Get in touch with us

Leave a message

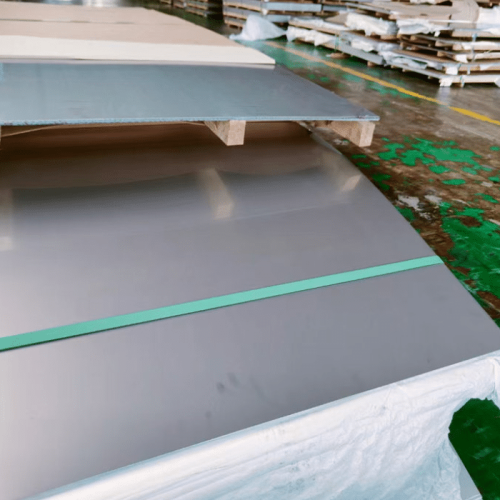

The Monel 505 Plate is a high-performance nickel-copper alloy renowned for its exceptional corrosion resistance and strength in extreme environments. Engineered for demanding industrial applications, this monel material offers durability and versatility, making it a top choice for industries like marine, chemical processing, and aerospace. Its unique monel composition ensures reliability in harsh conditions.

For competitive pricing on Monel 505 Plate, please contact our sales team. We offer flexible pricing terms tailored to your project needs, including bulk order discounts for monel material. Reach out today to discuss your requirements and receive a personalized quote.

The Monel 505 Plate is widely used across industries due to its robust monel material specification. Common applications include:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 63.0 min |

| Copper (Cu) | 28.0 - 34.0 |

| Iron (Fe) | 2.5 max |

| Manganese (Mn) | 2.0 max |

| Carbon (C) | 0.3 max |

| Silicon (Si) | 0.5 max |

| Sulfur (S) | 0.024 max |

| Property | Value |

|---|---|

| Tensile Strength | 550 - 760 MPa |

| Yield Strength (0.2% Offset) | 240 - 450 MPa |

| Elongation | 20 - 40% |

| Hardness (Brinell) | 140 - 240 |

The Monel 505 Plate exhibits excellent resistance to corrosive environments, including:

Environmental Restrictions: Avoid prolonged exposure to high concentrations of oxidizing acids like nitric acid, which may cause degradation.

While highly versatile, the Monel 505 Plate has some limitations:

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Rural) | <0.01 |

| Seawater (Static) | <0.02 |

| 10% Sulfuric Acid | 0.1 – 0.3 |

| 5% Hydrochloric Acid | 0.05 – 0.2 |

The Monel 505 Plate is easily fabricated using standard techniques. Recommended methods include:

Tip: Pre-clean surfaces to avoid contamination during welding, ensuring optimal joint strength.

We sourced Monel 505 Plate for our seawater valves, and the corrosion resistance is outstanding. The plates were delivered on time and met all specifications.

John D.

Marine Engineer

The monel 505 plate we purchased was easy to fabricate and has performed flawlessly in our acidic environment. Highly recommend this supplier!

Sarah K.

Chemical Plant Manager

These plates are perfect for our high-stress components. The monel 505 plate quality is top-notch, and the pricing was competitive.

Michael T.

Aerospace Technician

A: While both are nickel-copper alloys, Monel K500 includes aluminum and titanium for enhanced strength and hardness through age-hardening, whereas Monel 505 Plate prioritizes corrosion resistance and workability.

A: It is commonly used in marine, chemical, aerospace, oil and gas, and power generation industries.

A: It is recyclable and durable, reducing replacement frequency, but avoid use in highly oxidizing environments to maintain performance.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.