Get in touch with us

Leave a message

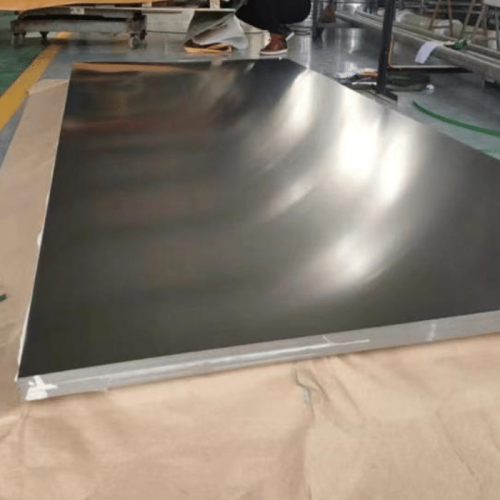

Monel K500 Plate is a nickel-copper alloy enhanced with aluminum and titanium, delivering exceptional strength and corrosion resistance. Known for its age-hardening process, this alloy outperforms Monel 400 with triple the yield strength, making it a top choice for marine, chemical, and oil/gas applications where durability is non-negotiable.

Are you curious about Monel K500 Plate pricing? Contact us at sales for a personalized quote. Our Monel K500 sheet and plate options offer competitive rates with superior performance.

Our Monel Plate comes in various configurations:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 63.0 - 70.0 |

| Copper (Cu) | 27.0 - 33.0 |

| Aluminum (Al) | 2.3 - 3.15 |

| Titanium (Ti) | 0.35 - 0.85 |

| Iron (Fe) | ≤ 2.0 |

| Manganese (Mn) | ≤ 1.5 |

| Carbon (C) | ≤ 0.25 |

| Silicon (Si) | ≤ 0.5 |

| Property | Value (Aged) |

|---|---|

| Tensile Strength | 965 - 1100 MPa |

| Yield Strength | 690 - 760 MPa |

| Elongation | ≥ 20% |

| Hardness (HB) | 280 - 350 |

Monel K500 Sheet excels in resisting hydrochloric and hydrofluoric acids in de-aerated conditions and performs well against alkalis. However, it’s less effective in oxidizing environments like nitric acid, where corrosion rates increase due to its nickel-copper base.

| Environment | Corrosion Rate (mm/year) | Test Conditions | Factors Affecting Corrosion |

|---|---|---|---|

| Atmospheric (Air) | 0.002 – 0.01 | Ambient, 20-25°C, 50% humidity | Humidity, sulfur presence |

| Seawater (Flowing) | < 0.05 | 25°C, aerated, high velocity | Velocity, biofouling |

| Seawater (Stagnant) | 0.1 – 0.3 | 25°C, stagnant, under deposits | Stagnation, crevice conditions |

| Sulfuric Acid (10%) | 0.1 – 0.2 | 25°C, de-aerated | Aeration, temperature |

| Hydrochloric Acid (10%) | 0.1 – 0.25 | 25°C, de-aerated | Concentration, aeration |

| Hydrofluoric Acid (50%) | 0.05 – 0.15 | 25°C, unaerated, up to boiling | Aeration, temperature |

| Nitric Acid (10%) | 0.5 – 1.0 | 25°C, oxidizing environment | Concentration, oxidizing agents |

| Caustic Soda (50%) | 0.02 – 0.05 | 100°C, de-aerated | Temperature, concentration |

Welding Monel K500 Sheet is efficient:

Lisa H.

Chemical Technician

Mike B.

Marine Engineer

Sam K.

Oil & Gas Supervisor

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.