Get in touch with us

Leave a message

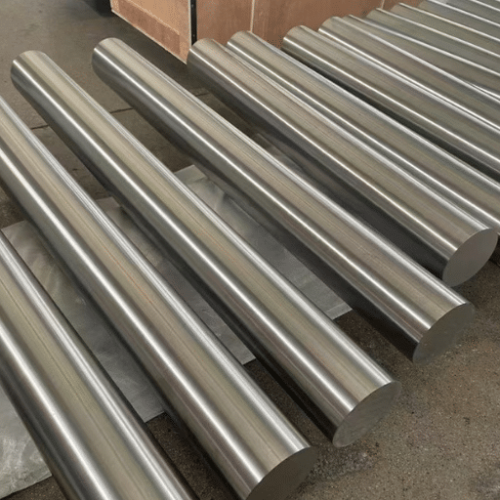

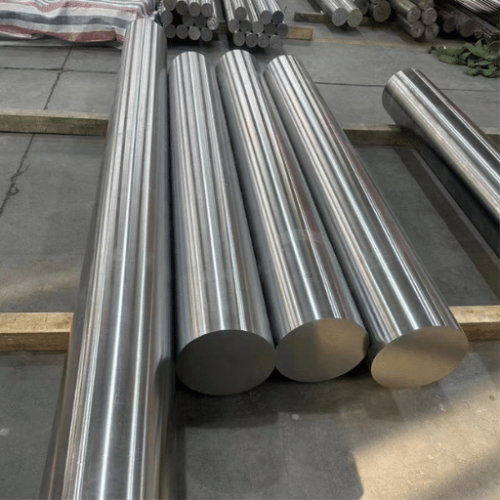

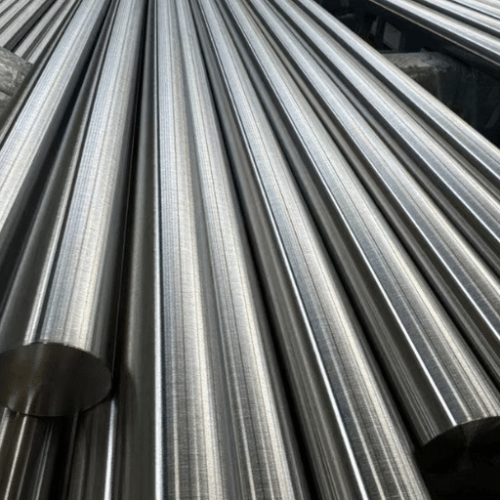

The 4j32a Iron Nickel Alloy Rod is a precision-engineered material known for its exceptional thermal and low-expansion properties. It is widely utilized in industries demanding dimensional stability, such as aerospace, electronics, and instrumentation. Manufactured with a balanced composition of iron and nickel, this alloy offers superior performance in environments requiring thermal consistency.

For pricing inquiries regarding the 4j32a Iron Nickel Alloy Rod, please contact us to request a detailed quote. Pricing terms for this product depend on specifications, order quantity, and delivery location.

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 31.5–32.5 |

| Iron (Fe) | Balance (~64) |

| Cobalt (Co) | 0.5–1.0 |

| Carbon (C) | ≤0.05 |

| Silicon (Si) | ≤0.30 |

| Manganese (Mn) | ≤0.60 |

| Property | Value |

|---|---|

| Tensile Strength | 450–550 MPa |

| Yield Strength | 200–300 MPa |

| Elongation | ≥30% |

| Hardness (HB) | 130–180 |

| Environment | Corrosion Resistance |

|---|---|

| Atmospheric (Air) | Excellent |

| Fresh Water | Excellent |

| Sea Water | Good |

| Dilute Acids | Moderate |

| Oxidizing Acids | Poor |

Contact us for detailed corrosion resistance data specific to your application.

The invar rod is ductile and weldable using:

Forming techniques include cold working and machining, with properties similar to austenitic stainless steel. Annealing may be required post-fabrication to relieve stresses.

The 4J32A Iron Nickel Alloy Rod from this China manufacturer exceeded our expectations for satellite components. Excellent dimensional stability and easy to machine.

Annie D.

Aerospace Engineer

Reliable invar bar for our resonant cavities. The low thermal expansion and corrosion resistance are perfect for our needs.

Edward T.

Electronics Supplier

Reliable nickel iron alloy for precision instruments. Great corrosion resistance and easy to work with.

Emma S.

Precision Instrument Maker

A: Its unique low thermal expansion and high strength properties make it ideal for precision applications.

A: Yes, the diameter, length, and surface finish can be tailored to meet customer needs.

A: Aerospace, electronics, instrumentation, and optics.

A: It offers excellent resistance to atmospheric and mild chemical corrosion but requires precautions for harsh environments.

A: TIG and MIG welding methods are ideal. Pre-heating and post-weld treatments are advised for optimal results.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.