Get in touch with us

Leave a message

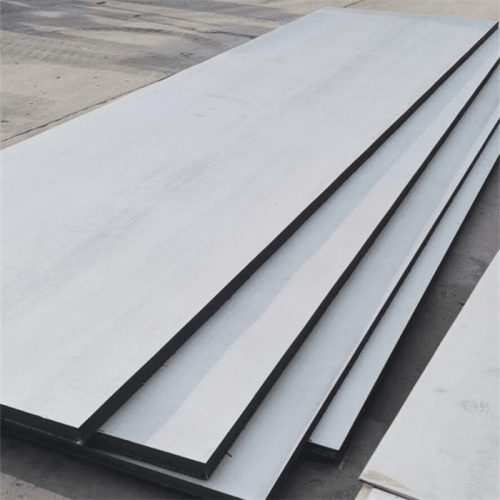

The GH3128 Nickel Based Alloy Plate is a high-temperature nickel-chromium alloy strengthened with tungsten and molybdenum, renowned for its excellent oxidation resistance and strength up to 950°C. Produced by expert factories in China, this alloy is designed for extreme environments. Whether you need GH3128 Nickel Alloy Plates, GH3128 Nickel Alloy Sheets and Plates, or GH3128 Plate, it delivers top-tier performance in critical applications.

Our Nickel Based Alloy Plate comes in various configurations:

Need specific Nickel-based Alloy Plate specs? Our China factory offers tailored solutions!

The GH3128 Alloy Plate serves high-temperature industries:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | Balance |

| Chromium (Cr) | 19.0–22.0 |

| Tungsten (W) | 7.5–9.0 |

| Molybdenum (Mo) | 7.5–9.0 |

| Iron (Fe) | ≤ 2.0 |

| Aluminum (Al) | 0.4–0.8 |

| Titanium (Ti) | 0.4–0.8 |

| Silicon (Si) | ≤ 0.8 |

| Manganese (Mn) | ≤ 0.5 |

| Carbon (C) | ≤ 0.05 |

| Phosphorus (P) | ≤ 0.015 |

| Sulfur (S) | ≤ 0.015 |

| Property | Value |

|---|---|

| Tensile Strength | 900–1100 MPa |

| Yield Strength (0.2%) | ≥ 500 MPa |

| Elongation | ≥ 25% |

| Hardness (Brinell) | 250–350 HB |

| Density | 8.24 g/cm³ |

The GH3128 Alloy Plate resists:

Our China distributor can suggest alternatives if needed.

This suits GH3128 Nickel Alloy Plates for high-temperature and marine use.

Welding GH3128 Nickel Alloy Plate requires precision:

Tips:

Our China factory offers pre-processed GH3128 Nickel Based Alloy Plate options.

James L.

Aerospace Engineer

Sarah T.

Power Plant Manager

Mike P.

Industrial Technician

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.