Get in touch with us

Leave a message

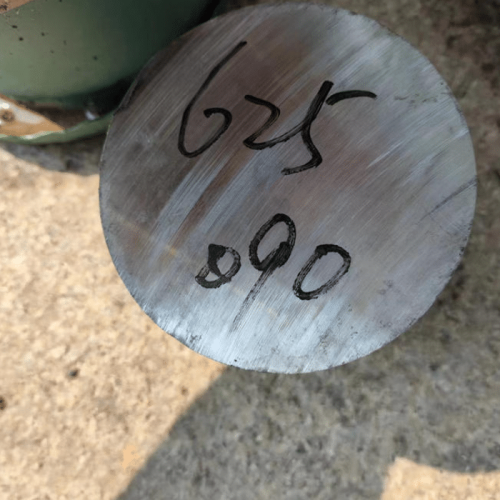

Need pricing for Inconel 625 Round Bar? Reach out to our sales team for a tailored quote. Costs vary by diameter, length, and order size—get your competitive offer now!

Our Inconel bar stock meets your exact needs!

| Element | Symbol | Weight % |

|---|---|---|

| Nickel | Ni | ≥ 58.0 |

| Chromium | Cr | 20.0 - 23.0 |

| Molybdenum | Mo | 8.0 - 10.0 |

| Niobium | Nb | 3.15 - 4.15 |

| Iron | Fe | ≤ 5.0 |

| Carbon | C | ≤ 0.10 |

| Manganese | Mn | ≤ 0.50 |

| Silicon | Si | ≤ 0.50 |

| Aluminum | Al | ≤ 0.40 |

| Titanium | Ti | ≤ 0.40 |

| Property | Units | Typical Value | Range |

|---|---|---|---|

| Tensile Strength | MPa | 930 | 827 - 1034 |

| Yield Strength (0.2% Offset) | MPa | 480 | ≥ 414 |

| Elongation | % | 42 | ≥ 30 |

| Hardness (Brinell) | HB | 220 | ≤ 290 |

| Hardness (Rockwell C) | HRC | 20 | ≤ 30 |

| Modulus of Elasticity | GPa | 207 | 204 - 211 |

| Density | g/cm3 | 8.44 | 8.42 - 8.46 |

| Fatigue Strength | MPa | 400 | 350 - 450 |

| Shear Strength | MPa | 600 | 550 - 650 |

| Shear Strength | MPa | 600 | 550 - 650 |

| Impact Toughness (Charpy V) | J (at 20°C) | 100 | ≥ 80 |

| Impact Toughness (Charpy V) | J (at -196°C) | 90 | ≥ 70 |

Inconel 625 resists chemicals effectively:

Avoid prolonged exposure to highly oxidizing acids.

Inconel 625 has some limits:

| Environment | Corrosion Rate (mm/year) | Resistance |

|---|---|---|

| Fresh Water | < 0.01 | Excellent |

| Salt Water (3.5% NaCl) | 0.02 - 0.05 | Excellent |

| Humid Air | < 0.01 | Excellent |

| Sulfuric Acid (15%) | 0.1 - 0.2 | Good |

| Hydrochloric Acid (5%) | 0.2 - 0.5 | Moderate |

Contact us for detailed corrosion resistance data specific to your application.

Liam F.

Aerospace Technician

Sara M.

Marine Engineer

Ethan K.

Oil & Gas Supervisor

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.