Stainless steel is a remarkable material used from as basic as kitchen utensils to infrastructure for a durable and long-lasting construction. This article will discuss the other properties that make stainless steel valuable, including corrosion resistance, strength, aesthetic appeal, and recyclability. With the help of these characteristics, the articles aim to make clear why stainless steel is so well-liked. With the development of increasing these controllable parameters, we want to realize how these pretentious materials continue to perform and function in various conditions. Join us as we uncover the secrets behind this extraordinary alloy.

What are the Physical Properties of Stainless Steel?

Stainless steel is considered one of the most versatile alloys because of its unique physical properties. The simplest one – corrosion resistance – exists thanks to chromium, which forms an oxide layer on stainless steel’s surface. Its high strength and toughness further make it capable of resisting high temperature and pressure. In this sense, the stainless steel surface is smooth, polished, multifunctional, and appealing for decorative use. Lastly, its resistance to wear makes it usable across a wide range of industries.

Understanding the Key Properties of Stainless Steel

The exceptional corrosion resistance of stainless steel is due to its chromium content, which reacts with oxygen to form a passive layer that protects the steel from moisture and oxidizing substances. It is both polished and modern, making the material suitable for functional and decorative purposes. Its strength and durability also make it usable in harsh environments. Moreover, stainless steel, being versatile, low-maintenance, and sustainable, is an essential material used across various industries. Further, the aesthetic of the metalliferous material increases its value, making it more common in numerous applications worldwide.

Exploring the Magnetic Properties of Stainless Steel

The magnetic characteristics of stainless steel rely primarily on its microstructure. Based on crystalline structure, stainless steels are divided into four categories – austenitic, ferritic, martensitic, and duplex stainless steels. The following list presents ferromagnetism and its absence in order:

- Austenitic Stainless Steels are known as non-magnetic with face-centered cubic (FCC) growth. They may acquire feeble magnetism by cold working or deformation. Notable types are 304 and 316, which are noted for their inexcusably low magnetic permeability (µ) values of ~1.05.

- Ferritic Stainless Steels—These possess a body-centered cubic (BCC) structure and are known to be magnetic. Grade 430 is one example. Its strong magnetic properties are coupled with higher permeability, making it ideal for operations that require magnetism.

- Martensitic Stainless Steels- Like duplex stainless steels, these are also magnetic because of their BCC structure and higher carbon content. Typical examples are 410 and 420.

- Duplex Stainless Steels- Known to contain two phases, ferritic and austenitic, the duplex grade 2205 has an excellent combination of strength and corrosion resistance. It’s moderately magnetic because of its ferritic character.

Relative permeability and material composition, among other key parameters, greatly influence stainless steel’s magnetic properties. These considerations enable the appropriate selection within the functional and technical spectrum of stainless steel types.

How Stainless Steel is Resistant to Corrosion

The chromium content within stainless steel is one of the most critical factors detailing the steel’s resistance to corrosion. Chromium forms a passive layer of chromium oxide on the steel surface that protects it from further oxidation when exposed to oxygen. This layer covers the steel’s surface and protects it from moisture and oxygen, possibly leading to the steel corroding. Stainless steel corrosion resistance improves with increased chromium, with the minimum requirement being 10.5%.

Alloying elements like nickel and molybdenum also improve corrosion resistance in varying environments. For instance, including 2-3% molybdenum bolsters resistance to pitting and crevice corrosion in chloride-rich areas. Nickel also aids general corrosion resistance and contributes to stabilizing the austenitic grade. Meanwhile, nitrogen improves mechanical strength while assisting in preventing localized corrosion.

Corrosion resistance factors include:

- The lower limit of chromium content is 10.5%, with increments that improve protection against corrosion.

- Molybdenum content: 2-3% improves resistance to corrosion from chlorides.

- Nickel content: Around 10% in austenitic grades, 8% further improves resistance.

- Surface finish: Better finishes have a smoother surface, and corrosive materials are less likely to start corrosion.

- Operating temperature: Corrosive environments with higher temperatures can be destructive to the passive layer of the stainless steel.

Stainless steels, 304 and 316, for example, are widely accepted owing to their favorable combination of resistance to corrosion and value. Grade 316 performs best in marine and chemically aggressive environments because of its molybdenum content. The passive layer can also be maintained over time through regular cleaning and other forms of maintenance to remove deposits.

How do the Mechanical Properties of Stainless Steel Affect its Use?

Stainless steel has versatile mechanical properties, such as strength, ductility, toughness, and corrosion resistance, enabling the material to be used in various applications. It is ideal for structural components and load-bearing applications owing to its high tensile strength whilst being easily fabricated due to its ductility. The toughness of stainless steel also ensures its durability under impact or extreme conditions for construction, automotive, and aerospace. These features make stainless steel reliable for use in demanding environments, along with its corrosion resistance property.

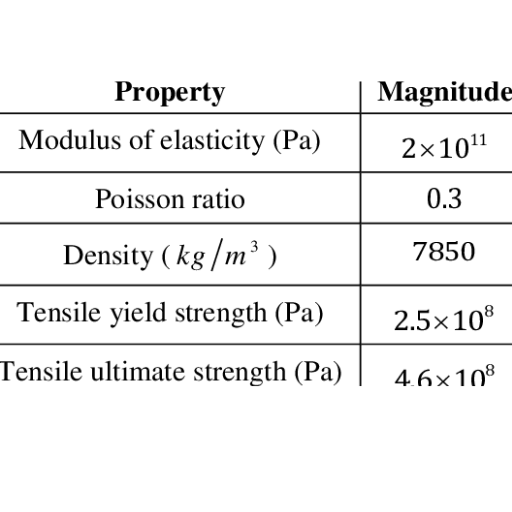

Comparing Mechanical and Physical Properties

Upon examining the mechanical and physical properties, it is clear that mechanical properties like strength, toughness, and ductility determine how a material responds to external forces or stresses. These features include tensile strength, hardness, and impact resistance, which are fundamental for structural and overall durability. Through another lens, physical properties such as density, thermal conductivity, and electrical resistivity govern how a material engages with the environment, for example, the ability to conduct heat or corrosion. The combination of both property sets enables the material to be selected according to the application requirements with a focus on performance and reliability.

The Role of Composition of Stainless Steel in Its Strength

The strength and performance of stainless steel depend on its composition. I think the right amounts of chromium, nickel, molybdenum, and carbon are essential. Typically, Chromium is above 10.5%. It provides corrosion resistance by creating a passive chromium oxide layer. Nickel increases ductility and toughness, and molybdenum improves overall strength, especially in harsher environments. Moreover, carbon contributes to hardness and tensile strength in smaller amounts but must be managed to limit brittleness in specific grades.

Key Technical Parameters:

- Chromium (Cr): ≥10.5%

- Nickel (Ni): 8-12% (varies by grade)

- Molybdenum chromium resistant (Mo): 2-3%

- Carbon (C): Generally <0.1%

- Tensile Strength: 515 MPa for common grades and >1,000 MPa for high-performance alloys.

These parameters affect stainless steel’s reliability and versatility, enabling it to be used in various industries, including aerospace and construction.

What Makes 304 Stainless Steel Unique?

The best combination of corrosion resistance, durability, and cost is found in 304 searine, making it stand out. High chromium (18%) and nickel (8-10%) enable it to resist oxidation and rust, which means it can be used in areas prone to moisture or even mild chemicals. In addition, 304 stainless steel is highly versatile, which means it has good formability and weldability, making it suited for other applications like kitchen equipment, chemical containers, and architectural panels. Its properties make it one of the most dependable types of stainless steel, giving it the edge over others.

Characteristics of 304 and 316 Stainless Steel

The most significant difference between 304 and 316 stainless steel is the elemental composition and the degree of their corrosive nature. The presence of molybdenum in 316 stainless steel dramatically increases its resistance to chlorides, salts, and hostile conditions, which makes it suitable for chemical or marine applications. Conversely, 304 stainless steel is well-known for its good all-around performance in less corrosive environments and has good strength, formability, and price. For applications involving salt water or chemicals, I would recommend using 316 stainless steel. For routine use, such as household appliances and food processing equipment, 304 stainless steel should be adequate. Both are good options, but the choice should depend on the application’s specific environmental and functional conditions.

The Benefit of Stainless Steel in High-Temperature Applications

Because of its high heat, strength, and corrosion resistance, stainless steel is preferred in high-temperature applications. While 316 stainless steel can resist scaling to up to 925°C (1700°F), grade 304 can do so at 870°C (1600°F). For even higher temperatures, specialized grades like 310 stainless steel can withstand sustained exposure up to 1150°C (2100°F). Scaling and oxidation, along with structural integrity, are effortlessly performed by stainless steel in extreme conditions, such as heat exchangers, furnaces, and industrial ovens. Moreover, the mechanical properties of stainless steel enable it to withstand oxidation while preserving safety and reliability in thermal exercises.

How Do Different Grades of Stainless Steel Compare?

Each type of stainless steel has specific requirements to fulfill, and they differ by composition, corrosion resistance, strength, and heat resistance. For example, grade 304 austenitic steels are considered stainless steel because kitchens and pipelines are fabricated using them, and their corrosion resistance is excellent. Moreover, kitchenware does not require much fabrication, making it easier to make it out of 304-grade stainless steel. Grade 410 martensitic steels, on the other hand, are much stronger and more complex but are also weaker in terms of oxidation resistance. This grade sits well below 304 but is often used for kitchen knives and working pedals. Duplex steels are the middle point between austenitic and ferritic and have higher strength and better corrosion resistance than the former. At the same time, they are more expensive but better for marine and chemical applications. Each application requires a different grade based on heat, pressure, and corrosive elements, so picking one is always challenging.

An Overview of Austenitic, Ferritic, and Martensitic Stainless Steel

Austenitic Stainless Steel

Type 316 and 304 stainless steel are part of the austenitic stainless steel family, which is highly versatile and commonly used because of its high resistance to corrosion, good formability, and weldability. It is typically non-magnetic when annealed and contains around 16- 26% chromium and 6-22% nickel. It is often used in food processing, chemical equipment, and medical tools. Technical Parameters: It has a tensile strength of 515 to 750 MPa and can maintain strength and ductility up to 870 degrees Celsius.

Ferritic Stainless Steel

Ferritic stainless steel is characterized by being magnetic, having good resistance to stress corrosion cracking, and being moderately resistant to corrosion. It tends to have low carbon content and 10.5-18% chromium. Common grades like 430 and 409 apply to automotive exhaust systems, decorative trim, and kitchen appliances. Technical Parameters: It has a tensile strength of 400-550 MPa, which makes it suitable for moderately corrosive environments and up to 750 degrees Celsius.

Martensitic Stainless Steel

Martensitic stainless steel is globally recognized for its hardness and strength. However, it has lower corrosion resistance than austenitic or ferritic types. It contains 12-18% chromium and some carbon, which makes it suitable for cutlery, surgical instruments, and industrial tools. It can withstand temperatures as high as 600°C, while its tensile strength depends on heat treatment and ranges from 500 to 1500 MPa.

Key Considerations for Selection

Choosing a grade of stainless steel depends on its operating temperature, exposure to corrosive elements, and required mechanical strength. Austenitic grades are preferable when high corrosion resistance is desired, while ferritic and martensitic grades are more suited for high-strength applications where cost efficiency is also essential.

The Corrosion Resistance Across Various Grades

Corrosion resistance differs significantly between stainless steel grades. Austenitic grades like 304 and 316 are the best types because of their high amounts of chromium and nickel, with 316 grade being the best due to its resistance against chlorides and marine environments. Grade 430 provides moderate ferritic stainless steel resistance but comes at a lower price. Grade 410 is a martensitic grade with lower resistance to corrosion because the design focuses on strength and hardness, not corrosion exposure. Each grade should be carefully chosen based on the specific environment and application.

Identifying the Right Grade of Stainless Steel for Your Needs

My main focus while choosing the correct grade of stainless steel is the operational context and environmental conditions surrounding my purpose. For regions suffering from corrosion, such as the chemical or marine industry, an austenitic grade, such as 316, due to added molybdenum and higher corrosion resistance. For moderate-risk applications, ferritic grade, e.g., 430, offers adequate resistance at a low cost, making it much more economically reasonable. If my goals are focused on strength and resistance to wear, martensitic 410 is an excellent option for tools and machines, but it lacks corrosion resistance.

Here are some key features to keep in mind for the proper selection

- Corrosion Resistance: 316 is ideal for chloride regions, while ferritic grades may work in dry areas.

- Mechanical Strength (e.g., Yield Strength): Hard-wearing and challenging applications tend to be martensitic.

- Temperature Range: Both low and high temperatures are managed exceptionally well with austenitic steels.

- Cost Effectiveness: 430 yields good value at low cost and has average corrosion resistance.

Making the final decision in selecting a grade requires a precise balance of performance, environmental conditions, and how much you are willing to pay.

What Are the Chemical Properties of Stainless Steel?

Stainless steel is mainly made of iron and chromium, but it also includes other elements like nickel, molybdenum, and manganese, which give it many valuable traits. The defining feature of stainless steel is its chromium content of usually 10.5%, which allows it to corrode passively due to having a passive oxide layer on the surface. Nickel further protects from corrosion and assists with toughness, while molybdenum increases resistance to pitting and crevice corrosion. Different grades have different compositions, allowing for greater variety in specific applications and environments.

The Role of Carbon Steel and Other Elements

Due to its cost-effectiveness, carbon steel is extremely useful in various industries because of its strength and durability. Unlike stainless steel, carbon steel contains higher levels of carbon – usually up to 2.1%. This increases hardness and tensile strength but lowers corrosion resistance. Carbon content determines the classification into low, medium, or high carbon steel which is useable in construction, automotive components, or tools industry. Other elements such as manganese improve wear and toughens resistance, while sulfur and phosphorus, although impurities, can enhance machinability if used in small amounts. These elements allow carbon steel to be tailored for various environments and industrial performance demands.

How Chemical Properties Influence Stainless Steel’s Performance

The operation of stainless steel is particularly affected by its chemical components, mainly chromium, nickel, and molybdenum. Chromium (in most cases above 10.5%) is an essential part of the alloy as it provides resistance against rusting due to the passive oxide layer that it forms on the surface, stopping any oxidation processes. Nickel improves ductility and toughness, allowing the steel to be more easily fabricated and resist impacts. Molybdenum increases the resistance against pitting and crevice corrosion, especially in environments with high concentrations of chlorides.

Technical details encompass the following ordinary values:

Chromium: 10.5% to 30% (for formation of alloy and its oxide layer corrosion resistant).

Nickel: From 8% to 14% for austenitic stainless steels (for formability and toughness)Austentic.

Molybdenum: For stainless steel grades 2% to 6% in marine (for resistance against chloride)

Adjusting these components can alter stainless steel grades to suit specific needs. Some of these applications are food processing, marine conditions, or construction.

References

- Stainless Steel Characteristics & Properties – Eagle Tube

- Stainless Steel Properties, Grades, and Applications – Alroys

- Stainless Steel – Wikipedia

Frequently Asked Questions (FAQ)

Q: What are the key properties of stainless steel?

A: Stainless steel’s properties include corrosion resistance, strength, durability, and aesthetic appeal. Its versatility makes it superior for a wide range of applications.

Q: What are the different types of stainless steel?

A: The different types of stainless steel include austenitic stainless steel, ferritic stainless steel, duplex stainless steel, and other variations like martensitic stainless steel. Each type has unique characteristics.

Q: What is austenitic stainless steel?

A: Austenitic stainless steel is the most common type, known for its excellent corrosion resistance and formability. This type of stainless steel is highly favored in industries for its non-magnetic properties and ability to be cold-worked.

Q: How does ferritic stainless steel differ from austenitic?

A: Ferritic stainless steel is magnetic and generally has lower corrosion resistance than austenitic stainless steel. It is used in applications where high strength and low cost are desired, such as automotive and industrial equipment.

Q: What is duplex stainless steel, and where is it used?

A: Duplex stainless steel combines the properties of austenitic and ferritic stainless steels, offering high strength and excellent corrosion resistance. Due to its superior performance, it is commonly used in the chemical, oil, and gas industries.

Q: What are the typical applications of stainless steel?

A: Stainless steel is used in many industries. It is used in kitchenware, medical instruments, construction, automotive, and aerospace due to its durability, aesthetic qualities, and rust resistance.

Q: How does the stainless steel grade affect its properties?

A: Stainless steel grades, such as grade 304, determine the specific properties of the steel, like corrosion resistance and strength. The American Iron and Steel Institute and the British Stainless Steel Association provide guidelines on these grades to ensure quality and performance.

Q: Why is stainless steel considered superior to mild steel?

A: Stainless steel is superior to mild steel due to its enhanced corrosion resistance, strength, and long life span. It requires less maintenance and offers more aesthetic finishes.

Q: How does the International Stainless Steel Forum contribute to stainless steel production?

A: The International Stainless Steel Forum provides data, research, and insights into global stainless steel production, helping manufacturers improve processes and develop new steel products.

Q: What characteristics of stainless steel make it highly versatile?

A: Stainless steel is highly versatile due to its corrosion resistance, strength, formability, and range of finishes. These characteristics allow it to be used in various products and industries, from household items to industrial machinery.