Get in touch with us

Leave a message

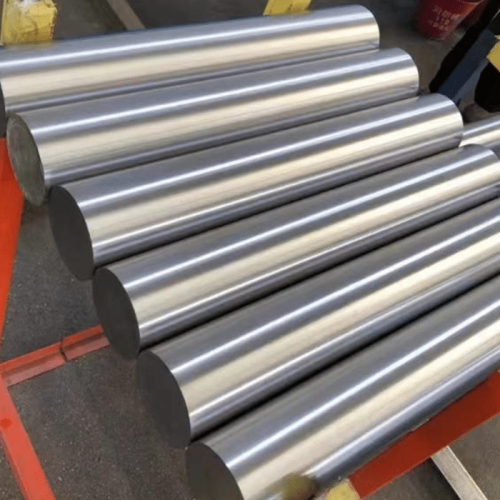

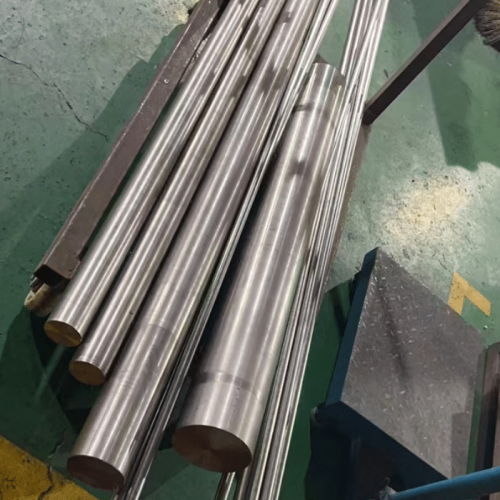

18Ni300 Maraging Steel Rod is a low-carbon, ultra-high-strength alloy engineered for exceptional toughness and precision. With 18% nickel and a unique aging process, this Round bar excels in aerospace, defense, and tooling, delivering strength up to 2060 MPa after heat treatment—perfect for critical applications.

Interested in 18Ni300 Maraging Steel Rod pricing? Contact us at sales for a custom quote. Our Round bar and hexagonal bar options offer top performance at competitive rates.

Our Steel Rod comes in various configurations:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 17.0 - 19.0 |

| Cobalt (Co) | 8.0 - 12.0 |

| Molybdenum (Mo) | 3.0 - 5.0 |

| Titanium (Ti) | 0.6 - 1.2 |

| Iron (Fe) | Balance |

| Carbon (C) | ≤ 0.03 |

| Silicon (Si) | ≤ 0.1 |

| Property | Value (Aged) |

|---|---|

| Tensile Strength | 1900 - 2060 MPa |

| Yield Strength | 1860 - 2000 MPa |

| Elongation | ≥ 6% |

| Hardness (HB) | 550 - 600 |

18Ni300 Steel offers moderate resistance to mild acids and alkalis but falters in highly oxidizing conditions like nitric acid due to low chromium content. Its strength-focused design prioritizes toughness over corrosion resistance.

| Environment | Corrosion Rate (mm/year) | Test Conditions | Factors Affecting Corrosion |

|---|---|---|---|

| Atmospheric (Air) | 0.02 – 0.05 | Ambient, 20-25°C, 50% humidity | Humidity, surface finish |

| Seawater (3.5% NaCl) | 0.1 – 0.2 | 25°C, aerated, as-built condition | Build orientation, aging |

| Sulfuric Acid (10%) | 0.3 – 0.5 | 25°C, de-aerated, aged condition | Pore size, heat treatment |

| Hydrochloric Acid (1M) | 0.5 – 0.8 | 25°C, 1 mM H₂S, CO₂ saturated | Austenite reversion, aging temp |

| Nitric Acid (10%) | 0.8 – 1.2 | 25°C, oxidizing environment | Low Cr content, heat treatment |

| Caustic Soda (10%) | 0.05 – 0.1 | 25°C, de-aerated | Temperature, concentration |

Mark D.

Aerospace Technician

Liam T.

Defense Contractor

Nina K.

Tooling Engineer

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.