Get in touch with us

Leave a message

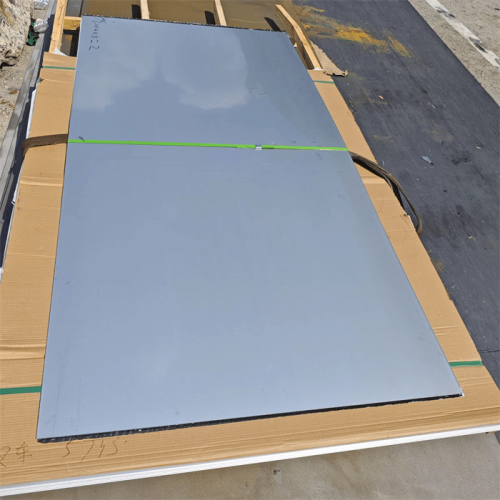

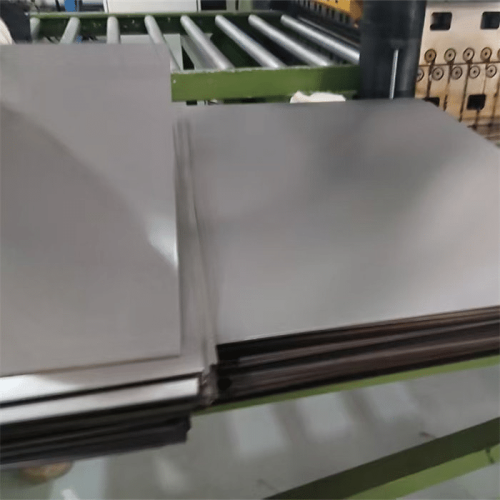

Our Inconel 625 Plate comes in various configurations:

The Inconel 625 Plate serves a wide range of industries:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 58.0 min |

| Chromium (Cr) | 20.0–23.0 |

| Molybdenum (Mo) | 8.0–10.0 |

| Iron (Fe) | ≤ 5.0 |

| Niobium (Nb) | 3.15–4.15 |

| Cobalt (Co) | ≤ 1.0 |

| Manganese (Mn) | ≤ 0.5 |

| Silicon (Si) | ≤ 0.5 |

| Carbon (C) | ≤ 0.10 |

| Phosphorus (P) | ≤ 0.015 |

| Sulfur (S) | ≤ 0.015 |

| Property | Value |

|---|---|

| Tensile Strength | 760–1000 MPa |

| Yield Strength (0.2%) | ≥ 345 MPa |

| Elongation | ≥ 30% |

| Hardness (Brinell) | 150–220 HB |

| Density | 8.44 g/cm³ |

The Inconel 625 Plate resists:

The Inconel 625 Plate has few constraints:

Our China distributor can suggest alternatives if needed.

Welding Inconel 625 Plate is efficient:

Tips:

Lisa R.

Marine Technician

Mark P.

Oil & Gas Lead

James T.

Aerospace Engineer

A: Yes, Inconel 625 Sheet offers excellent resistance to saltwater corrosion, making it ideal for marine applications like 625 Nickel Alloy Sheets and Plates. Our China manufacturer ensures top performance in harsh conditions!

A: The Inconel 625 Sheet excels up to 1000°C, maintaining strength and corrosion resistance. It is perfect for Incoloy 625 Plate in aerospace or power generation—ask our China factory for specifics!

A: 625 Nickel Alloy Plates outperform stainless steel in corrosion resistance and high-temperature strength, thanks to nickel and molybdenum. For Inconel 625 Sheet, it’s a premium choice – contact our China distributor for guidance!

A: Absolutely, Incoloy 625 Plate resists a wide range of acids and corrosive chemicals, making it a go-to for Inconel 625 Sheet in chemical plants. Our China enterprise delivers tailored solutions!

A: Yes, our 625 Nickel Alloy Plate Rolling process allows custom shaping and sizes for Inconel 625 Sheet. Reach out to our China factory to discuss your needs!

A: Shipping times for Inconel 625 Plate depend on order size and location, but our China manufacturer prioritizes fast delivery – get in touch for an accurate lead time!

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.