each |

| Property | Value |

|---|---|

| Yield Strength | 980 MPa |

| Tensile Strength | 980 MPa |

| Elongation | 2% - 40% |

| Environment | Test Conditions | Corrosion Rate (mm/year) | Observations |

|---|---|---|---|

| Atmospheric (Urban) | 1-year exposure, 25°C, 60% RH | 0.002 | Minimal surface tarnishing, no pitting |

| Neutral Salt Spray | 500 hours, 5% NaCl, 35°C | 0.005 | Slight surface discoloration, no significant pitting |

| Dilute Sulfuric Acid | 5% H₂SO₄, 24 hours, 20°C | 0.015 | Moderate surface etching, suitable for short-term exposure |

| Alkaline Solution | 5% NaOH, 24 hours, 20°C | 0.003 | Excellent resistance, no visible degradation |

| Marine Environment | 6-month exposure, coastal, 25°C | 0.025 | Noticeable pitting, protective coating recommended |

Contact us for detailed corrosion resistance data specific to your application.

By adhering to these practices, you can maximize the performance and longevity of the 1J77 Iron Nickel Alloy Rod in industrial applications.

The 1J77 Iron Nickel Alloy Rod offers unparalleled magnetic properties. It simplified our production process, yielding reliable results without delays.

Sarah T.

Precision Engineering Specialist

Amazing quality and performance! The rod’s corrosion resistance is exactly what we needed for components in high-humidity environments.

Mike R.

Electronics Industry Buyer

We used this rod for creating precision sensors. Its dimensional integrity and strength exceeded expectations. A highly recommended product!

Emma L.

Aerospace Procurement Specialist

A: The 1J77 Iron Nickel Alloy Rod is widely used in applications requiring exceptional magnetic stability. It’s commonly found in the manufacture of precision instruments, transformers, and sensors. Many customers also choose alternatives like Iron Nickel Alloy Bar for specific industrial needs.

A: The 1J77 invar rod is a highly specialized alloy designed for minimal thermal expansion, making it ideal for aerospace and metrology applications. Unlike generic bars, such as the Iron Nickel Alloy Bar, the invar rod offers unrivaled dimensional stability under temperature changes.

A: Yes, the 1J77 invar bar is highly resistant to temperature-induced expansion and mild chemical corrosion, making it suitable for challenging environments. However, like all alloys, its performance may decline in highly acidic or alkaline settings.

A: The 1J77 Iron Nickel Alloy Bar offers excellent corrosion resistance in mildly aggressive environments, such as high-humidity areas. Its chemical structure ensures durability, similar to the invar rod, while maintaining magnetic properties.

A: Yes, the 1J77 invar rod can be effectively welded using methods like Tungsten Inert Gas (TIG) welding. Preheating helps minimize thermal stress. For larger projects, it’s important to consult guidelines applicable to both the rod and an Iron Nickel Alloy Bar.

A: Industries like aerospace, precision engineering, and electronics frequently use the 1J77 Invar bar for its stability and strength. Its minimal expansion under heat makes it ideal for precision tools, much like its counterpart, the Iron Nickel Alloy Rod, in magnetic shielding applications.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.