Get in touch with us

Leave a message

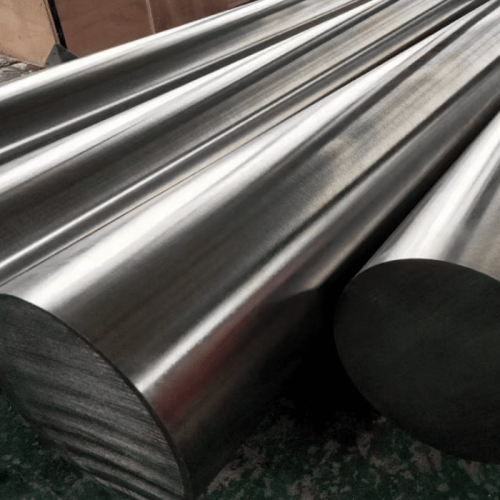

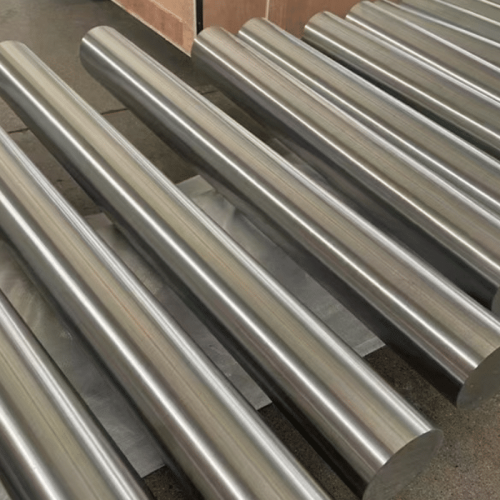

Need pricing for 18Ni350 Maraging Steel Rod? Contact us at sales for a custom quote. Our Round bar and hexagonal bar options offer premium value for high-performance applications.

Our 18Ni350 Maraging Steel Bar comes in various configurations:

The 18Ni350 Maraging Steel Bar serves a wide range of industries:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 17.0 - 19.0 |

| Cobalt (Co) | 11.5 - 12.5 |

| Molybdenum (Mo) | 4.6 - 5.2 |

| Titanium (Ti) | 1.3 - 1.6 |

| Aluminum (Al) | 0.05 - 0.15 |

| Iron (Fe) | Balance |

| Carbon (C) | ≤ 0.03 |

| Property | Value (Aged) |

|---|---|

| Ultimate Tensile Strength | 2400 - 2500 MPa |

| Yield Strength | 2300 - 2400 MPa |

| Elongation | 6 - 8% |

| Hardness (Rockwell C) | 50 - 54 HRC |

| Environment | Exposure Condition | Corrosion Rate (mm/year) | Resistance Level |

|---|---|---|---|

| Atmospheric (Dry, Urban) | 20°C, 50% RH, 1-year exposure | 0.005 – 0.010 | High |

| Atmospheric (Humid, Coastal) | 25°C, 85% RH, 1-year exposure | 0.015 – 0.030 | Moderate |

| Distilled Water | 25°C, immersion, 30 days | 0.002 – 0.005 | High |

| Seawater (3.5% NaCl Solution) | 25°C, immersion, 30 days | 0.050 – 0.100 | Low |

| Dilute Sulfuric Acid (5% H2SO4) | 25°C, immersion, 7 days | 0.200 – 0.300 | Low |

| Dilute Sodium Hydroxide (5% NaOH) | 25°C, immersion, 7 days | 0.010 – 0.020 | Moderate to High |

| Salt Spray (ASTM B117) | 35°C, 5% NaCl, 96-hour exposure | 0.030 – 0.050 | Moderate |

| High-Temperature Oxidation | 400°C, air exposure, 100 hours | 0.001 – 0.003 | High |

Welding 18Ni350 Maraging Steel Bar is efficient:

John D.

Aerospace Engineer

Alex T.

Automotive Parts Manufacturer

Sarah L.

Defense Contractor

A:While the 18Ni350 Maraging Steel Rod offers moderate corrosion resistance, it’s not ideal for prolonged exposure to marine environments without protective coatings. In humid or salty conditions, surface treatments like cadmium plating or phosphating are recommended to prevent pitting corrosion, especially for components in round bar or hexagonal bar shapes.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.