Get in touch with us

Leave a message

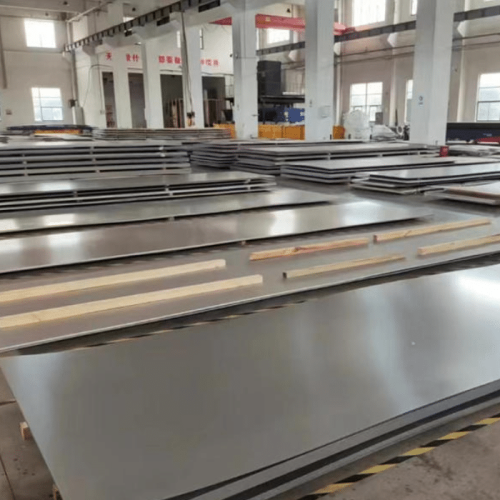

18Ni300 Maraging Steel Plate is an ultra-high-strength, low-carbon alloy designed for top-tier toughness and precision. With 18% nickel and a unique aging process, this Hot Rolled or Cold Rolled plate excels in aerospace, tooling, and defense applications, offering strength without sacrificing ductility.

Need pricing for 18Ni300 Maraging Steel Plate? Contact us at sales for a tailored quote. Our Cold-Rolled and Hot-Rolled options deliver exceptional value for high-performance needs.

Our Steel Plate comes in various configurations:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 17.0 - 19.0 |

| Cobalt (Co) | 8.0 - 12.0 |

| Molybdenum (Mo) | 3.0 - 5.0 |

| Titanium (Ti) | 0.6 - 1.2 |

| Iron (Fe) | Balance |

| Carbon (C) | ≤ 0.03 |

| Silicon (Si) | ≤ 0.1 |

| Property | Value (Aged) |

|---|---|

| Tensile Strength | 1900 - 2060 MPa |

| Yield Strength | 1860 - 2000 MPa |

| Elongation | ≥ 6% |

| Hardness (HB) | 550 - 600 |

| Environment | Corrosion Rate (mm/year) | Test Conditions | Factors Affecting Corrosion |

|---|---|---|---|

| Atmospheric (Air) | 0.02 – 0.05 | Ambient humidity, 20-25°C | Surface finish, exposure time |

| Seawater (3.5% NaCl) | 0.1 – 0.2 | 25°C, aerated, as-built condition | Build orientation, heat treatment |

| Sulfuric Acid (10%) | 0.3 – 0.5 | 25°C, de-aerated, aged condition | Pore size, heat treatment |

| Hydrochloric Acid (1M) | 0.5 – 0.8 | 25°C, with 1 mM H₂S, CO₂ saturated | Austenite reversion, aging temperature |

| Nitric Acid (10%) | 0.8 – 1.2 | 25°C, oxidizing environment | Lack of Cr, heat treatment |

Welding 18Ni300 Maraging Steel Sheet is efficient:

Alex P.

Aerospace Engineer

Liam T.

Defense Contractor

Rita S.

Tooling Specialist

A: Very weldable with TIG and matching fillers—age post-weld at 480°C to restore the Cold Drawn 18Ni300 Maraging Steel Sheet’s full strength.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.