Get in touch with us

Leave a message

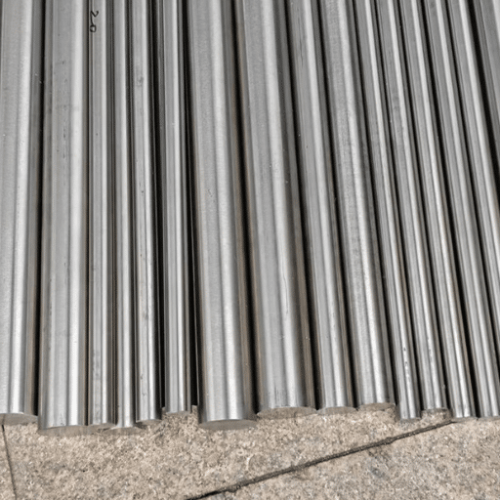

The 4j47 Iron Nickel Alloy Bar is a precision-engineered material widely used in industrial applications due to its exceptional thermal and mechanical properties. This nickel-iron alloy is known for its excellent dimensional stability, low expansion coefficient, and high resistance to various environmental conditions. These characteristics make it an ideal choice for components in scientific instruments, aerospace systems, and electronic devices.

For pricing inquiries and customized orders, please contact our sales team. Terms for the 4j44 Iron Nickel Alloy Bar include competitive rates and tailored solutions to meet your industrial needs.

The 4j44 Iron Nickel Alloy Bar is widely used in:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 43.5-44.5 |

| lron (Fe) | Balance |

| Carbon (C) | ≤0.05 |

| Manganese (Mn) | ≤0.50 |

| Silicon (Si) | ≤0.30 |

| Sulfur (S) | ≤0.02 |

| Phosphorus (P) | ≤0.02 |

| Property | Value |

|---|---|

| Tensile Strength | 550-700 MPa |

| Yield Strength | 300-450 MPa |

| Elongation | ≥20% |

| Hardness (Brinell) | 140-180 HB |

| Density | 8.1 g/cm³ |

| lron Nickel Alloy Melting Point | ~1450°C |

| Environment | Corrosion Rate (mm/year) | Notes |

|---|---|---|

| Atmospheric (Urban) | <0.01 | Excellent resistance |

| Seawater | 0.05-0.1 | Moderate; coatings advised |

| Dilute Sulfuric Acid | 0.1-0.5 | Limited resistance; use cautiously |

| Sodium Hydroxide (10%) | <0.01 | High resistance |

Contact us for detailed corrosion resistance data specific to your application.

Recommended Welding Methods:

Forming Techniques: Cold forming recommended; avoid excessive bending to prevent cracking.

Processing: Machinable with standard tools; annealing may be required post-forming to restore properties.

The 4j44 Iron Nickel Alloy Bar from this China manufacturer exceeded expectations. Its low thermal expansion is perfect for our satellite components. Highly reliable!

Jason W.

Aerospace Engineer

We’ve used this invar bar for magnetic shielding. Consistent quality and excellent support from the factory make it our go-to choice.

Charlie B.

Electronics Supplier

The nickel iron alloy properties are spot-on for our precision devices. Fast delivery and customizable options are a big plus.

Lucy K.

Instrument Manufacturer

A: Its controlled thermal expansion makes it ideal for precision applications.

A: Yes, we offer fully customizable sizing options.

A: Approximately 1,450°C (2,642°F).

A: Absolutely, its low outgassing properties make it perfect for vacuum applications.

A: It performs well in neutral and mildly acidic conditions but should be avoided in strongly oxidative environments.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.