Get in touch with us

Leave a message

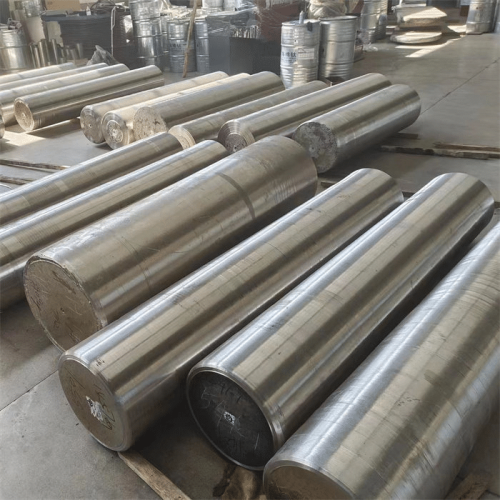

Our 316 stainless steel Bar sizes are customizable to suit your project:

Looking for specific 316 stainless steel rods? Our factory can deliver tailored solutions!

The 316 Stainless Steel Bar is widely used across industries:

From 316 stainless steel round bar in marine hardware to ss 316 bar in chemical plants, its uses are vast.

| Element | Percentage (%) |

|---|---|

| Carbon (C) | ≤ 0.08 |

| Chromium (Cr) | 16.0–18.0 |

| Nickel (Ni) | 10.0–14.0 |

| Molybdenum (Mo) | 2.0–3.0 |

| Manganese (Mn) | ≤ 2.0 |

| Silicon (Si) | ≤ 1.0 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.03 |

| Iron (Fe) | Balance |

| Property | Value |

|---|---|

| Tensile Strength | 515–690 MPa |

| Yield Strength (0.2%) | ≥ 205 MPa |

| Elongation | ≥ 40% |

| Hardness (Brinell) | ≤ 217 HB |

| Density | 8.0 g/cm3 |

Despite its strengths, the 316 Stainless Steel Bar has limits:

Consult our team for alternatives in extreme scenarios.

| Environment | Corrosion Resistance | Notes |

|---|---|---|

| Atmospheric (Urban/Coastal) | Excellent | Resists rust in humid and salty air. |

| Saltwater (Marine) | Excellent | Superior resistance to pitting and chlorides. |

| Mild Acids (e.g., Sulfuric) | Good | Handles dilute acids well; test for strong acids. |

| Alkaline Solutions | Excellent | Strong resistance to bases like sodium hydroxide. |

| Industrial Chemicals | Good to Excellent | Depends on concentration; ideal for mild solvents. |

Contact us for detailed corrosion resistance data specific to your application.

Welding the 316 Stainless Steel Rod is efficient with:

Tips:

For 316 stainless steel threaded rod or custom shapes, our manufacturer offers pre-fabricated options.

The 316 stainless steel rods we ordered for our pharmaceutical equipment were spot-on. Exceptional quality and quick turnaround from a reliable distributor. Will order again!

Michael T.

Quality Control Specialist

We purchased 316 stainless steel flat bar for a coastal construction project. The material held up perfectly against saltwater exposure, and the service from this manufacturer was outstanding!

Rachel S.

Project Manager

Lisa P.

Plant Engineer

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.