Get in touch with us

Leave a message

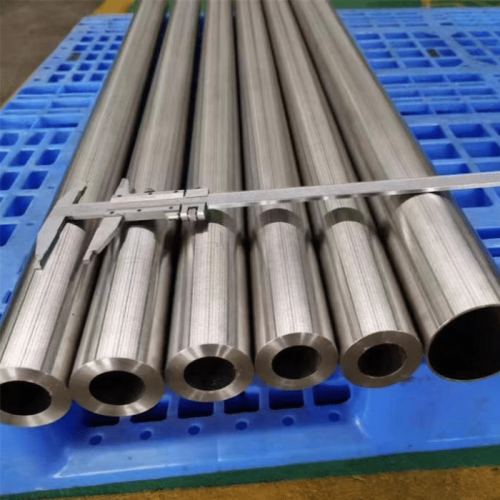

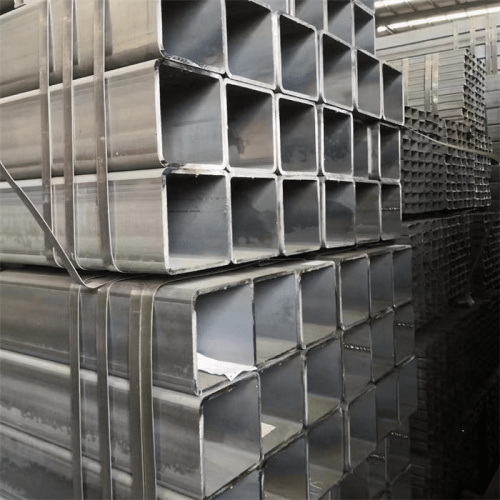

Need specific 304 stainless steel Tube sizes? Our China factory offers tailored options!

Its uses are vast from 304 steel tubing in manufacturing to 304 corrugated stainless steel tubing in HVAC.

| Element | Percentage (%) |

|---|---|

| Carbon (C) | ≤ 0.08 |

| Chromium (Cr) | 18.0–20.0 |

| Nickel (Ni) | 8.0–10.5 |

| Manganese (Mn) | ≤ 2.0 |

| Silicon (Si) | ≤ 1.0 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.03 |

| Iron (Fe) | Balance |

| Property | Value |

|---|---|

| Tensile Strength | 515–690 MPa |

| Yield Strength (0.2%) | ≥ 205 MPa |

| Elongation | ≥ 40% |

| Hardness (Brinell) | ≤ 201 HB |

| Density | 8.0 g/cm³ |

The 304 Stainless Steel Tube resists:

Our China distributor can suggest alternatives if needed.

| Environment | Corrosion Resistance | Notes |

|---|---|---|

| Atmospheric (Urban/Rural) | Excellent | Resists rust in typical outdoor conditions. |

| Fresh Water | Excellent | Ideal for non-chlorinated water systems. |

| Mild Chemicals | Good | Handles dilute acids and cleaners effectively. |

| Saltwater (Coastal) | Moderate | Prone to pitting with prolonged saline exposure. |

| Industrial Atmospheres | Good | Resists mild pollutants; monitor heavy exposure. |

Contact us for detailed corrosion resistance data specific to your application.

Welding 304 Stainless Steel Tube is efficient:

Tips:

Our 304 Pipe Cutting services simplify fabrication.

John K.

Plumber

Sarah M.

Facility Manager

Mike T.

Mechanic

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.