Get in touch with us

Leave a message

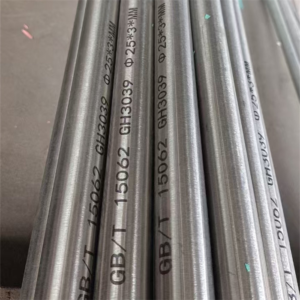

Nickel Alloy Pipes are engineered for exceptional performance, offering superior resistance to corrosion, high temperatures, and pressure in demanding industrial settings. As a leading manufacturer in China, our factory specializes in crafting Nickel Alloy Pipes and Tubes using high-grade nickel-based alloys blended with chromium, molybdenum, and other elements. These pipes surpass traditional materials like carbon steel in harsh environments, making them ideal for critical applications. Whether you need Seamless Pipe for aerospace or Nickel Alloy Tubes for petrochemical systems, our products deliver unmatched reliability and strength.

Nickel Alloy Pipes conform to rigorous standards and are available in various grades:

These specifications ensure each Nickel Alloy Pipe meets strict quality benchmarks, validated through industry-recognized testing protocols.

Nickel Alloy Pipes come in a wide range of dimensions, with options for customization:

This versatility makes Nickel Alloy Tubes suitable for both small-scale fittings and large piping systems.

Nickel Alloy Pipes are offered in various forms, produced with advanced techniques and finishes:

For instance, an Incoloy 800 (N08810) Seamless Pipe might be hot-rolled for heat resistance, while a Nickel Alloy Tube could be polished for enhanced corrosion protection.

| Grade | Key Features | Industry | Specific Uses |

|---|---|---|---|

| Incoloy 800 | High-temperature stability | Power Generation | Heat exchangers, furnace piping |

| Hastelloy C276 | Broad chemical resistance | Chemical, Petrochemical | Reactors, acid transfer lines |

| Inconel 600 | Oxidation resistance, strength | Aerospace | Turbine components, exhaust systems |

| Monel 400 | Seawater corrosion resistance | Marine, Oil & Gas | Offshore piping, pump shafts |

| Nickel 200 | Purity, corrosion resistance | Food Processing | Processing equipment, storage tanks |

A:Nickel alloy pipe, such as Inconel or Monel, is a corrosion-resistant, high-strength pipe made from nickel and other elements like chromium or copper, designed for extreme environments like chemical processing or marine applications.

A:Nickel alloy pipe is used in oil and gas for pipelines, chemical plants for reactors, and aerospace for exhaust systems, thanks to its resistance to corrosion, heat, and pressure.

A:Hastelloy is a type of nickel alloy pipe, but not all nickel alloys are Hastelloy. Hastelloy (e.g., C-276) has higher molybdenum for extreme acid resistance, while others like Monel focus on seawater durability.

A:Nickel alloy pipes, like Inconel 625, often outperform stainless steel in high-temperature strength and corrosion resistance, though stainless steel may be more cost-effective for less demanding uses.

A:Nickel alloy pipes have a density of 8.4-8.9 g/cm³, heavier than stainless steel (7.8 g/cm³). A 1m long, 50mm diameter pipe with 5mm thickness weighs around 5-6 kg, depending on the alloy.

A:Nickel alloy pipes are highly durable, resisting corrosion and wear in harsh environments. With proper maintenance, they can last 20-30 years in chemical or marine settings, even under high stress.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.