Get in touch with us

Leave a message

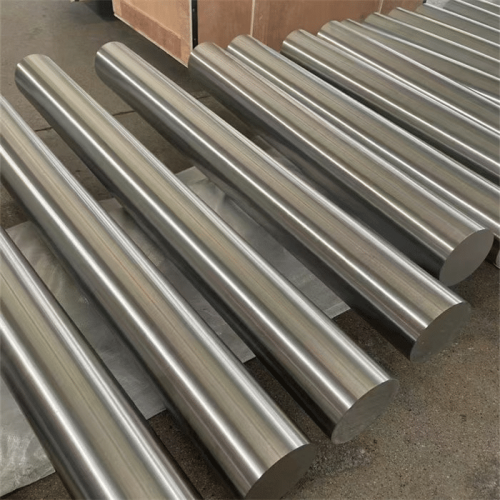

Monel 505 Round Bar, a high-strength nickel-copper alloy with excellent corrosion resistance and mechanical properties, is ideal for applications in challenging environments, such as marine engineering, chemical processing, and nuclear power plants. It is derived from Monel K-500 through the addition of aluminum and titanium, enhancing its robustness and durability.

Our China factory provides a range of customizable specs for Monel 505 Round Bar to meet your project requirements:

Monel 505 Round Bar is engineered for demanding industries, including but not limited to:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 63.0–67.0 |

| Copper (Cu) | 28.0–33.0 |

| Aluminum (Al) | 2.3–3.15 |

| Titanium (Ti) | 0.35–0.85 |

| Iron (Fe) | ≤2.0 |

| Manganese (Mn) | ≤1.0 |

| Sulfur (S) | ≤0.01 |

| Carbon (C) | ≤0.10 |

| Silicon (Si) | ≤0.5 |

| Property | Value |

|---|---|

| Tensile Strength | 490 - 630 MPa |

| Yield Strength | 175 - 290 MPa |

| Elongation | 32 - 48% |

| Hardness (HB) | 110 - 150 |

The Monel 505 Round Bar demonstrates outstanding chemical resistance capabilities:

| Environment | Chemical Composition | Temperature (°C) | Corrosion Rate (mm/year) | Resistance Level |

|---|---|---|---|---|

| Seawater | NaCl ~3.5% | 25 | <0.01 | Excellent |

| Hydrofluoric Acid | HF 10% | 20 | 0.05 ± 0.01 | High |

| Sulfuric Acid | H2SO4 85% | 50 | 0.2 ± 0.03 | Moderate |

| High-Temperature Air | Oxygen-rich atmosphere | 600 | <0.02 | Excellent |

| Chloride Solutions | NaCl 10% | 30 | <0.005 | Highly Resistant |

| Brine (High Flow) | NaCl ~5% | 25 | 0.03 | Good, with reduced performance |

| Industrial Wastewater | Mixed acids and alkalis | 40 | 0.07 ± 0.02 | Moderate to High |

| Hydrochloric Acid | HCl 5% | 25 | 0.1 ± 0.03 | Moderate |

Contact us for detailed corrosion resistance data specific to your application.

These practices ensure efficient handling and reliable performance in industrial applications.

We’ve relied on Monel 505 Round Bars for our pipeline tools. Their performance in high-pressure, corrosive environments has been unparalleled, making them our top pick!

Daniel W.

Oilfield Engineer

Outstanding corrosion resistance and high durability make this material ideal for marine pump shafts. Delivery was timely, and support was excellent.

Emily R.

Marine Contractor

Exceptional strength and accuracy! The bars we ordered have significantly improved the efficiency and safety of our chemical processing equipment.

Victor T.

Chemical Plant Manager

A: Monel 505 builds on Monel K-500, with optimized aluminum and titanium content, enhancing its corrosion resistance and high-temperature stability.

A: Yes, various dimensions, finishes, and mechanical properties can be tailored to meet your application requirements.

A: Its strength and corrosion resistance make it ideal for industries like marine, oil & gas, nuclear, and chemical processing.

A: Carbide tools and robust lubrication systems are crucial to counteract work hardening. Precise feed and speed settings are also necessary.

A: Yes, it performs reliably up to 600°C but may require additional safeguards in oxidizing environments.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.