Get in touch with us

Leave a message

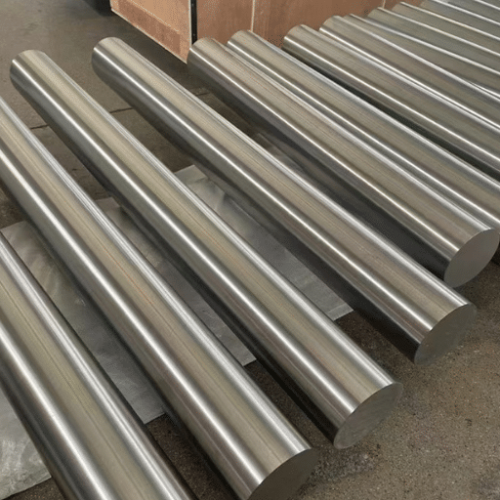

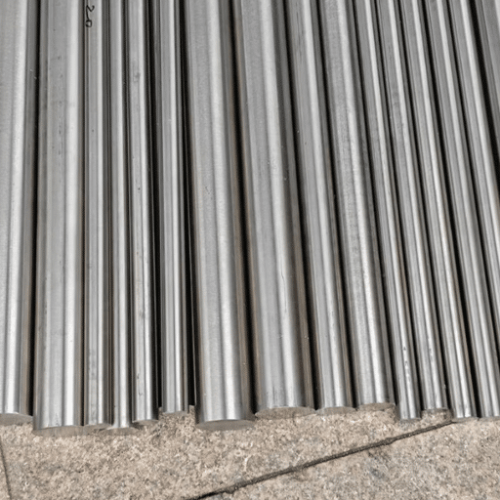

The 4j36 Iron Nickel Alloy Bar, also known as Invar 36 or FeNi36, is a low-expansion nickel-iron alloy renowned for its minimal thermal expansion across a wide temperature range. This invar bar, composed primarily of 36% nickel and 64% iron, is ideal for precision engineering applications requiring dimensional stability, such as aerospace, electronics, and scientific instruments. Its unique properties make it a top choice for industries needing reliable performance under varying thermal conditions.

The 4j36 Iron Nickel Alloy Bar is widely used in the following industries and applications:

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 35.0 - 37.0 |

| Iron (Fe) | Balance (Remaining) |

| Carbon (C) | ≤ 0.05 |

| Manganese (Mn) | ≤ 0.60 |

| Silicon (Si) | ≤ 0.30 |

| Sulfur (S) | ≤ 0.02 |

| Phosphorus (P) | ≤ 0.02 |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 490 MPa |

| Yield Strength | ≥ 240 MPa |

| Elongation | ≥ 35% |

| Hardness (Brinell) | 130 - 160 HB |

| Density | 8.13 g/cm³ |

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Neutral Atmosphere | Negligible |

| Mild Sea Water | < 0.05 |

| Weak Acid (pH 5) | 0.01 – 0.02 |

| Strong Acid (pH 2) | Not Recommended |

Contact us for detailed corrosion resistance data specific to your application.

4j36 Iron Nickel Alloy Bar can be easily welded using TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding methods. Standard precautions should be followed for thermal expansion control during welding. Additionally, the alloy offers exceptional performance during forming, milling, and machining processes.

The 4j36 Iron Nickel Alloy Bar we purchased from this manufacturer exceeded our expectations. Its precision and stability are unparalleled.

Jane R.

Aerospace Engineer

We highly recommend their 4j36 alloy bars for any application dealing with thermal expansion challenges. Their customer service was also exceptional.

Robert T.

Electronics Industry Professional

Reliable performance and terrific machinability. This supplier is our go-to for 4j36 alloy products. Highly satisfied!

Mei Wong

Industrial Buyer

A: It offers a low coefficient of thermal expansion, making it ideal for precision applications in varying temperatures.

A: 4j36 features a superior thermal expansion control and remains stable over a wide range of temperatures.

A: Aerospace, electronics, scientific instrumentation, and cryogenic systems widely use this material.

A: Yes, it is resistant to mild acids and alkalines but should be avoided in strong oxidizing acids.

A: Absolutely, we offer a variety of dimensions to meet your project requirements.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.