One of the strengths of stainless steel is its long life and longstanding use, no matter the physical conditions. It is what makes the material a favorite, even in some of the most extreme conditions. Instances include but are not limited to use cases of stainless round bar in construction work, food processing and manufacturing factories, the making of various kinds of vehicles or even operations at sea. Still, there are various types of stainless steel, and 304 and 316 are the most preferred grades, for they tend to score high in aspects such as effectiveness and functionality, among others, which explains the rising uptake. Particularly, in this article, we will be discussing these types of stainless steel in detail, focusing on their advantages and applications, and how to choose the right one. Depending on the application intended for a certain material, whether it is resistant or strong, it is equally imperative to appreciate the difference between 304-grade and 316-grade stainless steel, and that is what shall follow up.

Types of Stainless Round Bars

Overview of 304 Stainless Steel Round Bar

There is a broad class of solid flat stainless steel bars available, and largely speaking, out of all the most common is 304 grade steel. It is otherwise known as 304 stainless steel, and it is an iron-based alloy containing approximately 18 – 20% chromium content and 8 – 10.5% nickel content. For this purpose, this stainless round bar form type is applicable especially in wet, chemical, and even aggressive environments. This kind is classed within the subset of austenitic stainless steels, which is non – magnetic however, it has very useful properties for structuring and welding.

Among the many advantages that are associated with the 304 stainless round bar, its endurance is one of the main reasons because it is capable of withstanding the temperatures of up to 870°C (1598°F) without losing the fibrous integrity. The activities, such as construction, kitchenware, chemical tanks, and marine-grade components, are therefore achieved with these examples. Additionally, steel reinforcement of these 304 stainless round bars is about 505 MPa or 73200 psi, while the stress level is around 215 MPa or 31200 psi, which allows for the application of the bars even in intense pressure exercises.

With regard to machinability, stainless round bar 304 is acceptable, although sometimes particular cutting equipment has to be deployed due to the high hardness of this material. Furthermore, although these bars are useful, the composition of both metals and non-metals makes this product very clean to the environment. On these grounds, a 304 stainless steel round bar is preferred in the industries that require strength, corrosion, and cost-efficient solutions, as they provide better efficiency in these areas.

Characteristics of 316 Stainless Steel Round Bar

Molybdenum contained in the 316 stainless round bar makes it more scratch-resistant than 304 stainless steel. More importantly, unlike many other steels, it is one of the few that contains potent molybdenum as an addition, which is highly useful for the prevention of corrosion, especially in foodstuffs, salt solutions containing free chlorides or acids, or in chemical processing areas, and makes the 316 stainless round bar unique. It is resistant to corrosion and even better handles pitting as well as crevice attack.

The conditions of the 316-grade stainless steel round reinforcement bar regarding the ultimate and yield strengths range from a minimum of 579 MPa and 290 up to 300 MPa, respectively, depending on how the material has been manufactured and its chemical content. The melting temperature of this material is in the range of 1370 °C (2500 °F), and this causes no problem in heat absorption. The steel, in its annealed form, is highly machinable; hence, in heavy-duty cutting applications and tools, it turns out to have hard material.

This special feature in stainless range fabrication also covers thirteen percent of reinforcement stainless round bar. Moreover, most practices are carried out using stainless steel in the medical, aviation, and construction fields. Whilst the 316 stainless steel round bar is known not to corrode under normal conditions, it also does not embrittle in the disposal process of low temperatures, as it is rather resistant to fierce conditions.

Comparative Analysis: 303 vs 304 Stainless Steel

The 303 grade steel is a variant of the stainless steel family of alloys specifically designed to enhance its machinability. The additional sulfur content increases the ease of machining this grade of stainless, especially compared to 304, though at a slight cost to its corrosion resistance. The sulfur incorporation in the alloy achieves this by enabling high-speed machining without much tool wear, which is best in applications requiring parts that will undergo a lot of machining, like screws, nuts, and bolts. This, however, comes along with certain disadvantages such as limited weldability and a compromise on the acids and chlorides resistance.

On the opposite side of the table, 304 as a grade of stainless steel material has advanced corrosion resistance, and with strength and flexibility. With its low carbon and the combination of chromium and nickel in balanced proportions, 304 works well in different fields such as kitchen appliances, equipment used in handling chemicals, and vehicles. Contrary to 303, the weldability of the 304 stainless alloys is better, and yet it can be easily fabricated, or rather pulled into different shapes without the fear of fractures.

Key Performance Indicators:

- Corrosion Resistance: 303 stainless round bar and 304 both have satisfactory corrosion resistance, but the 303 steel has a higher sulphur content as compared to the 304 steel, and this makes the 304 stronger than the 303. 304 stainless steel type is suited for use in conditions where they will be exposed to high humidity and prone to water, salts, and acids.

- Machining: For manufacturing, 303 stainless steel round bar is ideal because it allows for manufacturing at high speed, as opposed to conventional machining of 304.

- Typical analysis (estimated):

-

- 303: 17-19% of chromium, 8-10% of nickel, with 0.15% carbon and sulfur not more than 0.15%.

- 304: 18-20%. Chromium, 8-12% nickel, and carbon not exceeding 0.08%.

- Applications:

- 303 is appropriate for use in difficult machine works and parts instances, such as fittings and gears.

- 304 accommodates applications where the need for weldability as well as good corrosion resistance is present, like in food containers and some structures.

There are two grades of stainless round bar- 303 and 304. The preference for one over another is largely dependent on the characteristics required for a given application. If the considerations are mostly around the effectiveness before machining operations, one should orient oneself to 303. Alternatively, if the conditions are more of higher resistance to corrosion and better adaptability, the appropriate grade is 304.

Applications and Industries

Common Applications of Stainless Round Bar

The stainless round bar, a relatively simple form for construction, is used in numerous industries for its superior strength, durable performance throughout the seasons, and tolerance to corrosion. Here are some of the most important applications that are discussed below.

- Aerospace: The production of air vehicles employs stainless round bar in different parts such as fasteners, nuts and bolts, wheels, engine parts, and many others, owing to the tough nature of the bars and the ability to withstand extreme temperatures. As an example, 17-4PH or 15-5PH are two grades that are widely used in the fabrication of aerospace components.

- Infrastructure: Construction supports, in its basic terms, would require these bars for two complex structures, like buildings and bridges. Reinforced structures can utilize these bars as they are known to perform satisfactorily under harsh conditions, for instance, when temperatures or moisture levels exceed the permissible range. It is projected that on an annual basis within the next decades, there will be about a five percent increase in her consumption of stainless steel specifically dedicated to construction due to global urbanization.

- Motor Vehicles: Including but not limited to suspension parts, axles, driver’s chambers, etc., stainless round bars are also used for fabrication. High-quality stainless steel is used mostly in this kind of “electro-eco” transport.

- Food and Beverage Industry: Due to its utility in medical equipment, storage, and corrosion resistance, stainless round bar is mandatory when designing items such as food mixers, tanks, processing pipes, etc. For the purpose of designing these machines, grades like 304 and 316 are extensively applied, which are also compatible for food-grade FDA purposes.

- Oil and Gas Sector: Without any doubt, stainless round bar holds its importance in the production of various components such as valves, fittings, and pipelines used both onshore and offshore. They all are all corrosion-free devices which can withstand the extreme environments of high temperatures and chemicals, thereby necessitating their extreme use.

- Medical Devices and Accessories: Medical spheres include some of the elements, such as surgical equipment and metal devices, including those used for joint replacements and hospital equipment. The biocompatibility and sterility offered by stainless steel are of utmost importance, particularly surgical stainless steel and the 316 variety. In 2023, the market for medical stainless steel exceeded two billion dollars, and it’s only up till now because the market is heavily reliant on such materials.

- Shipping Industry: In the maritime context, stainless round bars are applied in the construction of boats and ships and other support structures such as propeller shafts, railings, and fittings. Generally, marine applications of steel are composed or anticipated due to its strength to resist the action of seawater, as in the case of 316 and 316L.

The reports project the value of the world market for stainless steel bars at less than 10 billion up to the year 2030. Most importantly, these include the automotive and construction industries and the healthcare sectors. All these uses would demonstrate how useful and all-purpose the stainless round bar is in the 21st century.

Industries Utilizing 304 and 316 Stainless Steel

The engineering materials of stainless steel grade series 304 and 316 are significant in the industries for a number of reasons such as availability, cost-effectiveness, strength properties, and resistance to corrosive agents. The demand for 304 stainless steel is high because it is a strong material that is suitable for many applications including building construction both onshore and in the underground, however, the price of cold rolled 304 steel is cheap whilst 316 series is a more expensive option due to effective resistance against aggressive substances or solutions commonly containing large amounts of chlorides thanks to inclusion of molybdenum. This is depicted in the sectors:

- Building construction: As a result, they are excellent building materials that are fitted with 304 stainless steel as well as 316 Stainless steel for their essential durability, cosmetic reasons, and weather proofing. Functionally, these products are primarily applicable in areas such as decks and roofs, structural exteriors, or contain surfaces of the structure. According to the reviews, in 2022, stainless steel in the construction industry comprises approximately 20% globally. There can be no mistaken, therefore, that industries have embraced the use of steel in constructing eco-structures pointing to the importance of this resource.

- Food & Beverage Segment: 304 and 316 grades of stainless steel do not interact with food, thus forming tanks, vessels, and other equipment as well as kitchenware for food and food-related industries. Particularly, Grade 316 is corrosion-resistant and can therefore be used in most acidic and saline food containers. The growing trend of packaged and ready-to-eat foods has led to the excessive demand for stainless steel due to the expansion of food processing.

- Healthcare and Pharmaceutical Sectors: The biocompatibility of stainless steels, like 316 and other grades, and their ability to be sterilized has made them suitable for use in the manufacture of stainless products used in the healthcare and pharmaceutical industries. Such alloys are utilized in the production of medical devices that include surgical tools, implants, and other hospital appliances. Based on this report, the latter industries will account for most of the usage of stainless steel due to the expansion of the medical and pharmaceutical fields, due to better health care facilities and technologies.

- Maritime Industry: Owing to the high quality of corrosion resistance of 316 stainless steel to seawater, it is mostly used in sea service applications. Marine structures, including but not limited to vessels and platforms, require such steel owing to its corrosion-resistant characteristic. Globally, the market associated with the sea sectors, including growth known as the blue economy, is expected to expand by about $ 3 million dollars by 2030. As a result, the consumption of 316 stainless steel in this sector will also increase.

- Motor Industry: There is a growing demand for the utilisation of stainless steel grades 304 and 316 in the manufacture of exhaust systems, fuel storage tanks, and any related structure. In all the sectors, the light weight, the strength, and the ability of the material to be recycled provide the industries with the option of putting greater emphasis on energy efficiency and on measures to ensure that the industry can produce sustainably. This is expected to increase the global acceptance and adoption of hybrid or electric cars, which consume more round stainless bars.

There is a high demand for 304 and 316 stainless steel in new and rapidly expanding sectors, given its numerous advantages as a stainless steel. Due to its usefulness in various stress conditions, the use of such materials, nowadays, cannot be eliminated in any engineering or production process.

In stainless steel mass production, more specifically, stainless round bar semi-finished products without any porosity are more common.

Case Studies: Successful Use of Stainless Round Bars

- Oil and Gas Sector

The stainless round bar has been very effective in this industry owing to its resistance to corrosion and extreme heat. The 316, for example, is utilized in the construction of offshore platforms and underwater networks due to the contact with seawater and the absence of easy environments. More so, it has also been said over the years that 316 stainless steel is twenty percent more economical for repairs since it doesn’t need to be repaired, unlike the other materials that are present.

- Automotive Industry

For example, the automotive industry production runs stainless round bar, round bat includes, apart from others, the production of several important vehicle parts such as the drive shaft, axle, or engine parts. These components act as essentials for the proper functioning of the vehicle. A 2023 research study does not address how, when, and 304 stainless steel round bars were incorporated into the manufacturing of electric vehicles (EV) components, which enhanced by 15% of the component wear and tear, drop in emissions of production. This shows their importance in sustainability and division.

- Medical Instruments

In the field of health, 304 grade stainless round bar is used in various fields, including the manufacture of surgical devices, orthotic devices, bed rails, and other equipment in hospitals. No doubt, this is possible due to their high biocompatibility and ease of sanitization, which is essential in medical practice. The statistical figures from the medical production sector statistics for 2022 indicated that there was a 12% growth in the need for specific stainless steel used in medical equipment, thanks to the construction and equipping of medical institutions with new technologies.

- Construction & Architecture

Steel round bars find a wide range of applications in the building industry, among which structural supports, cladding of curtain walls, and even interior decoration are some of the largest sectors. This is due to the making of such structures in most cases in seaside constructions or city buildings, because they are durable and are not prone to rust. An instance is during the building of a skyscraper in Singapore, where stainless bars were used in construction, and it has been said that the reinforcement of the structure will last for thirty years without significant degradation, unlike when it would have been built with the usual materials.

For example, it could be mentioned that the reason behind the diversity of applications and the above benefits of those multi-purpose building materials, which especially arise from the vertical usage of stainless round bar, should be emphasized these days of modern amenities and efficient usage. Moreover, industries that can find fast expansion and respect for environmental issues give more reason to this scientific and industrial need.

Advantages of Stainless Round Bar

Corrosion Resistance: Why It Matters

There is a high demand for stainless round bar in the different industries and sectors, which include construction, automobile, and maritime industries. There are many reasons for this. One of the reasons is that this component possesses a very high strength against corrosion. Stainless steel is most resistant to corrosion when it is rich in chromium between 10.5% to 30%. This is due to the tendency of chromium to produce a thin protective oxide layer on the surface of the base alloy, thus protecting it from being oxidized further or aggressively in such environments.

For example, 304 and 316 stainless steels are two of the most common grades of stainless steel that do not rust and corrosion in contact with moisture, oxygen, and chemicals. Adding molybdenum to grade 316 enhances the resistance to various chloride solutions; the stainless steel round is more appropriate for sea installations as well as plant equipment. According to International Stainless Steel Forum research, these facts have led to the longer use of the products made from stainless steel, which saved money spent on the proponents’ replacement and decreased the threat to the environment.

Moreover, some researchers demonstrate how a stainless steel round bar remains cast in its default shape and can withstand any extremities condition. As an example, from the study on PCC, the depicted electrochemical behavior proves that stainless steel is stable and, in particular, is more effective in the acidic pH as well as the alkaline pH of the environment, a fact that many other studies also support. This renders them very dependable in the context of bearings in moisture-laden, seawater-filled or acidic chemical environment etc.

The effectiveness of the regulation of the circulation of currency depends on the efficiency of the implementer of the projects, the completion of the projects, and their effect on the environment. Better safety in the industrial realm can be achieved with a stainless round bar since it has positive attributes enhancing the wear resistance of the material, prolonging its service life, and reducing the total cost of repairs and maintenance. Generally, such strategies/skills have made the sales reduce the through cost and also the extended life span, which is that as it is now in all the industries, ranging from the chic technologies to the old art and craft reverts to the so-called sustainable development nowadays.

Strength and Durability of Stainless Round Bars

Certain uses have stainless round bar in mind since their study already articulates that they are durable and last long. More often than not, such bars are composed of a superior grade stainless steel which exhibits fine mechanical properties. For example, grades 304 and 316 stainless steel have an ultimate tensile strength of approximately 485 to over 620 MPa. This is important because these values are above the yield strength threshold, which keeps them from bending or breaking when weight or pressure is applied.

One of the most crucial factors affecting their longevity is the material, such as stainless steel. This material contains chromium, nickel, and molybdenum. In particular, chromium defines the limits of the material to strain, damage, environment, and its other properties. In addition, Nickel and molybdenum increase the strength of stainless steel, especially when temperatures and pressures increase. Another factor is that stainless round bar has a fairly high hardness capability with Brinell and Rockwell hardness values that may go beyond the stipulated industry norms.

Drawing from these attributes, stainless steel round bars examine application in construction, marine, and manufacturing activities with regard to irrepressible working conditions. The development of some structures that require minimal fatigue, such as bridge supports, for example, has incorporated them. Furthermore, the stainless round bar can be machined for mechanical purposes — both maintenance and action — tempered and coaxed to greater strength.

Versatility in Various Applications

Across all domains within the modern economy, stainless round bars perform the dual function of imparting high strength and elasticity, and therefore find numerous applications in all spheres. Speaking about some particular sectors, the engineering and automotive industries are two where such round bars find application rather often. It is, for instance, steel bars developed from stainless round bar that are used to make items like drive shafts, motor shafts, fasteners, and safety fasteners to uphold the performance of a vehicle. According to the recent statistical reports, such a pattern is expected to remain on the rise as the trend of automotive electrification and automation will be more and more emphasized.

Moreover, stainless round bar has corrosion-resistant properties, which are very useful in shipbuilding and other deep-sea installations. In addition, due to the presence of aerial contaminants in the harsh environment of the sea, the steel structures can withstand such environments for a longer period, thus helping boost production levels as the costs or maintenance bottlenecks are cut down. Worse prognostics predict that the marine applications of stainless steel will still register an increase by 5.2% annualized from this year to 2030. Incorporating the maritime policies may therefore become an inevitable activity.

An additional enterprise is to enhance construction activities. Construction of advanced poles and columns requires a variety of functional equipment; however, only a small number is made from a stainless steel round bar. The concrete walls are over stainless steel columns, which support the weight of tall buildings, such as but not limited to towers and high-level bridges. Therefore, their parts can be kept even in damp conditions and meet the test of time without concerns of corrosion, even when there is evaporated salt water. Therefore, in this case, a method will have increased the cost by around 50 per cent from simply using steel, and this has been derived from the recent engineering activities.

Many engineers deal with stainless round bars for a large number of alloys and heat treatment methods, where all are evolving constantly. This strength indicates the society embraces more of the advancement of such products, containing reliance and hope, into its spread.

Manufacturing Process of Stainless Round Bars

Overview of Production Techniques

To produce a stainless round bar, specific multiple steps are taken to obtain high performance in the final product and its durability. Factors that really matter during the production processes include:

- Melting and Casting

Stainless steel production usually takes place in an EAF or an electric arc furnace, where the iron ore and chromium-based materials are made to melt. Thereafter, the molten steel is cast into various molds, such as ingots or slabs, in the case of hot metal. Also, industrial information today, for example, says that the range of temperature for the melting process is usually around 2,500 to 2,800 degrees Fahrenheit or 1,370 to 1,54 degrees Celsius.

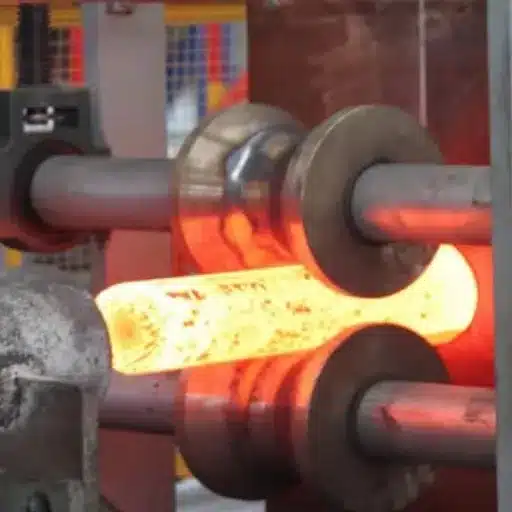

- Hot Rolling Process

Finally, the billets are heated and passed through several stands of rolling mills, which help to change the size of the billets and roll them into round bars. Numerous studies indicate that hot rolling of stainless steels is done at temperatures of 1800°F to 2000°F (980°C -1200 °C ) or more, depending on the alloy. Indicators of hot rolling of specific types of steel are temperatures.

- Heat Treating

The main and often used improving mechanisms are the heat treatment processes of annealing, hardening, and tempering, which are introduced to improve the general mechanical and materials qualities as well as corrosion resistance of the stainless round bar. As an illustration, annealing will soften the material to increase its toughness and hence reduce noise. On the other hand, quenching increases the heating capacity of steel.

- Proceedings of a cold pre-rolling

There is a probability of the undesired dimensions of a consumed stainless round bar and its finish, which makes it necessary to perform cold work on a hot stainless round bar to the desired and precise dimensions. Processes such as drawing, peeling, peeping, or lying are conducted for the purpose of working the desired application to achieve a specific goal. However, it is general knowledge that while working on cold roll-formed stainless steel bars, the yield strength is naturally increased by not more than 20% or 30% relative to the original strength.

- Polishing and Descaling

Descaling all bars, burning any poignant membrane of the oxide while obtaining a consistent layer of finish. This helps limit their weathering and accompanies them from the eventual oxidation processes that may occur.

Stainless round bar can be manufactured routinely and almost eco-friendly, utilizing maximum quality as well as state of the art monitoring systems and processes automation mechanisms through the aforementioned processes. Specialists in the industry report that today’s production lines achieve an efficacy of over 90%, thus minimizing wastage and increasing energy efficiency. This kind of technological progress is proof of why stainless steel is also the subject of various innovative manufacturing methods. For instance, it will take less time and effort to take care of XP issues translated to reducing the cost of actual pov. Secondly, the sense of the words still allows one to create several combinations.

Quality Control in Stainless Round Bar Production

Quality control is so crucial when it comes to stainless round bar manufacturing that it ensures products are frozen to perform well, last for a long time, and in most cases adhere to safety standards. Quality assurance processes today include not only traditional methods but also high technology to achieve a flawless course of action for manufacturing companies. The QC process may involve material assessments, dimension inspections, or perhaps surface audits.

In most cases, materials are tested using spectrometers and X-Ray Fluorescence (XRF) analyzers in order to verify that a certain grade of stainless steel, like 304 or 316, is in use. It is estimated that spectrometers have a precision of 98%, which is evident from papers on today’s techniques in industries. Hence, spectrometers are now an integral part of quality controls.

It is essential to ensure the conformity of the dimensions during the production of any finished billet. Today, the main parameters of round/plain bars are usually measured using a laser, which self-updates the data with its own information on the diameter, length, and run-out of the bars. Some of the devices even recognize a deficit down to as low as 0.01 mm, which helps to reduce the tolerance applicable in manufacturing certain products like aerospace and industrial machines.

In application to the surface finishing thickness is concerned with simplicity of avoiding features such as scratching or dents. The latest polishing devices and some non-destructive testing (NDT) procedures, such as ultrasound or magnetic inspection, among others, are used so as to meet the desired surface finish characteristics. Available statistics indicate that plants that employ the advanced NDT techniques have an over 90% success rate of indicating defects in the products.

Even in a stainless round bar, there is a need to measure statistics such as lengths and roundness during production operations to maintain the consistency of the process.

The inclusion of these advanced quality management techniques means that producers not only comply with global standards and principles like ISO 9001 but also enhance customer satisfaction and product reliability. This blend of innovations and strict quality standards is a welcome uptick in the stainless round bar industry.

Factors Affecting the Manufacturing Process

A number of factors have a strong effect on the production efficiency, cost and environmental sustainability of the stainless round bar manufacturing process. These factors include, but are not limited to:

- Quality of Initial Raw Materials

The end product is greatly affected by the raw materials because poor-quality raw materials will give poor quality end product. Various elements such as iron, chromium, nickel, and others form stainless steel. For example, to guarantee corrosion resistance, high chromium content is used, increase in nickel content results to tensile strength. Recent reports in the global market have shown that there is an increasing requirement for high-quality stainless steel that has led to strict measures of raw materials so as to adhere to desired qualities.

- Evolution of Technology

In present times, the practices of manufacturing incorporate using at least one of these technologies – automated CNC machines, precision furnaces – both of which enhance and unify bar dimensions as well as the texture on the surface of such bars. Information received in some recent publications states that production efficiency for manufacturers adopting Industry 4 0 enabled practices, including AI in process optimization, has increased by 25 percent and a reduction in fall in material consumption.

- Temperature Control

One of the most cardinal things while performing manufacturing for melting, casting, or heat treatment is the temperature. Inappropriate variation in temperature affects distortion, and mechanical properties of bars in extreme cases. Studies indicate that deploying constant temperature supervision cuts product defects by up to 18 percent.

- NDT Techniques

Examinations are done on the surfaces of finished parts to determine whether or not NDT is useful when it comes to more complex designs. Techniques of measurement used in mechanical processing sometimes employ sher, wires or in some cases lead ingots, due to which the Stainless Round Bar may have misalignments due to forces applied during deformation. Therefore, it becomes necessary to carry out nondestructive testing before beginning any production to prevent loss of time. However, comparatively few defects can be avoided using this approach.

Include Non-Destructive Testing (NDT) as it remains an integral factor in the stainless round bar production industry. NDT comprehensive techniques such as ultrasonic tests, eddy current, and radioactive testing leave no room for the presence of any defects in the products. The existing developments show an increase in NDT usage worldwide since 2020 by 15 %, promoting a high-quality process throughout the manufacturing stages.

- Sustainability Measures

The shed light on increasing regulations has witnessed the adoption of environmentally friendly systems in most industries. Manufacturing industries are increasingly adopting energy-efficient production processes to cut down on carbon emissions. The International Energy Agency (IEA) report shows that carbon dioxide emissions can be reduced by approximately 30 percent in any production system without affecting the output when renewable sources of energy are incorporated.

Concerning all these aspects and intelligent tools, the stainless round bar sector still focuses on effectiveness, strength, and customer support as its main more significant cores.

Maintenance Tips for Stainless Round Bars

Best Practices for Care and Maintenance

One of the most crucial aspects of ensuring that stainless bars serve their intended purpose effectively is in their proper maintenance and storage. Below are some recommendations for the users, under the present circumstances, which incorporate the recent developments in the business segment:

- Cleaning regularly: As the name suggests, stainless steel round bar is immaculately clean because it is not allowed to get soiled, grimy, and rusted. Such is the case, and in particular, concerning cleaning, a soft wet cloth or a foam with a mild soapy water is recommended. Do not attempt to use any rough materials, as this may cause serious structural issues, and such issues are bound to worsen as time goes by. There is new research conducted which promises that if it is cleaned regularly, then the build quality of such steel-based parts increases by 30%.

- Do Not Let the Bars Mingle with Salt: stainless steel is very tough, but it has a huge weakness – salt, or any other chlorides. If you live near a waterfront, or if you drive on salt-treated roads, make it a habit to thoroughly rinse the bars with fresh water. The results of one study tested in 2021 suggest that in the case of chlorides, if stainless steel is not adequately rinsed, the susceptibility of the material to break increases by 25% compared to a benchmark level.

- Investment in Surface Protective Measures: The application of any paint or finish is already protective in and of itself. In industry, novel corrosion barriers such as anti-rust pigments or sealants are advised. There is a respectable amount of literature that indicates that coatings can reduce the incidence of corrosion by over 40 percent, especially in environments with high levels of humidity.

- Perform Regular Inspections: Check for any obvious signs of mechanical wear and tear, rust or even more serious impacts such as deformations, breakages etc. Any issues found at this stage will help to save on the substantial costs of repair or replacement. Presently, the inspection methodology uses state-of-the-art technologies like ultrasound that permits to perform manufacturing inspection and visual-checks of internal defects with up to 95 percent accuracy.

- Properly Provision for items: Make sure that the stainless round bar is kept near dry, clean, well-ventilated, and excess height should be avoided. Always make sure that protective measures, such as soft coverings or even non-metal obstacles, are engaged during storage arrangements. According to some industry data, as much as 20% of equipment wear caused by use can be minimized simply through proper equipment storage.

- Bond with the Manufacturer Guide: In case of manufacturer care guidelines, make sure you bond with the manufacturer’s guidelines, which will offer care for the different types of stainless steel, because most require different treatment. For instance, 316 stainless steel will demand more finishing than the commonly used 304 stainless steel due to its corrosion resistance.

By obeying the following ways, people and companies are prone to the utility of stainless round bar for several operations quite effectively and optimally for years, on the assumption that they do.

Preventative Measures Against Corrosion

When it comes to stainless round bar, however, it is well known that the efficiency of corrosion tackling is extremely conditional on how you look after the component and the environment as well.

However, recent investigations demonstrate that an increase in the local concentration of chlorides, e.g., in the coastal areas or in the industrial areas speed up the corrosion processes remarkably. Therefore, in such instances, stainless steel variations have to be produced, e.g., grade 316 with higher molybdenum additions in the applied composition. The molybdenum content of 316 reaches 6% when there is actually no molybdenum in 304, allowing an increase in pitting resistance index (PRE).

Quantitative analysis exemplified the importance of common devices such as cleaning and conditioning. It is the practice not to use any detergent during scrubbing but rather to rinse with plain water, which helps in sustaining the existing oxide layer on the stainless steel surface. As per details from NACE International, the clean and maintained apparatus that resides in the controlled atmosphere shows service time expansion by one quarter as opposed to the declining components.

Aside from protective coatings, different sectors use cathodic protection methods when designing structures prone to severe corrosive environments. Electropolishing, on the other hand, is a new technique that simply removes the visible scale while improving the corrosion resistance properties. When all these measures are taken, and the appropriate type of stainless steel is used, there is no reason why firms should not be able to preserve the integrity and usability of the stainless round bar even in the most arduous conditions.

When to Request a Quote for Replacement

There is a tricky task that requires great attention, and that is when and the way to initiate the process of requesting a quote for the replacement of stainless round bar. To this end, it is very crucial to note those old and frequent problems, such as wear on the bars leading to picture pitting, cracking or even rust, as they are considered ancient history because every measure has been put in place to eliminate such occurrences, thus assuring there will be no halting in activities. Working life, in most cases, is dependent on the consumption of a given stainless steel subtype. For instance, 316 kinds of stainless steel are typically used for corrosive surfaces that are expected to come into contact with salts, such as occurs in many marine facilities, due to their better resistance to rust when compared to 304 steels.

Current business data hints that sticking to modern preventive maintenance strategies, as well as regular inspection, could possibly increase the lifespan of some stainless steel round bar structures. Ten to eleven years; corrosion test results suggest such structures should be between, call it 10–15 years or 15–20 years, and this is without the body collapsing. This, however, is influenced by the conditions of the work site, such as dampness, chemical, and physical action. Available are instruments such as protracted duration anticorrosion instruments or advice from specialists, which will assist in comprehending the problem earlier on, that is, cost and time, and working time is saved.

When the cost of repair exceeds the cost of replacement or when workloads naturally skyrocket, requesting an additional budget would be ideal. It may be a challenge sourcing for stainless round bar in some instances; however, proper suppliers coupled with the latest trends in terms of materials and costs will ensure optimum outcomes in the supply of good quality worked material in the least possible time.

Reference Sources

- The sustainability of the mechanical generation of feedstock from 316L stainless steel.

The research project will look at how feasible it is to machineries mechanically generated feedstock utilizing 316L stainless steel bar stock and evaluate the application of the materials in question.

View the study here - A Review of the Stainless Steel 21-6-9 Alloy

The article reviews the technical specifications, properties, and uses of stainless steel, whereby certain specimens have been considered as case studies to give an idea of likely (practical) use in the plant.

Read the full review here - Forecasting for the Stainless Steel Round Bar Industry in 2032

This report lays emphasis on the study of stainless steel round bar markets, especially evaluating production and growth trends therein, to prove its practicality in several projects.

Check the report here

Frequently Asked Questions (FAQs)

How does the availability of round bars affect lead times?

We ensure that we have a stock of round bars, including the 304 stainless round bar, for the purposes of minimizing lead time for quite a number of orders. Different types of stainless steels and aluminum are also available in stock to ensure clients can choose the best application. When fulfilling an order, if the required dimensions are already in the rod stock, one can either send over the lengths that are as such on site, or one can request that the lengths to be cut to specific lengths. It may also be necessary to source specially made materials for tailored sizes and custom chemical compositions. This data should be sent to us shortly. Do you wish for a quotation? Then some grinding machines are provided, and such work will be possible.

What are the Options for Stainless Steel Grades and Round Bar Material Composition?

We provide several grades of stainless steel, ranging from the very common ones to some rare quality special stainless steels that have to meet certain chemical and physical requirements. Most of the grades under consideration have their own specific ASTM codes and are meant to be used for components operating under atmospheric conditions and at higher temperatures. The majority of our documents support the application of each of the grades to certain uses, more so regarding their tensile, yield strength, and corrosive chemical behavior. Test reports in the form of mill reports are available in case customers find it hard to believe a grade is something that is easy to work with or that is excessively anti-corrosion. Highly specialized grades are usually ordered or made on request only. Kindly contact us to check the possibility of manufacturing and its lead time.

Is it possible to have stainless steel round bar stock cut to a specific length?

Yes, we can cut or provide custom-cut rod and round bar stock so that they can be inserted with dimensions as required without any difficulty. Such processes involve grinding, basic cutting, precision cutting operations like machining, as well as many more, to produce high-tolerance parts in the form of machine parts and other similar industrial applications. In any case, the customer should not purchase available length or diameter if it won’t be possible to conform to the required sizes in any other way. Finishing services to assist with surface characteristics may also be offered on demand, such as for non-magnetic or polished surfaces. Custom lengths, tolerances, and secondary operations available by request.

Is a stainless round bar appropriate in rugged ambient conditions, considering its use in the presence of chemicals?

There are different stainless round bar grades that offer temperature and weathering resistance, including protection against most caustic agents in a very harsh environment. The only difference is the chemicals present, temperature levels, and operating pressures when devices are used – this is what determines which grade of stainless tubes has to be chosen. We even have alloys provided to us, for instance, high-heat or highly corrosive applications, finishing test requirement and provision of samples. From a design standpoint, formability and welding properties are also taken into consideration when choosing a grade. If you areore a taking a certain risk in making a material selection, we can help you out with reference details.

What are the differences between rods and round bars in terms of tensile, weldability, and other mechanical properties?

The tensile, yield, and mechanical properties, such as weldability, are different between the various grades, and the influence of the chemistry and heat treatment of stainless bars on the grade varies. SS with low carbon can be welded with less difficulty and with quality; there is no loss of surface resilience to corrosion. In the end, stainless steel alloys with high strength are utilized for structures requiring very high tensile strength. Tolerances in dimensions, including the measure achieved in the surface grinding and polishing, are also important for purposes of fitting and use in devices. We supply specifications and mill reports, which will help in assessing the feasibility of welding/fabrication and forming processes. Depending on machinery or industry needs, the optimal grade and a precise quotation will be provided by our experts.

How do I purchase stainless round bar, request a quotation, or receive a custom solution?

You can easily place an order, as all you need to do is select the material and the required size from the online metals’ catalogue or avail of custom options and specialized specifications through a phone call. When it comes to in-stock items, we are known for having a large stock range and working to custom dimensions and tolerances for most items. If the project requires a custom solution, we also provide services of special cutting, grinding, and finishing, and will gladly help in the choice of a supplier and grade suitable for various sectors. Please do go ahead and request a quotation and state the length, diameter, grade, and any machinery operations if necessary. We will get back to you in a short time with the relevant prices and lead times, along with the means of delivery.