Get in touch with us

Leave a message

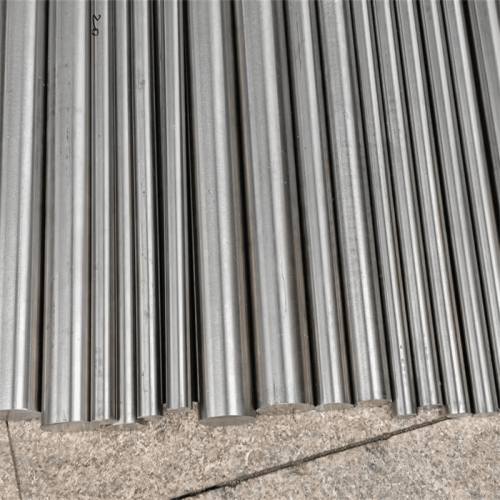

The Monel K500 Bar is a high-performance nickel-copper alloy known for its exceptional strength, corrosion resistance, and durability in extreme environments. This alloy builds on the properties of Monel 400 by adding aluminum and titanium, which enhance its mechanical performance without compromising its resistance to corrosive media. As a trusted Monel K500 Bar manufacturer in China, we provide premium-quality bars widely used in the marine, chemical, and oil and gas industries.

For the best pricing on Monel K500 Bar, we offer customized quotes tailored to your project requirements, ensuring competitive rates for price based on size, quantity, and delivery specifications.

Our Monel Bar stock is available in various sizes and finishes to meet diverse industrial needs. Below are the typical specifications:

Monel K500 Round Bar is a preferred material in industries requiring robust performance in harsh environments. Key applications include:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 63.0 min |

| Copper (Cu) | 27.0–33.0 |

| Aluminum (Al) | 2.3–3.15 |

| Titanium (Ti) | 0.35–0.85 |

| Iron (Fe) | 2.0 max |

| Manganese (Mn) | 1.5 max |

| Carbon (C) | 0.25 max |

| Sulfur (S) | 0.01 max |

| Property | Value |

|---|---|

| Tensile Strength | 1100 MPa (min) |

| Yield Strength (0.2% offset) | 790 MPa (min) |

| Elongation | 20% (min) |

| Hardness (Brinell) | 300 HB (typical) |

| Density | 8.44 g/cm³ |

Monel K500 Rod exhibits excellent resistance to a wide range of corrosive environments:

While Monel K500 Bar is highly versatile, certain limitations should be considered:

Monel K500 Rod provides outstanding resistance to various corrosive media:

We’ve been sourcing Monel K500 Rod from this China-based manufacturer for over two years. The quality is consistently excellent, and their Monel bar stock has performed flawlessly in our seawater applications.

John D.

Marine Engineer

Their Monel round bar exceeded our expectations for both durability and corrosion resistance. The team was very responsive with quotes and delivery timelines.

Sarah L.

Procurement Manager

We’ve been using Monel K500 Round Bar from this China-based manufacturer for our offshore drilling equipment, and the results have been outstanding. The material’s strength and corrosion resistance in harsh saltwater environments are exactly as promised. Their team also provided excellent support in helping us choose the right specifications for our needs. Highly recommend their Monel 500 round bar for any demanding application!

Michael T.

Operations Manager in Oil & Gas Industry

A: Monel K500 is a nickel-copper alloy with added aluminum and titanium, offering a unique combination of high strength, excellent corrosion resistance, and non-magnetic properties. Unlike Inconel, which is designed for extreme high-temperature applications, or Hastelloy, which excels in highly acidic environments, Monel K500 is ideal for marine and chemical processing applications where strength and seawater resistance are critical.

A: Yes, Monel K500 Bar maintains its mechanical properties and toughness even at sub-zero temperatures, making it suitable for cryogenic applications. However, we recommend consulting with our technical team to ensure it meets your specific requirements.

A: Our Monel K500 Bar complies with industry standards such as ASTM B865 and AMS 4676. Additionally, we provide material test certificates (MTC) with each shipment to ensure quality and traceability. If you require specific certifications for your project, please let us know, and we’ll work with you to meet those requirements.

A: Yes, Monel 500 round bar can be welded using TIG or MIG methods with matching Monel K500 filler metals. To avoid issues like cracking, ensure proper cleaning of the material before welding and consider post-weld heat treatment for stress relief. Our team can provide detailed welding guidelines upon request.

A: We offer Monel K500 Round Bar stock in various surface finishes, including hot rolled, cold drawn, polished, and custom finishes based on your requirements. Let us know your application, and we’ll recommend the best finish for optimal performance.

A: Monel K500 outperforms most stainless steels in high-salinity environments, such as seawater, due to its superior resistance to pitting and crevice corrosion. While stainless steel may corrode over time in such conditions, Monel K500 Bar maintains its integrity, making it a preferred choice for marine and offshore applications.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.