Get in touch with us

Leave a message

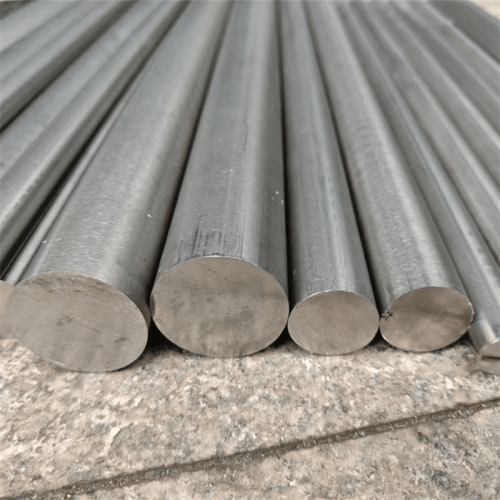

The Monel 405 Rod, also known as Monel 405 Round Bar, is a nickel-copper alloy engineered for superior corrosion resistance and machinability. Produced by a leading Chinese manufacturer, this alloy is ideal for marine, chemical, and industrial applications where durability and resistance to harsh environments are critical.

Our Monel 405 Rods are manufactured with precision to meet strict industry standards.

The Monel 405 Rod is widely used in industries such as:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 63.0 min |

| Copper (Cu) | 28.0–34.0 |

| Iron (Fe) | 2.5 max |

| Sulfur (S) | 0.025–0.060 |

| Manganese (Mn) | 2.0 max |

| Carbon (C) | 0.3 max |

| Silicon (Si) | 0.5 max |

| Property | Value |

|---|---|

| Tensile Strength | 480 - 620 MPa |

| Yield Strength | 170 - 275 MPa |

| Elongation | 35 - 50% |

| Hardness (HB) | 110 - 150 |

The Monel 405 Rod offers robust resistance to various chemicals:

| Environment | Test Conditions | Corrosion Rate (mm/year) | Observations |

|---|---|---|---|

| Seawater | 1-year exposure, 25°C | 0.001 | Minimal pitting, excellent performance |

| Sulfuric Acid | 10% H₂SO₄, 500 hours, 20°C | 0.005 | Slight surface etching, suitable for short-term use |

| Sodium Hydroxide | 5% NaOH, 24 hours, 20°C | 0.002 | No visible degradation, high resistance |

| Nitric Acid | 5% HNO₃, 24 hours, 20°C | 0.050 | Significant corrosion, not recommended |

| Atmospheric (Coastal) | 1-year exposure, 25°C, 70% RH | 0.003 | Negligible tarnishing, no pitting |

Contact us for detailed corrosion resistance data specific to your application.

These attributes make Monel 405 a reliable choice for high-production machining environments and critical industrial components.

The Monel 405 Rods delivered exceptional machinability on our automatic lathes. High precision and consistency across the batch made production seamless. We're impressed by the reliable quality and timely delivery.

James P.

Engineer

These rods are perfect for high-corrosion environments. The dimensional accuracy and surface finish exceeded expectations. Customer service was professional, with quick responses to all customization requests.

Sophia L.

Procurement Manager

Outstanding durability and performance in seawater applications. We've seen improved efficiency in pump components. Trustworthy supplier with great technical knowledge and industry expertise.

Ahmed K.

Marine Equipment Manufacturer

A: Monel 405 has added sulfur, improving machinability while maintaining strength and corrosion resistance similar to Monel 400.

A: We provide diameter adjustments, length variations, and surface finishes tailored to your requirements.

A: Key industries include marine, chemical processing, oil and gas, and nuclear energy.

A: Monel 405 remains stable up to 480°C, performing reliably under high-temperature conditions in controlled environments.

A: Yes, Monel 405 provides excellent resistance to corrosive chemicals like de-aerated acids, though additional coatings might be needed in extreme conditions.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.