Get in touch with us

Leave a message

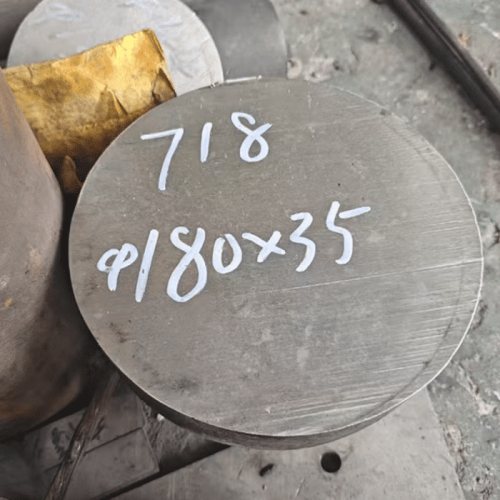

Want to price for Inconel 718 Round Bar? Contact our team for a custom quote. Costs vary by diameter, length, and volume—reach out today for competitive rates!

Our inconel bar stock is built to your specs!

| Element | Symbol | Weight % |

|---|---|---|

| Nickel | Ni | 50.0 - 55.0 |

| Chromium | Cr | 17.0 - 21.0 |

| Molybdenum | Mo | 2.8 - 3.3 |

| Niobium | Nb | 4.75 - 5.5 |

| Iron | Fe | Balance |

| Titanium | Ti | 0.65 - 1.15 |

| Aluminum | Al | 0.2 - 0.8 |

| Carbon | C | ≤ 0.08 |

| Manganese | Mn | ≤ 0.35 |

| Silicon | Si | ≤ 0.35 |

| Property | Value |

|---|---|

| Tensile Strength | 965 - 1100 MPa |

| Yield Strength | ≥ 550 MPa |

| Elongation | ≥ 30% |

| Hardness (Brinell) | ≤ 331 HB |

| Density | 8.19 g/cm3 |

Best in mixed corrosive-oxidative settings; less ideal in highly oxidizing acids.

| Environment | Corrosion Rate (mm/year) | Resistance |

|---|---|---|

| Fresh Water | < 0.01 | Excellent |

| Salt Water (3.5% NaCl) | 0.02 - 0.05 | Excellent |

| Humid Air | < 0.01 | Excellent |

| Sulfuric Acid (10%) | 0.1 - 0.3 | Good |

| Nitric Acid (10%) | 0.5 - 1.0 | Moderate |

Contact us for detailed corrosion resistance data specific to your application.

Sofia R.

Power Plant Operator

Tara L.

Aerospace Engineer

Jin H.

Oilfield Technician

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.