Stainless steel remains popular due to its incredible strength, resistance to corrosion, and durability across various spheres, including construction and healthcare. Deriving from differing manufacturers, not all grades of stainless steel are equal, so knowing differences can be beneficial in choosing the right one for your specific purpose. Two such designations that explain this confusion are S30408 and 304. They may seem similar at first, but something as subtle as a differentiating part of a composition or properties reveal their advantages. This blog post will highlight the differences between S30408 and 304 stainless steel so that you are better suited choosing for your products or projects. The science, applications, and advantages of these two grades await in the rest of the article.

What is S30408 Stainless Steel?

S30408 is a form of stainless steel marked S30408 in Europe which is equal to 304 stainless steel in USA, with some particular criteria for manufacturing and chemical composition. It is an austenitic stainless steel, well known for its corrosion resistance, durability, and versatility. S30408 is balanced in nickel and chromium, thus being very resistant to rust and oxidation in several environments. This grade is instrumental in construction, food processing, and chemical equipment due to its reliability and performance under different conditions.

Understanding Chemical Composition

The mechanical properties of S30408 stainless steel are proportionally prepared to make sure that they can perform in different industries without fail. The alloy’s notable constituents are chrome 18-20%, and nickel 8-10.5%. Together, they increase resistance to corrosion and oxidation. Furthermore, the compound possesses an alkaline or acidic environment combined with manganese ≤2%, silicon ≤1%, and phosphorus ≤0.045%, reinforcing the structure. Corrosion resistance is maintained with a trace amount of sulfur ≤0.03% and carbon ≤0.08%, enhancing machinability.

Adding high chromium in chrome plating 304 stainless steel creates a guaranteed rust resistant surface, improving life expectancy under challenging conditions. Nickel improves alloy flexibility and makes it more challenging, causing it to be used in applications where both strength and flexibility are essential. Balance of these elements makes S30408 a popular alloy for food processing, chemical plants, and even architecture, where environmental changes are a concern.

Below is a summary table of the typical chemical composition of S30408:

| Element | Percentage (%) |

|---|---|

| Chromium (Cr) | 0 – 20.0 |

| Nickel (Ni) | 0 – 10.5 |

| Manganese (Mn) | ≤ 2.0 |

| Silicon (Si) | ≤ 1.0 |

| Carbon (C) | ≤ 0.08 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.03 |

This combination makes S30408 highly reliable for environments requiring superior resistance to moisture, heat, and chemicals.

Mechanical Properties of S30408

| Property | Value |

|---|---|

| Tensile Strength | ≥ 520 MPa |

| Yield Strength | ≥ 205 MPa |

| Elongation | ≥ 40% |

| Hardness | ≤ 187 HBW |

| Modulus of Elasticity | ~193 GPa |

| Impact Resistance | High |

| Corrosion Resistance | Excellent |

| Weldability | Excellent |

| Thermal Conductivity | 16.3 W/(m·K) at 100°C |

| Applications | Automotive, kitchen, medical |

Corrosion Resistance in S30408

| Key Point | Details |

|---|---|

| Material Type | Austenitic stainless steel |

| Corrosion Resistance | Excellent in oxidizing and reducing environments |

| Chemical Composition | 18-20% Chromium, 8-11% Nickel, ≤0.08% Carbon |

| Resistance to Chlorides | Good resistance to chloride-containing solutions |

| Heat Resistance | Maintains strength and corrosion resistance at high temperatures |

| Weldability | High, with reduced risk of intergranular corrosion |

| Applications | Food processing, automotive, architectural, and industrial uses |

| Passivation Layer | Enhanced by chromium content, improving oxidation resistance |

| Standards | GB/T 20878 (China), equivalent to ASTM 304 |

Exploring 304 Stainless Steel

The food industry requires 304 stainless steel due to its fantastic versatility, superb resistance to corrosion and rust, and durability over time. 304 stainless steel is an alloy of iron, nickel, and chromium, creating a protective layer and allowing for minimal oxidation and corrosion. These features favor construction, manufacturing automotive parts, and food processing.

An international standard such as ASTM 304 increases trust within various industries and enables operations on a larger scale, which also increases demand. It is also notable for ease of welding and fabrication and strong resistance to several chemical elements and very high temperatures.

Key Chemical Composition

304 stainless steel is a ferrous alloy that is regarded for its versatile application of usage, ranging from household appliances to jet engines, due to its high tensile strength and resistance against corrosive elements. This is possible due to its unique composition, which comprises:

Chromium (Cr): 18.0 – 20.0%

It increases the passive layer strength of chromium oxide, which bolsters the steel against corrosion and further protects it from chemical breakdown, thus protecting its structural integrity.

Nickel (Ni): 8.0 – 10.5%

The presence of nickel improves the mechanical properties by increasing toughness, ductility, and weldability while also showing remarkable steel compatibility for acidic and marine conditions.

Carbon (C): ≤ 0.08%

Due to the exceedingly low carbon content, there is a very low chance of intergranular corrosion and reduction of carbide precipitate during welding.

Manganese (Mn): ≤ 2.0%

Manganese becomes a alloying element in steel to enhance its mechanical almong workability, yield, and tensile strength resulting in improved brittle fracture.

Silicon (Si): ≤ 0.75%

Consequently helps in protecting the base alloyed from oxidation at increased temperatures.

Phosphorus (P): ≤ 0.045%

Maintaining a low percentage ensures mechanical strength in the steel, protecting it from becoming brittle.

Sulfur (S): ≤ 0.030%

In trace amounts, sulfur helps improve the steel’s ability to withstand corrosion while also giving it some protective strength against becoming brittle.

Iron (Fe): ~70%

Iron contains the base alloy in composition, giving the steel its fundamental rigidity and framework to form 304 stainless steel.

This accurate composition enables 304 stainless steel to perform exceptionally well in different domains, ranging from food-grade equipment to structural work susceptible to corrosion. This versatility means 304 stainless steel is a dependable material in numerous industries.

Assessing Mechanical Properties

304 stainless steel has exceptional mechanical properties, a tensile strength of roughly 515 MPa, and reasonable ductility, making it useful in applications requiring flexibility, durability, and high endurance.

Impact of Carbon Content

The performance and applications of 304 stainless steel greatly depend on the carbon content. In my opinion, higher levels of carbon strengthen and harden materials, but may weaken corrosion resistance because of carbide precipitation. This balance is critical, particularly in settings that require strong durability and rust resistance.

How Does S30408 vs 304 Compare?

Both 304 stainless steel and S30408 are regarded as the same grade, with S30408 being the name under ASTM and ASME standards. Both materials provide outstanding corrosion resistance and have high strength and tough mechanical properties. The difference is mainly in the use of these designations, where S30408 is much more common in places with stringent engineering standards and codes. Otherwise, these two designations can work for most practical purposes.

Difference Between S30408 and 304

| Feature | S30408 | 304 Stainless Steel |

|---|---|---|

| Standard | GB/T 20878 | ASTM A240 / AISI 304 |

| Carbon Content | ≤ 0.03% | ≤ 0.08% |

| Nickel Content | 8–12% | 8–10.5% |

| Chromium Content | 18–20% | 17.5–19.5% |

| Corrosion Resistance | Slightly better in harsh conditions | Excellent general resistance |

| Weldability | Superior, no post-weld treatment | Good, may need post-weld treatment |

| Applications | High-temp, welded structures | General-purpose, food, medical |

| Cost | Slightly higher | Relatively lower |

Comparing Corrosion Resistance

The ease of corrosion for S30408 and 304 is one of the main reasons these materials are so deeply utilized in various fields and industries, especially regions facing moisture, chemicals, and high humidity. Here are five primary factors that determine and showcase their properties against corrosion resistance:

- Chemical Composition

The excellent corrosion resistance of both S30408 and 304 can be attributed to their high chromium (approximately 18-20%) and nickel (8-10%) levels, which are especially applicable to conditions of oxidation and rust in atmospheric settings.

- Pitting Corrosion Resistance

Both grades with chromium characteristics exhibit strong resistance to pitting corrosion inflicted by chloride ions. This makes them suitable for marine settings or applications involving salts and chemicals.

- Intergranular Corrosion

Both materials are intergranular corrosion resistant when adequately treated. However, adversity stress-relief annealing processes provide greater stability in boundary attack environments.

- Environmental Performance

Both materials demonstrate good performance in acidic or basic environments. Their features are perfect for operation in processing industries dealing with sulfuric or nitric acid.

- Passivation Layer

This self-repairing layer is great even after minor surface damages. Therefore, both grades are capable of naturally creating a passive oxide layer that performs superbly in hostile conditions, protecting them from corrosive factors.

In general, both S30408 and 304 perform well in terms of corrosion resistance. Their comparable performance makes these materials dependable for applications requiring durability and environmental degradation resistance.

Comparative Weldability

Both grades have good attributes when studying the weldability of S30408 and 304 stainless steel, although some details may alter their effectiveness in welding.

- Ease of Welding

Both S30408 and 304 are austenitic stainless steels and this classification possesses moderate welding features attributable to their low carbon content and high ductility. These factors lessen the chances of crack formation during the welding process. Standard welding techniques like TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) are readily accessible for both grades and they offer uniform outcomes.

- Heat-Affected Zone (HAZ)

The zone of thermal moderation is of tactical importance when it comes to burning. In the case of both S30408 and 304, the likelihood of precipitate carbide formation in HAZ is about the same, especially with combustible high temperatures for a long duration between 800 – 1500°F (427 – 815°C). This leads to sensitization and decreased corrosion resistance, notably in chloride-ion-rich regions. Some low-carbon versions, such as 304L, or proper post-weld treatments, are employed to alleviate the problem.

- Treatment of Welded Joints

To maximize the benefits for both grades, post-weld treatments, specifically annealing, are often needed to restore corrosion resistance and relieve residual stresses. For extreme environmental applications, passivation of the weld zones becomes essential in preserving the continuity of the passive oxide layer. Coruña bites resulting in localized corrosion due to the lack of treatment will compromise the entire structural performance of the welded entity.

- Weld Strength and other parameters

Industry and material research have recorded the tensile strength of welded joints of S30408 and 304 to be about the same within the range of 515 – 730 MPa for the different metrics of welding conditions, filler materials, and other factors. Ductility and toughness of the resulting welds of both grades remain high, making it feasible to use in structural applications of numerous industries such as chemical processing, power generation, and construction, reliably.

- Compatibility of filler metallic materials with other non-ferrous metals

The strength of the weld joint is directly proportional to the filler material selected, making selection critical. S30408 and 304 require austenitic fillers, preferably ER308 or ER308L for practical welding. Widening gaps is closed through fillers of different composition and aids in welding joint formation.

Both S30408 and 304 stainless steels possess remarkable weldability, which is applicable to numerous commercial and industrial processes. Understanding particular parameters like the operating environment and the welding technique is crucial for maximizing efficiency and durability.

Applications of S30408 and 304 Stainless Steel

| Application Area | S30408 | 304 Stainless Steel |

|---|---|---|

| Food & Beverage | Tanks, piping, cookware | Food processing, brewing, milk equipment |

| Medical Devices | Surgical tools, trays | MRI-compatible equipment |

| Construction | Structural components, handrails | Roofing, cladding, doors, windows |

| Automotive | Exhaust systems, engine parts | Decorative trims, structural components |

| Chemical Processing | Storage tanks, valves | Pipes for mild corrosive chemicals |

| Aerospace | High-temperature components | Lightweight structural parts |

| Consumer Goods | Kitchen sinks, appliances | Durable goods, fasteners |

| Architectural | Façades, railings | Interior fittings, exterior cladding |

| Heat Exchangers | High-efficiency heat transfer | General-purpose heat exchangers |

Utilization in Steel Plates and Sheets

The various stainless steel grades 304 and S30408 are famous for steel plates and sheets because of their versatile applications, corrosion resistance and mechanical strength. Their features make these alloys preferable for industrial applications that require sufficient hereby and durability. Below are some of the most common uses of the two grades:

- Chemical and Petrochemical Industry

- Due to corrosive chemicals, S30408 and 304 stainless steel plates and sheets are used to construct chemical storage tanks, reaction vessels, and heat exchangers.

- Data indicates that in typical industry acidic environments, these alloys suffer less than 0.01 mm/year of corrosion, highlighting their reliability.

- Food and Beverage Processing

- Used for machinery parts, food processing surfaces, eating containers, and storage vessels, it ensures food safety.

- The non-reactive surface ensures no contamination, and operations are done under hygienic conditions.

- Construction and Architecture

- Used for manufacturing cladding panels, modern structural sheet roofing, as well as parts of modern buildings.

- Thanks to stainless steel’s resilience against exposure to weather conditions, long-term performance is ensured.

- Automotive and Transportation

- Used in making exhaust systems, frames of automobiles, and components of railways which are exposed to high temperatures and strong oxidizing conditions.

- Studies from ASTM conclude that the use of stainless steel in transportation equipment enhances its life span by 30%.

- Marine and Coastal Uses

- Perfect for ship construction, piers, offshore facilities as they withstand salt water corrosion.

- Research indicates no significant pitting after long-term exposure to corrosive environments.

These uses show how 304 stainless steel can be used in many different areas due to its ability to perform well under tough conditions.

Role in Stainless Steel Pipe Manufacturing

The unmatched versatility, durability, and corrosion resistance of grade 304 stainless steel makes it crucial for the manufacturing processes of stainless steel pipes. This alloy is especially used for pipes due to its high mechanical strength and the ability to withstand extreme environmental conditions.

Recent statistics indicate that grade 304 stainless steel accounts for more than 40% of stainless steel pipe production around the world due to its low cost and dependability. The ease of welding allows the production of both seamless and welded pipes, which serve the oil and gas, chemical processing, and water treatment industries. Also, 304 stainless steel’s nickel content means long-term exposure in humid and moisture-rich surroundings can be sustained without rust or corrosion, critical for durability and performance.

Modern automation techniques like automatic TIG welding and laser welding have greatly benefited stainless steel pipe production, increasing manufacturing efficiency. These methods provide accurate construction with very little material loss while preserving the integrity of the 304 alloy. Furthermore, pipes made from 304 stainless steel comply with global standards such as ASTM A312, guaranteeing quality and reliability regardless of the application.

The importance of 304 stainless steel in the pipe manufacturing industry is clearly evident. Its ability to deliver reliable performance while simultaneously considering eco-friendly production methods is essential in meeting the ever-increasing needs of various industries.

Common Usage in Chemical Processing

I often find 304 stainless steel pipes invaluable in chemical processing because of their exceptional resistance to corrosion, even when exposed to aggressive chemicals at high temperatures. These pipes are particularly suited for the transport of corrosive materials, and also in heat exchangers, storage tanks, and reaction vessels. Their strength and compliance with international standards make them ideal for corrosion resistance, safety, and efficiency in chemical processes.

Why Choose S30408 vs SS 304 Steel?

| Feature | S30408 | SS 304 |

|---|---|---|

| Carbon Content | Lower (≤ 0.03%) | Higher (≤ 0.08%) |

| Corrosion Resistance | Better in welded structures | Excellent general resistance |

| Weldability | Superior, no post-weld treatment needed | Good, may need post-weld treatment |

| High-Temperature Use | Better resistance to carbide precipitation | Standard performance |

| Cost | Slightly higher | Relatively lower |

| Applications | Ideal for critical, welded environments | General-purpose, versatile |

| Chloride Resistance | Better in chloride-rich environments | More prone to pitting |

| Mechanical Strength | Comparable, with better toughness | Standard strength |

Advantages of Austenitic Stainless Steel

| Feature | Advantage |

|---|---|

| Corrosion Resistance | Excellent in various environments |

| Temperature Stability | Performs well in high and low temperatures |

| Formability | Highly formable for diverse applications |

| Weldability | High, especially in low-carbon grades |

| Non-Magnetic | Ideal for non-magnetic applications |

| Durability | Long-lasting and wear-resistant |

| Hygiene | Easy to clean, suitable for food/medical |

| Aesthetic Appeal | Attractive finish for architectural use |

| Strength | High tensile and mechanical strength |

| Environmental Impact | Recyclable and eco-friendly material |

Benefits of Ease of Fabrication

As noted, austenitic stainless steel S30408 possesses exceptional ease of fabrication, resulting in its ease of use across many industries. Its properties list contains five notable benefits of fabrication:

- Best-in-Class Weldability

S30408 stainless steel offers a true competitive advantage because of its weldability. It can be welded using various techniques, including TIG, MIG, and spot welding, without worrying about strength or corrosion resistance.

- High Formability

Despite having complex designs and shapes, this material can be bent, deep drawn, or roll formed without cracking or losing its structural integrity, unlike others. The S30408 stainless steel performs exceptionally well.

- Machinability

The other piece of good news is that S30408 possesses good machinability, which greatly reduces production time and costs. With the right tools and conditions, it can be cut, drilled, or finished to exact specifications very easily.

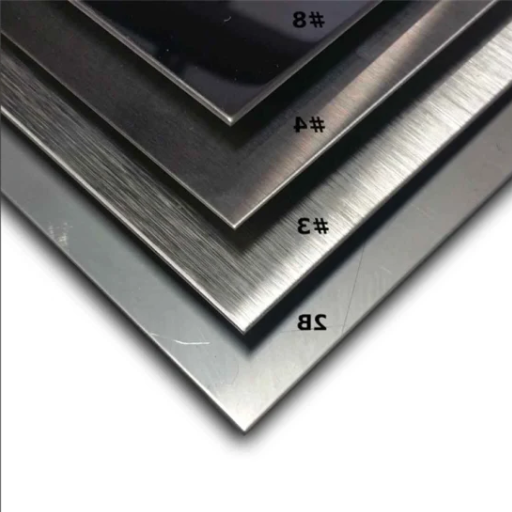

- Different surface finishing options

Austenitic stainless steel surfaces can be enhanced with various finishes, from mirror polished to brushed, meeting aesthetic and functional purposes.

- High production consistency

With the S30408 stainless steel, manufacturers gain very few production defects and consistency in their production since the steel’s behavior is predictable during the production phases.

Considerations for Chromium and Nickel Content

The chromium and nickel content in S30408 stainless steel plays a pivotal role in determining the material’s corrosion resistance, strength, and overall performance. A component, chromium, mostly eternally in the range of 18%-20%, is essential to steel for oxidation and rust purposes. On the other hand, nickel, mainly 8%-10.5%, aids in the weldability, ductility, and mildly acidic, chloride-rich environments.

Recent progress emphasizes the need to maintain specific ratios of these two components. For instance, some studies suggest that increasing the chromium content over twenty percent increases oxidation resistance at elevated temperatures but might also make the steel less weldable. Conversely, higher values of nickel are said to improve sub-zero temperature toughness, making these alloys suitable for cryogenic applications. Excessive amounts of nickel may increase costs since it is an expensive alloying element.

Maintaining a ratio between chromium and nickel is vital in manufacturing processes. A study, for example, claims that a specific ratio of chromium and nickel enhances the formability of materials and inhibits the development of specific brittle structures during the cooling process. At the same time, other industries might demand alloys specifically designed for use in chemical processing or marine environments. Thus, controlling these precise values while conforming to ASTM A240 standards allows for optimizing the alloy. This underscores the importance of understanding the composition of nickel and chrome attributes for effective S30408 stainless steel design.

References

- SteelPro Group: S30408 vs 304 Stainless Steel – A detailed comparison of the two grades, focusing on composition and standards.

- Sino Stainless Steel: S30408 vs SS 304 Steel – Discusses differences in carbon content and other properties.

- Artizono: S30408 Vs 304 Stainless Steel – Highlights the lower carbon content in S30408 and its implications.

Frequently Asked Questions (FAQ)

Q: What are the primary differences between S30408 and 304 stainless steel?

A: The primary differences between S30408 and 304 stainless steel lie in their chemical compositions and mechanical properties. S30408 is a variant of the widely used Type 304 stainless steel, with adjustments that enhance specific attributes such as weldability and tensile strength. S30408 steel is notably used in applications requiring excellent corrosion resistance and higher temperature stability.

Q: How does the composition of S30408 differ from standard 304 stainless steel?

A: The composition of S30408 stainless steel includes a slightly different balance of elements compared to standard 304 stainless steel, which enhances its weldability and mechanical properties. However, both types maintain the essential characteristics of the stainless steel family, such as excellent corrosion resistance and versatility.

Q: What are the benefits of using S30408 steel over 304H stainless steel?

A: S30408 steel offers advantages over 304H stainless steel in terms of weldability and formability. While 304H has higher carbon content for improved high-temperature strength, S30408 is preferred for environments where welding and forming are critical due to its balanced composition that minimizes the risk of cracking.

Q: Can S30408 and SS 304 stainless steel be used interchangeably in all applications?

A: While S30408 and SS 304 stainless steel share many similarities, they are not always interchangeable. The choice between these alloys should be based on specific application requirements, such as temperature conditions, the need for weldability, and corrosion resistance. It’s essential to consider the properties of S30408 and SS 304 to ensure optimal performance.

Q: How does S30408 stainless steel perform in terms of corrosion resistance?

A: S30408 stainless steel offers excellent corrosion resistance, similar to other types in the stainless steel family. It is highly resistant to pitting and crevice corrosion, making it suitable for a wide range of environments, including chemical processing and marine applications.

Q: What applications are best suited for S30408 stainless steel?

A: S30408 stainless steel is widely used in applications that require high weldability, excellent corrosion resistance, and good tensile strength. It is ideal for manufacturing stainless steel plates, sheets, tubing, and coils, where durability and performance are critical, such as in chemical processing, food processing, and architectural applications.

Q: How does the tensile strength of S30408 compare to 304L stainless steel?

A: S30408 stainless steel generally offers higher tensile strength compared to 304L, which is the low carbon version of the 304 alloy. This makes S30408 a better choice for applications requiring higher mechanical strength while still maintaining good corrosion resistance and weldability.

Q: Are there any specific welding considerations for S30408 stainless steel?

A: Yes, when welding S30408 stainless steel, it is important to maintain proper heat input and cooling rates to prevent issues such as grain boundary sensitization. The alloy’s composition allows for good weldability, but using appropriate welding techniques and filler materials is crucial to maintain the integrity and performance of the welded joints.

Q: What distinguishes S30408 stainless steel tubing from carbon steel tubing?

A: S30408 stainless steel tubing is distinguished from carbon steel tubing by its superior corrosion resistance, ability to withstand higher temperatures, and aesthetic appearance. While carbon steel is stronger and less expensive, S30408 is preferred in environments where exposure to moisture and corrosive substances is a concern.