Get in touch with us

Leave a message

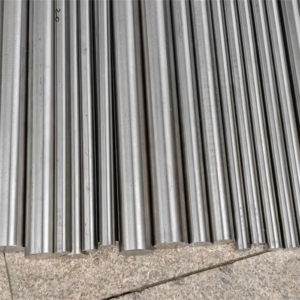

Discover our premium stainless steel bar range, engineered for durability and precision. From versatile round and flat bars to specialized hexagonal and threaded rods, our SS bar stock meets diverse industrial requirements. Available in various grades and sizes, our stainless steel rods deliver exceptional corrosion resistance and structural integrity for your most demanding applications. Trust our expertise for quality SS bar solutions that stand the test of time.

Stainless Steel Bar and Stainless Steel Rod are governed by standards like ASTM A276, A479, A582, and A484, ensuring consistency in quality and performance. These specs cover hot-rolled, cold-drawn, and forged products, with grades such as 303, 304, 316, and 410 defining their properties. For example, ASTM A276 applies to stainless steel round bar and ss bar stock, while A479 includes pressure vessel-grade Stainless Steel Bar. Classifications include austenitic (e.g., 304, 316), ferritic (e.g., 430), and martensitic (e.g., 410), each suited to specific environments and stresses.

Stainless Steel Bar and Stainless Steel Rod come in a variety of sizes to match project needs:

This range ensures Stainless Steel Bar fits both small-scale repairs and large structural builds.

Stainless Steel Bar and Stainless Steel Rod are available in multiple forms and finishes:

These variations allow Stainless Steel Bar to balance functionality and appearance.

| Grade | Characteristics | Applications |

|---|---|---|

| 303 | High machinability, good corrosion resistance, non-magnetic | Fasteners, fittings, shafts, automotive components |

| 304 | Excellent corrosion resistance, weldable, formable | Food processing equipment (e.g., tanks), architectural railings, kitchenware |

| 316 | Superior corrosion resistance (chloride environments) | Marine fittings, chemical containers, surgical tools, coastal structures |

| 410 | High strength, hardness (heat-treated), magnetic | Cutlery, turbine blades, valves, pump parts |

| 430 | Good corrosion resistance, magnetic, cost-effective | Appliance trim (e.g., refrigerators), automotive exhausts, decorative panels |

A:A stainless steel bar is a solid, elongated piece of stainless steel, typically in grades like 304 or 316, available in shapes like round, square, or hexagonal. It’s used in construction, machining, and manufacturing.

A:For corrosion resistance, 316 stainless steel bar is better in marine or chemical settings due to molybdenum. 304 is more cost-effective for general applications with less harsh conditions.

A:Yes, stainless steel bars can be bent, especially in the annealed condition, using heat (around 800°C) for thicker bars or cold bending for thinner ones, though they may work-harden during the process.

A:Stainless steel bars come in three main types: round bars for machining, square bars for structural use, and hexagonal bars for fittings and fasteners, each suited to specific applications.

A:Steel refers to the material—an iron-carbon alloy—while a bar is a specific form of steel, like a stainless steel bar, which is a solid, elongated shape used for structural or machining purposes.

A:Stainless steel bars resist rust due to their chromium content, but 304 may rust in saltwater, whereas 316 is more resistant. Proper maintenance ensures longevity in corrosive environments.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.