Get in touch with us

Leave a message

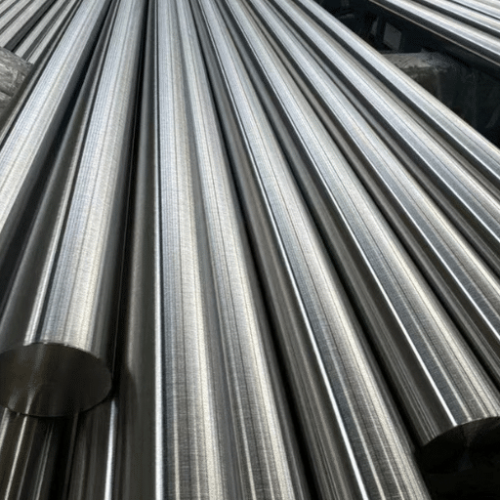

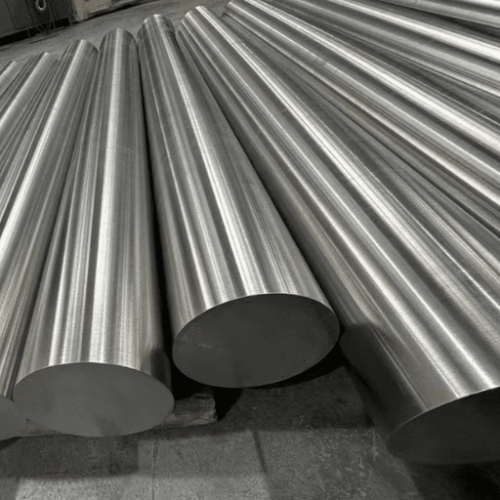

The 4j47 Iron Nickel Alloy Bar is a precision-engineered material widely used in industrial applications due to its exceptional thermal and mechanical properties. This nickel-iron alloy is known for its excellent dimensional stability, low expansion coefficient, and high resistance to various environmental conditions. These characteristics make it an ideal choice for components in scientific instruments, aerospace systems, and electronic devices.

Contact our sales team for a customized quote on 4J47 Iron Nickel Alloy Bar. Pricing depends on specifications and order volume.

The 4J47 Iron Nickel Alloy Bar is tailored for industries needing precision and stability:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 46.0–48.0 |

| Iron (Fe) | Balance (~51) |

| Carbon (C) | ≤0.05 |

| Silicon (Si) | ≤0.30 |

| Manganese (Mn) | ≤0.50 |

| Phosphorus (P) | ≤0.02 |

| Sulfur (S) | ≤0.02 |

| Property | Value |

|---|---|

| Tensile Strength | 450–550 MPa |

| Yield Strength | 200–300 MPa |

| Elongation | ≥25% |

| Hardness (HB) | 120–160 |

| Environment | Corrosion Resistance |

|---|---|

| Atmospheric (Air) | Excellent |

| Fresh Water | Good |

| Sea Water | Moderate |

| Dilute Acids | Moderate |

| Oxidizing Acids | Poor |

Contact us for detailed corrosion resistance data specific to your application.

The invar rod supports various welding methods:

It can be machined and cold-worked similarly to stainless steel. Preheating and post-weld annealing at 540–650°C enhance weld integrity.

The 4J47 Iron Nickel Alloy Bar from this China factory is perfect for our lead frames. Stable and easy to fabricate.

Alan R.

Electronics Manufacturer

This invar bar delivers unmatched dimensional stability for our sensors. High-quality product from a reliable supplier.

Mei H.

Aerospace Engineer

The nickel iron alloy’s low expansion and corrosion resistance are ideal for our fiber optic components.

Tom S.

Telecom Supplier

A: The alloy’s controlled thermal expansion properties and precise composition make it uniquely suited for critical applications.

A: Industries such as aerospace, electronics, and precision instruments widely utilize the 4j47 alloy.

A: It is moderately resistant to corrosion but not suitable for prolonged exposure to marine environments.

A: Custom sizes can be manufactured to meet specific requirements.

A: Yes, it supports standard industrial welding techniques.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.