Get in touch with us

Leave a message

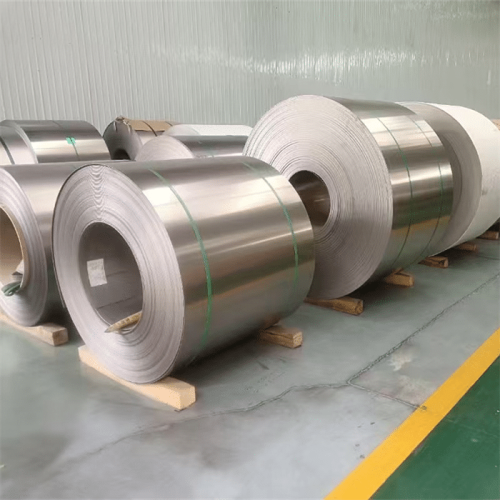

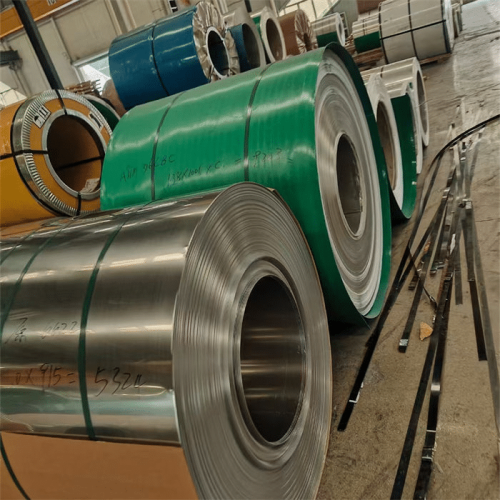

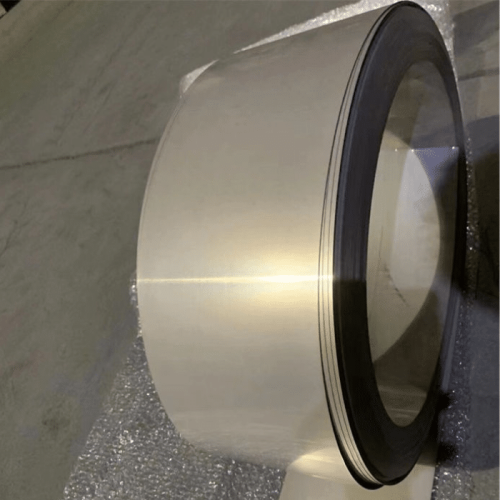

Are you wondering about the price of 316 Stainless Steel coils? Costs vary based on thickness, width, and order size. Contact us for a tailored quote. As a premier manufacturer and distributor, we provide top-grade 316 stainless steel coil stock at unbeatable rates.

Need specific dimensions? Our factory offers customization for your project!

| Element | Percentage (%) |

|---|---|

| Carbon (C) | ≤ 0.08 |

| Chromium (Cr) | 16.0–18.0 |

| Nickel (Ni) | 10.0–14.0 |

| Molybdenum (Mo) | 2.0–3.0 |

| Manganese (Mn) | ≤ 2.0 |

| Silicon (Si) | ≤ 1.0 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.03 |

| Iron (Fe) | Balance |

| Property | Value |

|---|---|

| Tensile Strength | 515–690 MPa |

| Yield Strength (0.2%) | ≥ 205 MPa |

| Elongation | ≥ 40% |

| Hardness (Brinell) | ≤ 217 HB |

| Density | 8.0 g/cm3 |

Our team can guide you to alternatives if needed.

| Environment | Corrosion Resistance | Notes |

|---|---|---|

| Atmospheric (Urban/Coastal) | Excellent | Resists rust in humid, salty, and polluted air. |

| Saltwater (Marine) | Excellent | Superior resistance to pitting and crevice corrosion. |

| Mild Acids (e.g., Sulfuric) | Good | Effective against dilute acids; test for concentrated solutions. |

| Alkaline Solutions | Excellent | Strong performance against bases like sodium hydroxide. |

| Industrial Solvents | Good to Excellent | Handles mild chemicals well; depends on exposure duration. |

Contact us for detailed corrosion resistance data specific to your application.

Welding the 316 ss Coil is efficient with:

Tips:

Our 316 steel coil manufacturers offer pre-processed options for convenience.

We sourced 316 cold rolled stainless steel coil for a marine project. The corrosion resistance was phenomenal, and the delivery was spot on. Great distributor!

Paul H.

Marine Engineer

The 316 stainless steel hot rolled coil we ordered for our chemical tanks was flawless. Quality and service from this company are unmatched!

Anna K.

Process Manager

Using ss 316 coil for food equipment was a smart choice. Durable and easy to work with – highly recommend this manufacturer!

Greg M.

Equipment Designer

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.