Get in touch with us

Leave a message

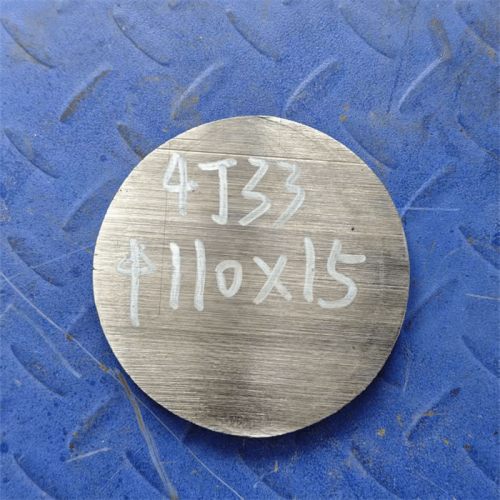

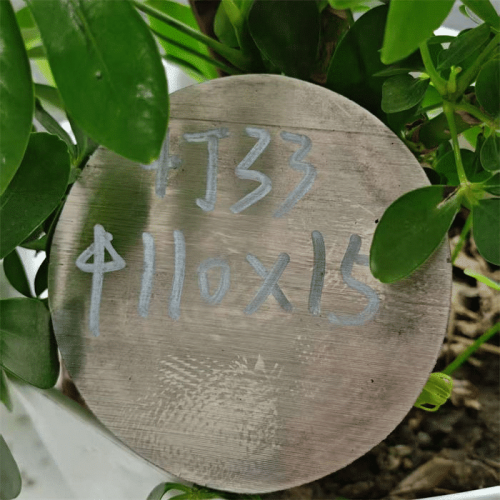

Our 4J33 Nickel Iron Alloy Rod comes in various forms:

Need specific Iron Nickel Alloy Bar specs? Our China factory offers tailored solutions!

The 4J33 Alloy Rod serves precision-driven industries:

From aerospace to optics, its uses are specialized and critical.

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 32.0–33.5 |

| Iron (Fe) | Balance |

| Manganese (Mn) | ≤ 0.5 |

| Silicon (Si) | ≤ 0.2 |

| Carbon (C) | ≤ 0.05 |

| Phosphorus (P) | ≤ 0.02 |

| Sulfur (S) | ≤ 0.02 |

| Cobalt (Co) | ≤ 0.5 |

| Property | Value |

|---|---|

| Tensile Strength | 450–600 MPa |

| Yield Strength (0.2%) | ≥ 280 MPa |

| Elongation | ≥ 30% |

| Hardness (Brinell) | 130–160 HB |

| Density | 8.1 g/cm³ |

The 4J33 Alloy Bar resists:

The 4J33 Nickel Iron Alloy has constraints:

Our China distributor can recommend alternatives if needed.

| Environment | Corrosion Resistance | Notes |

|---|---|---|

| Atmospheric (Dry) | Good | Resists rust in dry, non-humid conditions. |

| Atmospheric (Humid) | Moderate | Susceptible to rust with prolonged moisture. |

| Saltwater (Marine) | Fair | Prone to pitting and corrosion in saline environments. |

| Mild Acids (e.g., Acetic) | Moderate | Handles dilute acids; poor with strong acids. |

| Alkaline Solutions | Good | Resists bases like sodium hydroxide in mild conditions. |

Contact us for detailed corrosion resistance data specific to your application.

Welding 4J33 Iron Nickel Alloy Round Bar requires care:

Tips:

Our China factory offers pre-machined 4J33 Alloy Bar options.

Emma R.

Optical Engineer

John T.

Electronics Specialist

Lisa M.

Aerospace Technician

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.