Get in touch with us

Leave a message

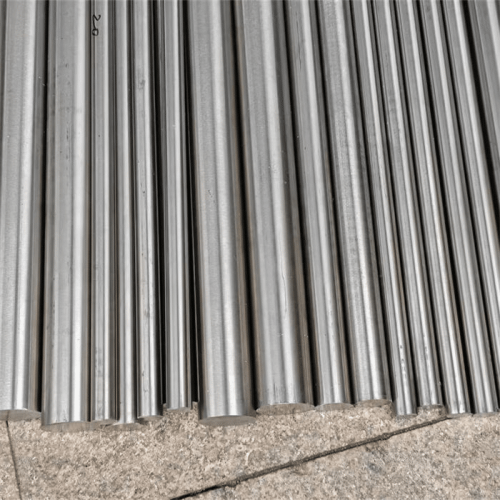

The Invar 36 Rod, also known as Iron Nickel Alloy Bar, is a low-expansion nickel-iron alloy with a unique coefficient of thermal expansion (CTE) close to zero. Comprising 36% nickel, this alloy is ideal for applications requiring dimensional stability across a wide temperature range. As a leading Invar 36 Rod manufacturer in China, we supply high-quality rods for industries demanding precision and reliability.

For the most competitive pricing, reach out to our sales team directly. We offer customized quotes for Invar 36 rod price based on your specific requirements, including dimensions, quantity, and delivery timelines. Contact us today to discuss your needs!

Our Invar Rod is available in various dimensions and finishes to meet diverse industrial requirements. Below are the typical specifications:

Invar 36 Bar is widely used in industries where precision and stability are critical. Common applications include:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 35.0–37.0 |

| Iron (Fe) | Balance |

| Manganese (Mn) | 0.2–0.6 |

| Silicon (Si) | 0.4 max |

| Carbon (C) | 0.05 max |

| Sulfur (S) | 0.015 max |

| Phosphorus (P) | 0.015 max |

| Property | Value |

|---|---|

| Tensile Strength | 490 MPa |

| Yield Strength (0.2% offset) | 280 MPa |

| Elongation | 30% |

| Hardness (Brinell) | 140 HB |

| Density | 8.05 g/cm³ |

Invar 36 exhibits moderate resistance to various corrosive environments:

| Environment | Corrosion Rate (mm/year) | Conditions | Notes |

|---|---|---|---|

| Dry Atmosphere | <0.002 | 25°C, 12 months exposure | No significant corrosion |

| Humid Atmosphere (Coastal) | 0.01 | 25°C, 12 months exposure | Slight surface rust; coating advised |

| Distilled Water | 0.005 | 25°C, 6 months exposure | Minimal corrosion |

| 5% Sulfuric Acid | 0.15 | 30°C, 1 month exposure | Not recommended for prolonged exposure |

| 5% Sodium Chloride (Saltwater) | 0.08 | 25°C, 3 months exposure | Use protective coatings for marine use |

| 5% Sodium Hydroxide (Alkaline) | 0.015 | 40°C, 3 months exposure | Good resistance |

We’ve been using Invar 36 Rod from this manufacturer for our high-precision optical equipment, and the results are exceptional. The low thermal expansion ensures our components stay stable across temperature changes. Their team also helped us customize the Invar 36 round bar to exact specifications, and the quality has been consistently excellent. A reliable partner for our business!

Michael P.

Precision Instrument Designer

The Invar 36 round bar we ordered performed perfectly in our scientific instruments. Delivery was prompt, and the pricing was competitive. A reliable supplier!

Emily S.

Procurement Specialist

We’ve been sourcing Invar 36 Bar from this China-based manufacturer for our precision aerospace components, and the quality is top-notch. The low-expansion properties are exactly as specified, and their team was incredibly helpful in meeting our tight tolerances.

David R.

Aerospace Engineer

A: Invar 36 Rods has a significantly lower coefficient of thermal expansion compared to stainless steel, making it ideal for precision applications where dimensional stability is critical. Stainless steel, however, offers better corrosion resistance in harsh environments.

A: Invar 36 Round Bar maintains its low-expansion properties up to 400°C. Beyond this temperature, its CTE increases, so it’s not recommended for high-temperature applications without consulting our technical team.

A: Invar 36 Bar is commonly used in aerospace, electronics, scientific instrumentation, and telecommunications for applications requiring minimal thermal expansion and high precision.

A: Yes, Invar 36 retains its low-expansion properties and mechanical strength at cryogenic temperatures, making it ideal for applications like liquid nitrogen storage systems.

A: We offer Invar 36 round bar in cold drawn, hot rolled, polished, or custom finishes. Contact us to discuss the best finish for your application.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.