Get in touch with us

Leave a message

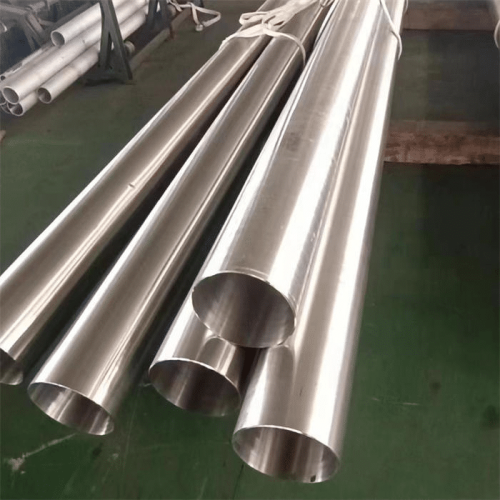

Our 310S Stainless Steel Rod is available in versatile specs:

Looking for specific 310S stainless steel rod sizes? We’ll tailor it to your project.

The 310S Stainless Steel Rod shines in these industries:

From 310S stainless steel flat bar to 310S stainless steel bar stock, it’s endlessly adaptable.

| Element | Percentage (%) |

|---|---|

| Chromium (Cr) | 24.0–26.0 |

| Nickel (Ni) | 19.0–22.0 |

| Carbon (C) | ≤ 0.08 |

| Manganese (Mn) | ≤ 2.0 |

| Silicon (Si) | ≤ 1.5 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.03 |

| Iron (Fe) | Balance |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 515 MPa (75 ksi) |

| Yield Strength (0.2%) | ≥ 205 MPa (30 ksi) |

| Elongation | ≥ 40% (in 50mm) |

| Hardness (Rockwell B) | ≤ 95 |

The 310S Stainless Steel Rod handles chemicals like a pro:

It’s a solid choice for SS 310S bar in high-heat, dry conditions.

While 310S Stainless Steel Rod is exceptional, note these constraints:

Plan your 310S stainless steel threaded rod use with care.

| Environment | Resistance Level |

|---|---|

| Atmospheric (Dry) | Excellent |

| Oxidizing (High Temp) | Very Good (up to 2000°F) |

| Nitric Acid (Dilute) | Good |

| Wet Chloride Solutions | Poor (risk of pitting) |

| Carburizing Atmospheres | Moderate |

Contact us for detailed corrosion resistance data specific to your application.

Optimize 310S Stainless Steel Rod with these techniques:

These tips ensure top-notch 310S stainless steel flat bar results.

Tom H.

Furnace Technician

Emily S.

Petrochemical Engineer

Raj P.

Food Equipment Supplier

A: 310S has lower carbon (≤ 0.08% vs. ≤ 0.25%), improving weldability and reducing sensitization.

A: Depends on size and finish—contact us for a precise 310S stainless steel rods quote!

A: Not ideal; it’s better suited for dry, high-temperature conditions.

A: Yes, its low carbon content makes welding a breeze with standard methods.

A: Up to 2000°F in continuous service, 1900°F for intermittent use.

A: Absolutely—specify your needs, and we’ll deliver!

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.